loading

| Availability: | |

|---|---|

| Quantity: | |

RPS-SONIC

| Place of Origin | CHINA |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-C40 |

| Minimum Order Quantity | 1SET |

| Price | negotiation |

| Packaging Details | FOAM AND CARTON |

| Delivery Time | 3DAYS |

| Payment Terms | T/T, Western Union, MoneyGram, PAYPAL |

| Supply Ability | 500 SETS PER MONTH |

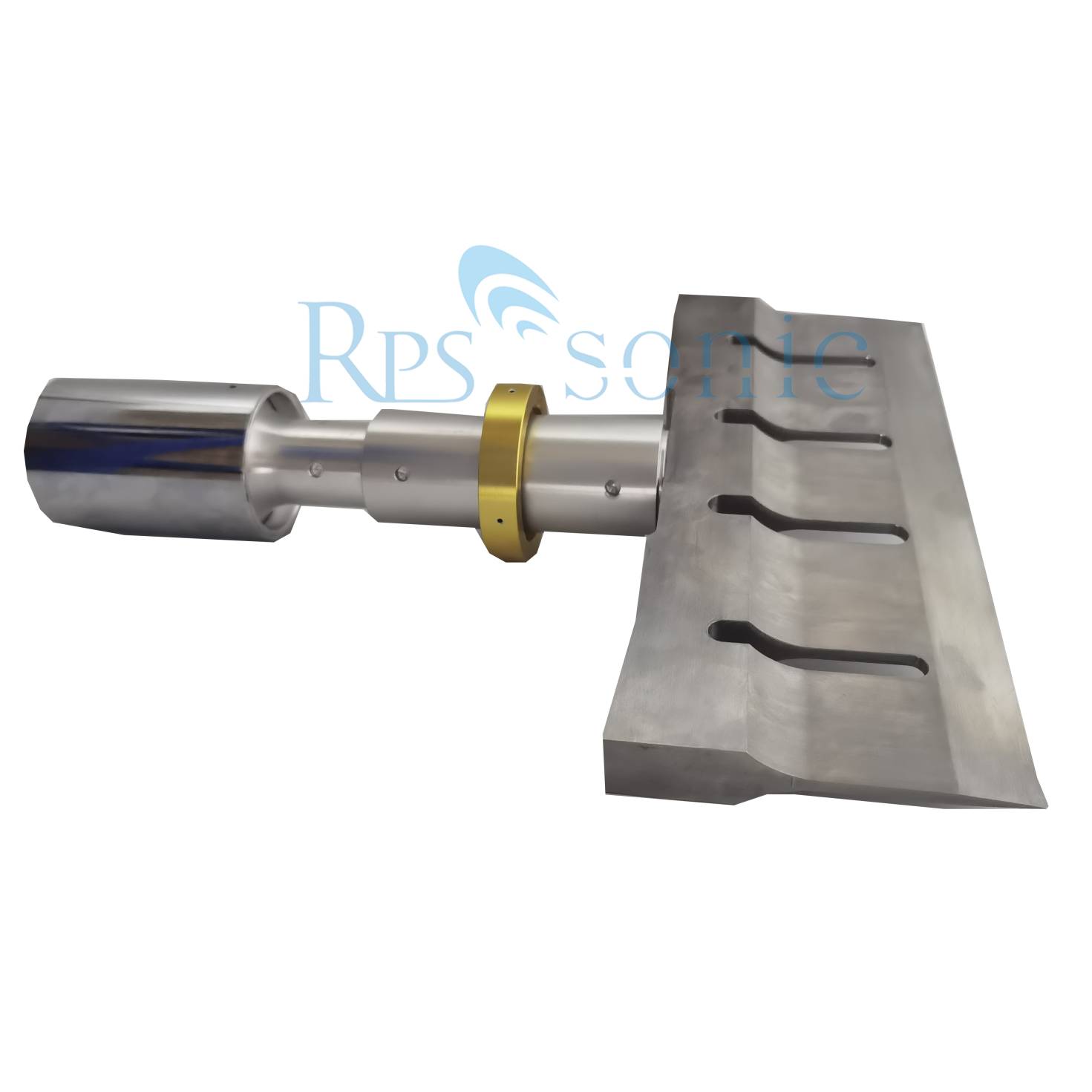

| Name | Ultrasonic Cutting Pencil | Frequency | 20Khz |

|---|---|---|---|

| Power | 2000w | Type | Metal Housing |

| Horn | Titanium | Blade | 380mm |

| High Light | ultrasonic cutting machine,portable ultrasonic cutter | ||

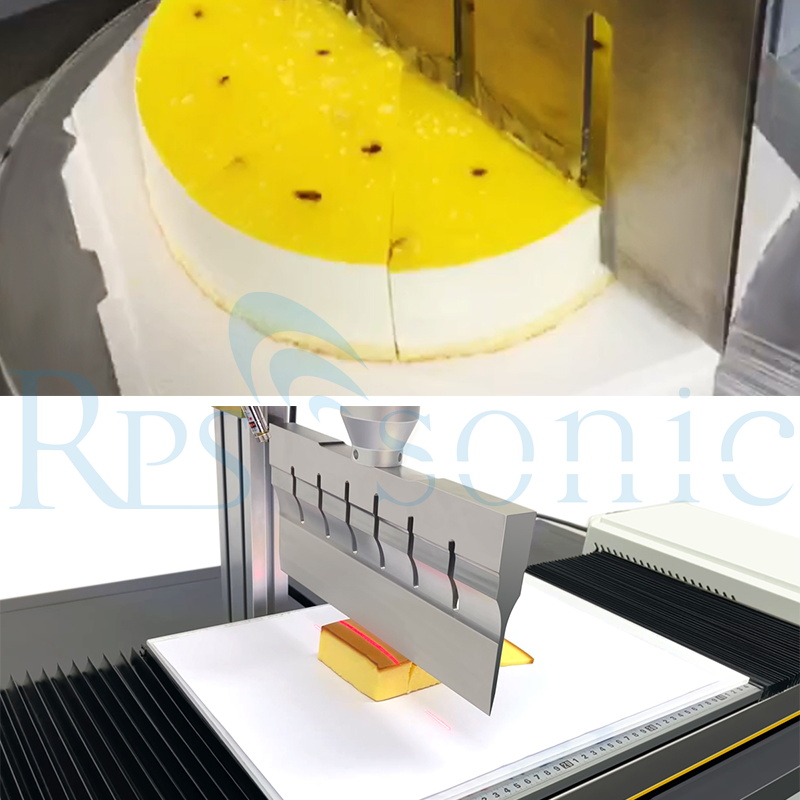

Easy Cleaning Ultrasonic cheese portioning for all shapes cheese cutting

Our ultrasonic cutting blades, ultrasonic knifes, ultrasonic horns or sonotrodes are increasingly used in the food industry within food processing machines either for ultrasonic cutting, ultrasonic slicing, ultrasonic portioning or ultrasonic dicing food such as : cheese slicing, pastry cutting, cake portioning, pie slicing, servings cutting , deli portioning, meat cutting, bacon slicing or even frozen food cutting.

Ability to cut products at various temperatures – frozen / chilled / ambient.

Easy to clean – designed with hygiene in mind.

Welcome automation ultrasonics cutting systerm cooperate with us all over the world.

| Machine | Ultrasonic rubber/cake Cutter |

| Frequency(KHz) | 20Khz |

| Power | 2000 W |

| Cutting Blade / Horn | Titanium |

| Voltage(V) | 220V |

| The width of blade | depend on your requirement |

| Cutting thickness | 10~20mm(depend on materials) |

| Horn amplitude | 10-40μm |

| Equipment weight | 1KG |

With advantages such as having excellent cut face, reduced smearing, low product lost, less deformation, less tendency to shatter for brittle products, and being able to handle sticky or brittle foods, ultrasonic cutting has become increasingly popular in the food processing industry in recent years. Although a number of publications have documented the use of ultrasound to cut food with an improved end-product quality, all previous works were focused on ultrasound or mechanical aspects of cutting process. No study has been published to investigating the effect of ultrasound cutting on food quality during storage. My thesis research was conducted to investigate the effect of ultrasound amplitude on the surface appearance and quality of selected cheese (Cheddar, mozzarella, and Swiss cheese) and fresh cut apples (red delicious and golden delicious) during storage. To examine the effect of ultrasonic cutting on quality of cheese products, cheddar, mozzarella, and Swiss cheeses were chosen because of their popularity. The focus of the investigation was on quality changes of cheese samples cut with ultrasound and without ultrasound in three-weeks of storage. Quality attributes such as total color difference, surface topography, peroxide values, pH, and sensory characteristics (taste, odor, and overall acceptability) of the samples were compared. General chemical parameters in ultrasonic cut samples including lipid oxidation and pH value showed significant differences from that of the Control. In addition, the L (lightness) values of samples cut with and without ultrasound were significantly different. Furthermore, all cheeses cut with ultrasound showed shiny and smooth surface appearance, while the surfaces were relatively rough for samples cut without ultrasound. The microscope images indicated that ultrasonic cutting resulted in a smoother surface compared to the Control. In the experiments with apples, red delicious and golden delicious apples were used because of their popular use in fresh-cut apples and the rapid browning of slices (especially red delicious apple which has a high susceptibility to browning) after preparation. The quality of apple samples cut with and without ultrasound was evaluated for a period of two weeks. A significant difference in polyphenol oxidase activity and pH levels was found between samples cut with and without ultrasound. The L (lightness) values of apples cut with ultrasound were significantly higher than that in the Control. Furthermore, both types of apples cut with ultrasound exhibited smooth surface appearance, while the surfaces were relatively rough for samples cut without ultrasound. The environmental scanning electron microscope images indicated that ultrasonic cutting resulted in a smoother surface compared to the Control.

Ultrasonic Components

1.Stackable, ultrasonic power supplies and panel mount generator kits

2.Rigid mount ultrasonic boosters for improved stack stability

3.Wash-down duty, air-cooled converters (stainless steel body also available)

4.Food industry approved titanium blade,slitting and knife horns

Typical ultrasonic food cutting components include four major elements: a power supply, a converter, a booster and a cutting horn, as explained below.

Applications:

Round Cheese

Block Cheese

Extruded Cheese

Cake

Nougat

| Name | Ultrasonic Cutting Pencil | Frequency | 20Khz |

|---|---|---|---|

| Power | 2000w | Type | Metal Housing |

| Horn | Titanium | Blade | 380mm |

| High Light | ultrasonic cutting machine,portable ultrasonic cutter | ||

Easy Cleaning Ultrasonic cheese portioning for all shapes cheese cutting

Our ultrasonic cutting blades, ultrasonic knifes, ultrasonic horns or sonotrodes are increasingly used in the food industry within food processing machines either for ultrasonic cutting, ultrasonic slicing, ultrasonic portioning or ultrasonic dicing food such as : cheese slicing, pastry cutting, cake portioning, pie slicing, servings cutting , deli portioning, meat cutting, bacon slicing or even frozen food cutting.

Ability to cut products at various temperatures – frozen / chilled / ambient.

Easy to clean – designed with hygiene in mind.

Welcome automation ultrasonics cutting systerm cooperate with us all over the world.

| Machine | Ultrasonic rubber/cake Cutter |

| Frequency(KHz) | 20Khz |

| Power | 2000 W |

| Cutting Blade / Horn | Titanium |

| Voltage(V) | 220V |

| The width of blade | depend on your requirement |

| Cutting thickness | 10~20mm(depend on materials) |

| Horn amplitude | 10-40μm |

| Equipment weight | 1KG |

With advantages such as having excellent cut face, reduced smearing, low product lost, less deformation, less tendency to shatter for brittle products, and being able to handle sticky or brittle foods, ultrasonic cutting has become increasingly popular in the food processing industry in recent years. Although a number of publications have documented the use of ultrasound to cut food with an improved end-product quality, all previous works were focused on ultrasound or mechanical aspects of cutting process. No study has been published to investigating the effect of ultrasound cutting on food quality during storage. My thesis research was conducted to investigate the effect of ultrasound amplitude on the surface appearance and quality of selected cheese (Cheddar, mozzarella, and Swiss cheese) and fresh cut apples (red delicious and golden delicious) during storage. To examine the effect of ultrasonic cutting on quality of cheese products, cheddar, mozzarella, and Swiss cheeses were chosen because of their popularity. The focus of the investigation was on quality changes of cheese samples cut with ultrasound and without ultrasound in three-weeks of storage. Quality attributes such as total color difference, surface topography, peroxide values, pH, and sensory characteristics (taste, odor, and overall acceptability) of the samples were compared. General chemical parameters in ultrasonic cut samples including lipid oxidation and pH value showed significant differences from that of the Control. In addition, the L (lightness) values of samples cut with and without ultrasound were significantly different. Furthermore, all cheeses cut with ultrasound showed shiny and smooth surface appearance, while the surfaces were relatively rough for samples cut without ultrasound. The microscope images indicated that ultrasonic cutting resulted in a smoother surface compared to the Control. In the experiments with apples, red delicious and golden delicious apples were used because of their popular use in fresh-cut apples and the rapid browning of slices (especially red delicious apple which has a high susceptibility to browning) after preparation. The quality of apple samples cut with and without ultrasound was evaluated for a period of two weeks. A significant difference in polyphenol oxidase activity and pH levels was found between samples cut with and without ultrasound. The L (lightness) values of apples cut with ultrasound were significantly higher than that in the Control. Furthermore, both types of apples cut with ultrasound exhibited smooth surface appearance, while the surfaces were relatively rough for samples cut without ultrasound. The environmental scanning electron microscope images indicated that ultrasonic cutting resulted in a smoother surface compared to the Control.

Ultrasonic Components

1.Stackable, ultrasonic power supplies and panel mount generator kits

2.Rigid mount ultrasonic boosters for improved stack stability

3.Wash-down duty, air-cooled converters (stainless steel body also available)

4.Food industry approved titanium blade,slitting and knife horns

Typical ultrasonic food cutting components include four major elements: a power supply, a converter, a booster and a cutting horn, as explained below.

Applications:

Round Cheese

Block Cheese

Extruded Cheese

Cake

Nougat

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment