loading

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-2000 |

| Minimum Order Quantity | 1set |

| Price | negotiation |

| Packaging Details | FOAM AND CARTON |

| Delivery Time | 3DAYS |

| Payment Terms | T/T, Western Union, MoneyGram |

| Supply Ability | 200 SETS PER MONTH |

| Frequency | 15K~60K | Power | 300W~3200W |

|---|---|---|---|

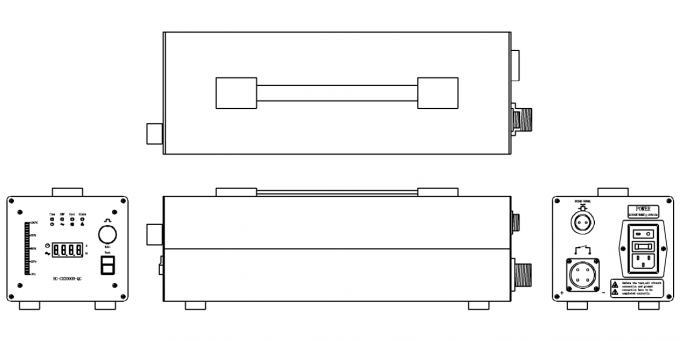

| Type | Digital Generator | Size | 120*120*380 |

| Voltage | AC220V 50HZ/60HZ. | Frequency Range | +_1frequency |

| High Light | digital ultrasonic generator,ultrasonic frequency generator | ||

Ultrasonic Generator For Ultrasonic Welding, Cutting, And Sealing

Min size:120*120*380

Key components of an ultrasonic welding system include a generator and a resonant stack. The stack has three components: a converter, a booster and a horn.

The generator converts electrical voltage into a high-frequency signal—usually 20 or 40 kilohertz. High power levels necessitate lower frequencies.

The converter, or transducer, consists of piezoelectric crystals attached to a base of aluminum or titanium. It changes high-frequency electrical signals into high-frequency mechanical vibrations. The booster is a mechanical transformer used to transmit vibration from the converter to the horn.

Process variables are very important to ultrasonic welding. Controlling time, force, depth, amplitude and power is critical to making good welds. Microprocessor- and software-based controls allow ultrasonic welders to automatically monitor a wide range of variables to ensure quality and repeatability.

Ultrasonic welders cost anywhere from $18,000 to $45,000, depending on power capacity and bells and whistles, such as statistical process control packages. A basic 20-kilohertz, 2.5- to 3.5-kilowatt ultrasonic metal welding system can be acquired for around $30,000. And, that cost has been coming down in recent years. For instance, machines that used to be priced at more than $40,000 are now available for $30,000 or less.

By comparison, spin welders and thermal stakers are very price competitive with ultrasonics. Resistance welders typically cost between $8,000 and $30,000. Laser welders are $50,000 and up. But, even a high-end resistance welder may not provide the same quality control features as an ultrasonic welder. Sonic weld times are frequently much faster than alternative joining processes.

Mechanical fastening equipment is relatively inexpensive, but the fasteners represent an extra cost that must be factored into any economic analysis. “Riveting requires the highest skill level and longest time and adds weight to a product,” notes Janet Devine, president of Sonobond Ultrasonics (West Chester, PA).

This digital generator is available in frequencies of 15kHz, 20Khz, 28Khz,30 kHz, 35 kHz and 40Khz at a power range between 300 W and 3000 W. Programmable ramp up and ramp down times and infinitely variable adjustment of weld amplitudes are only some of the features of this product line. The biggest advantage of this generator is the wide frenquncy range, for example: the 20Khz generator, it can catch the frequency from 18~21khz, so it is easy to tuning. Also it is easy for some ultrasonic new user.

1, Adopt parallel resonance to drive the converter, reduce the heating of converter to protect it.

2, Button start, easy operation.

3, Imported control chip and driver, makes the ultrasonic generator works more reliable.

4, The frequency based on the PID control and amplitude control, frequency locking and achieve constant amplitude control as well.

5, Explosive power output,compare to traditional ultrasonic generator, our ultrasonic generator only request 1/2 cylinder pressure to achieve the same power output.

6, Amplitude soft start, ensure make use of huge mould.

7, Welding amplitude adjustment range 0~100% by 1%.

8, Multiple protection to ensure the safety of equipment and test-piece.

Characteristic:

Application:

Welding, insertion, bend, spot welding, cutting.

Product material: ABS,PP,PS,SNA,PC,PA,PET, non-woven, nylon, etc.

| Frequency(kHz) | Nmal operating frequency | Our generation operating frequency |

| 28 | 27.80~28.10 | 27.80~30.10 |

| 30 | 29.80~30.00 | |

| 35 | 34.80~34.90 | 34.80~39.95 |

| 40 | 39.85~39.95 |

| Frequency | Power | Rated work current |

| 30KHZ | 800W | 4 A |

| 1200W | 6 A | |

| 35KHZ | 800W | 4 A |

| 1200W | 6 A | |

| 15KHZ | 1500W | 8A |

| 3000W | 15A | |

| 20KHZ | 1500W | 8A |

| 3000W | 15A |

| Application | Suitable |

| Welding | Available |

| Sealing | Available |

| Sewing | Available |

| Cutting | Available |

| Sonochemistry | Available , but not the best, If open the equipment when the horn in the liquid , it can catch the frequency well, it is better tracking the frequency without any loading. |

| Metal welding | Available , but not the best. Metal welding always in high loading , it is better use a generator with well ventilation. |

| Atomization | Available |

Available environment temperature: -20C° to 40°C, work over temperature may cause in abnormal operation of the equipment and safety accidents.

Available air humidity: less than 70%. Excessive air humidity may cause Short circuit of the internal electronic components.

Maximum electromagnetic interference intensity: less than 120E. Larger than 120E will cause seriously interfere and damage the equipment.

The power input standard is: single-phase AC220V 50HZ/60HZ.

Input power supply voltage fluctuation range: <10%.

Input power supply harmonic content: <20%.

Input power supply current: 10A.

Input power cord diameter: >1.5MM2.

| Frequency | 15K~60K | Power | 300W~3200W |

|---|---|---|---|

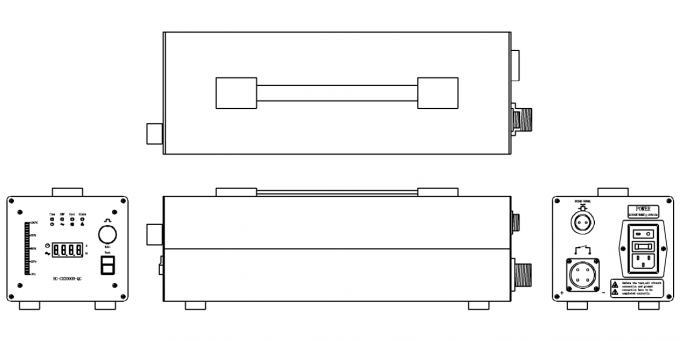

| Type | Digital Generator | Size | 120*120*380 |

| Voltage | AC220V 50HZ/60HZ. | Frequency Range | +_1frequency |

| High Light | digital ultrasonic generator,ultrasonic frequency generator | ||

Ultrasonic Generator For Ultrasonic Welding, Cutting, And Sealing

Min size:120*120*380

Key components of an ultrasonic welding system include a generator and a resonant stack. The stack has three components: a converter, a booster and a horn.

The generator converts electrical voltage into a high-frequency signal—usually 20 or 40 kilohertz. High power levels necessitate lower frequencies.

The converter, or transducer, consists of piezoelectric crystals attached to a base of aluminum or titanium. It changes high-frequency electrical signals into high-frequency mechanical vibrations. The booster is a mechanical transformer used to transmit vibration from the converter to the horn.

Process variables are very important to ultrasonic welding. Controlling time, force, depth, amplitude and power is critical to making good welds. Microprocessor- and software-based controls allow ultrasonic welders to automatically monitor a wide range of variables to ensure quality and repeatability.

Ultrasonic welders cost anywhere from $18,000 to $45,000, depending on power capacity and bells and whistles, such as statistical process control packages. A basic 20-kilohertz, 2.5- to 3.5-kilowatt ultrasonic metal welding system can be acquired for around $30,000. And, that cost has been coming down in recent years. For instance, machines that used to be priced at more than $40,000 are now available for $30,000 or less.

By comparison, spin welders and thermal stakers are very price competitive with ultrasonics. Resistance welders typically cost between $8,000 and $30,000. Laser welders are $50,000 and up. But, even a high-end resistance welder may not provide the same quality control features as an ultrasonic welder. Sonic weld times are frequently much faster than alternative joining processes.

Mechanical fastening equipment is relatively inexpensive, but the fasteners represent an extra cost that must be factored into any economic analysis. “Riveting requires the highest skill level and longest time and adds weight to a product,” notes Janet Devine, president of Sonobond Ultrasonics (West Chester, PA).

This digital generator is available in frequencies of 15kHz, 20Khz, 28Khz,30 kHz, 35 kHz and 40Khz at a power range between 300 W and 3000 W. Programmable ramp up and ramp down times and infinitely variable adjustment of weld amplitudes are only some of the features of this product line. The biggest advantage of this generator is the wide frenquncy range, for example: the 20Khz generator, it can catch the frequency from 18~21khz, so it is easy to tuning. Also it is easy for some ultrasonic new user.

1, Adopt parallel resonance to drive the converter, reduce the heating of converter to protect it.

2, Button start, easy operation.

3, Imported control chip and driver, makes the ultrasonic generator works more reliable.

4, The frequency based on the PID control and amplitude control, frequency locking and achieve constant amplitude control as well.

5, Explosive power output,compare to traditional ultrasonic generator, our ultrasonic generator only request 1/2 cylinder pressure to achieve the same power output.

6, Amplitude soft start, ensure make use of huge mould.

7, Welding amplitude adjustment range 0~100% by 1%.

8, Multiple protection to ensure the safety of equipment and test-piece.

Characteristic:

Application:

Welding, insertion, bend, spot welding, cutting.

Product material: ABS,PP,PS,SNA,PC,PA,PET, non-woven, nylon, etc.

| Frequency(kHz) | Nmal operating frequency | Our generation operating frequency |

| 28 | 27.80~28.10 | 27.80~30.10 |

| 30 | 29.80~30.00 | |

| 35 | 34.80~34.90 | 34.80~39.95 |

| 40 | 39.85~39.95 |

| Frequency | Power | Rated work current |

| 30KHZ | 800W | 4 A |

| 1200W | 6 A | |

| 35KHZ | 800W | 4 A |

| 1200W | 6 A | |

| 15KHZ | 1500W | 8A |

| 3000W | 15A | |

| 20KHZ | 1500W | 8A |

| 3000W | 15A |

| Application | Suitable |

| Welding | Available |

| Sealing | Available |

| Sewing | Available |

| Cutting | Available |

| Sonochemistry | Available , but not the best, If open the equipment when the horn in the liquid , it can catch the frequency well, it is better tracking the frequency without any loading. |

| Metal welding | Available , but not the best. Metal welding always in high loading , it is better use a generator with well ventilation. |

| Atomization | Available |

Available environment temperature: -20C° to 40°C, work over temperature may cause in abnormal operation of the equipment and safety accidents.

Available air humidity: less than 70%. Excessive air humidity may cause Short circuit of the internal electronic components.

Maximum electromagnetic interference intensity: less than 120E. Larger than 120E will cause seriously interfere and damage the equipment.

The power input standard is: single-phase AC220V 50HZ/60HZ.

Input power supply voltage fluctuation range: <10%.

Input power supply harmonic content: <20%.

Input power supply current: 10A.

Input power cord diameter: >1.5MM2.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!