loading

| Availability: | |

|---|---|

| Quantity: | |

RPS-C20-305

| Place of Origin | CHINA |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-C40 |

| Minimum Order Quantity | 1SET |

| Price | negotiation |

| Packaging Details | FOAM AND CARTON |

| Delivery Time | 3DAYS |

| Payment Terms | T/T, Western Union, MoneyGram, PAYPAL |

| Supply Ability | 500 SETS PER MONTH |

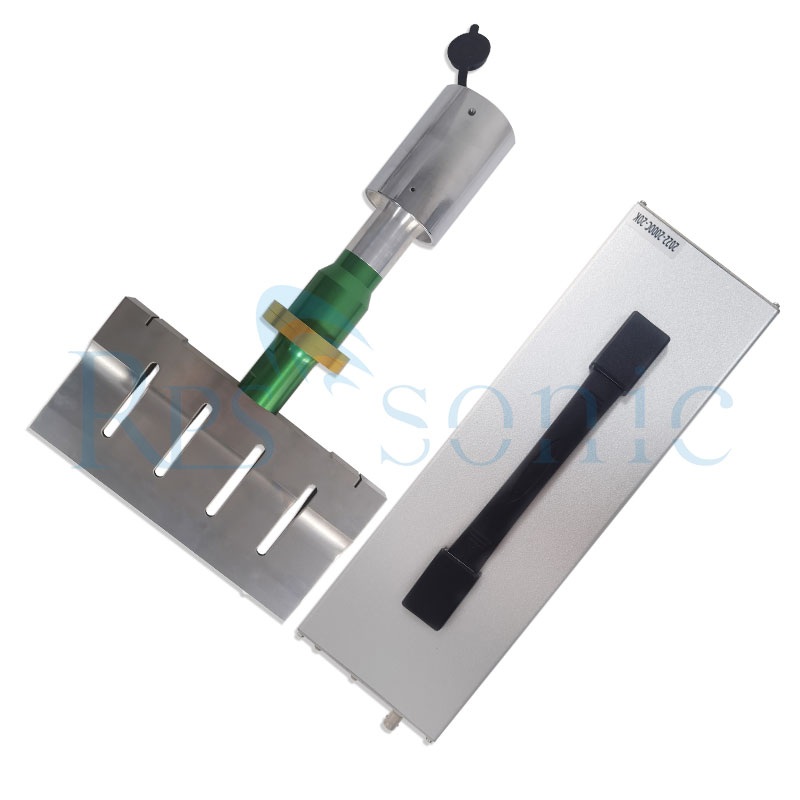

| Name | Ultrasonic Cake Cutting Machine | Frequency | 20Khz |

|---|---|---|---|

| Power | 1000w | Type | Pencil Type, Metal Housing |

| Horn | Titanium | Housing | Metal Housing |

| High Light | portable ultrasonic cutter,ultrasonic food cutter | ||

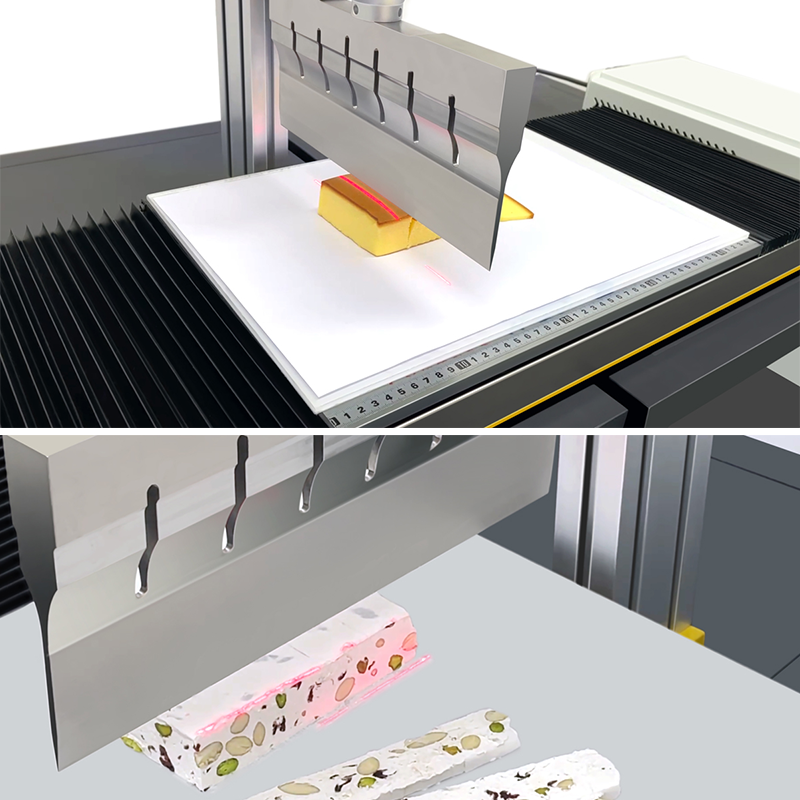

Ultrasonic cheese cutting utilizes a knife vibrating at a high frequency, which produces a nearly frictionless surface, thus preventing cheese from deforming or sticking to the knife. RPS-SONIC Design & Manufacturing has the technology to satisfy your ultrasonic cheese cutting needs.Our ultrasonic cutting blades, ultrasonic knifes, ultrasonic horns or sonotrodes are increasingly used in the food industry within food processing machines either for ultrasonic cutting, ultrasonic slicing, ultrasonic portioning or ultrasonic dicing food such as : cheese slicing, pastry cutting, cake portioning, pie slicing, servings cutting , deli portioning, meat cutting, bacon slicing or even frozen food cutting.

Our titanium sonotrodes can be either of corner type, half wavelength or full wavelength, and because we design and manufacture them by ourself, they are of best quality and economical at the same time.

Because of our extended experience with any kind of ultrasonic blade, generator and booster, We are used to deal with all kinds of them, so we are available to help you throughout the process of choosing the right blade (knife, horn or sonotrode) to replace your previous one within your own slicing machine, and get a full compatibility with your own equipment.

Application:

With the latest ultrasonic cutting technology, we can provide our customers solutions to cleaner, consistent cutting and a wide range of cutting temperatures and products. All machines are sanitary in design for the food industry and are wash down safe

Bakery & Snack Foods

Prepared Meats

Soft and Hard Cheese

Health and Granola Bars

Candy and Confectionary

Frozen Fish

Bread and Dough Scoring

Pet Foods and Snacks

Advantages

• High cutting accuracy, no deformation of the compound

• High speed, high efficiency, no pollution

• Cutting surface finish is good, good bonding performance

• Easy to use in automated production

| Machine | Ultrasonic rubber/cake Cutter |

| Frequency(KHz) | 40KHz/20Khz |

| Power | 500 W |

| Cutting Blade / Horn | Titanium |

| Voltage(V) | 220V |

| The width of blade | depend on your requirement |

| Cutting thickness | 10~20mm(depend on materials) |

| Horn amplitude | 10-40μm |

| Equipment weight | 0.6KG |

The Ultrasonic Cutting Systems can easily cut to Food ( Cakes, Pies, Fish, Snack, Meat, baked Cookies, Cheese, Vegetable, Candy, Confectionery, Ice Cream) Rubber, Tyre, Resin, Cloths Non-Woven, Film, Ribbon, CD, Foam, Cardboard, Bonded Textile, Craft items, Glass and composite material in which various products.

The Ultrasonic cutting horn, which is vibrating at a high frequency, creates a nearly friction-free environment between the horn and the product, its blade vibrate with an amplitude of 10-70 µm in the longitudinal friction. The vibration is microscopic, so it cannot be seen The movement repeats 20,000 times per seconds ( 20 Khz ).

| Name | Ultrasonic Cake Cutting Machine | Frequency | 20Khz |

|---|---|---|---|

| Power | 1000w | Type | Pencil Type, Metal Housing |

| Horn | Titanium | Housing | Metal Housing |

| High Light | portable ultrasonic cutter,ultrasonic food cutter | ||

Ultrasonic cheese cutting utilizes a knife vibrating at a high frequency, which produces a nearly frictionless surface, thus preventing cheese from deforming or sticking to the knife. RPS-SONIC Design & Manufacturing has the technology to satisfy your ultrasonic cheese cutting needs.Our ultrasonic cutting blades, ultrasonic knifes, ultrasonic horns or sonotrodes are increasingly used in the food industry within food processing machines either for ultrasonic cutting, ultrasonic slicing, ultrasonic portioning or ultrasonic dicing food such as : cheese slicing, pastry cutting, cake portioning, pie slicing, servings cutting , deli portioning, meat cutting, bacon slicing or even frozen food cutting.

Our titanium sonotrodes can be either of corner type, half wavelength or full wavelength, and because we design and manufacture them by ourself, they are of best quality and economical at the same time.

Because of our extended experience with any kind of ultrasonic blade, generator and booster, We are used to deal with all kinds of them, so we are available to help you throughout the process of choosing the right blade (knife, horn or sonotrode) to replace your previous one within your own slicing machine, and get a full compatibility with your own equipment.

Application:

With the latest ultrasonic cutting technology, we can provide our customers solutions to cleaner, consistent cutting and a wide range of cutting temperatures and products. All machines are sanitary in design for the food industry and are wash down safe

Bakery & Snack Foods

Prepared Meats

Soft and Hard Cheese

Health and Granola Bars

Candy and Confectionary

Frozen Fish

Bread and Dough Scoring

Pet Foods and Snacks

Advantages

• High cutting accuracy, no deformation of the compound

• High speed, high efficiency, no pollution

• Cutting surface finish is good, good bonding performance

• Easy to use in automated production

| Machine | Ultrasonic rubber/cake Cutter |

| Frequency(KHz) | 40KHz/20Khz |

| Power | 500 W |

| Cutting Blade / Horn | Titanium |

| Voltage(V) | 220V |

| The width of blade | depend on your requirement |

| Cutting thickness | 10~20mm(depend on materials) |

| Horn amplitude | 10-40μm |

| Equipment weight | 0.6KG |

The Ultrasonic Cutting Systems can easily cut to Food ( Cakes, Pies, Fish, Snack, Meat, baked Cookies, Cheese, Vegetable, Candy, Confectionery, Ice Cream) Rubber, Tyre, Resin, Cloths Non-Woven, Film, Ribbon, CD, Foam, Cardboard, Bonded Textile, Craft items, Glass and composite material in which various products.

The Ultrasonic cutting horn, which is vibrating at a high frequency, creates a nearly friction-free environment between the horn and the product, its blade vibrate with an amplitude of 10-70 µm in the longitudinal friction. The vibration is microscopic, so it cannot be seen The movement repeats 20,000 times per seconds ( 20 Khz ).

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment