loading

| Availability: | |

|---|---|

| Quantity: | |

RPS-C20-305

RPS-SONIC

| Place of Origin | CHINA |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-C40 |

| Minimum Order Quantity | 1SET |

| Price | negotiation |

| Packaging Details | FOAM AND CARTON |

| Delivery Time | 3DAYS |

| Payment Terms | T/T, Western Union, MoneyGram, PAYPAL |

| Supply Ability | 500 SETS PER MONTH |

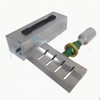

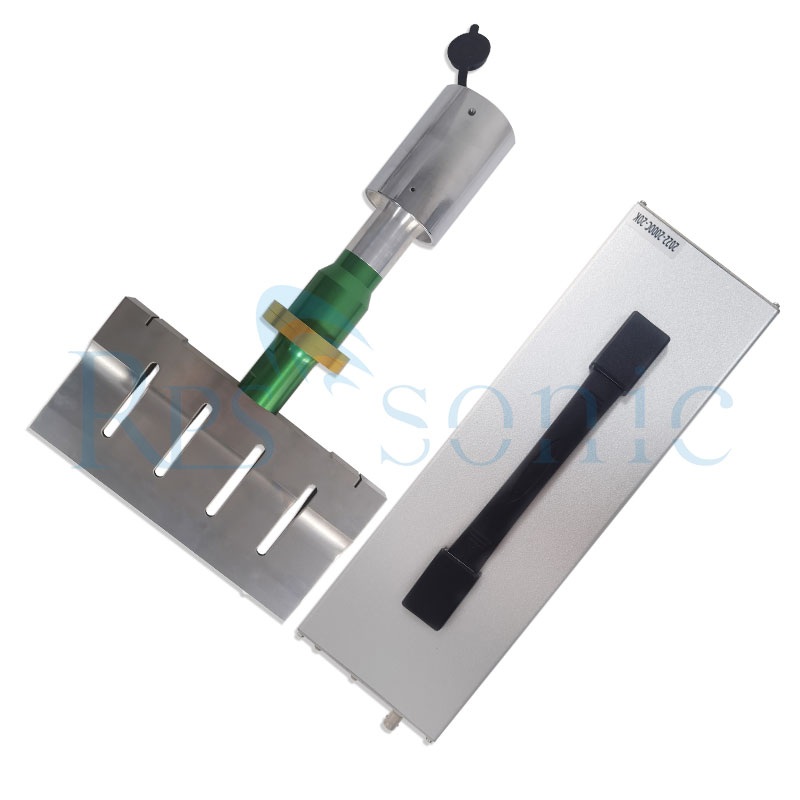

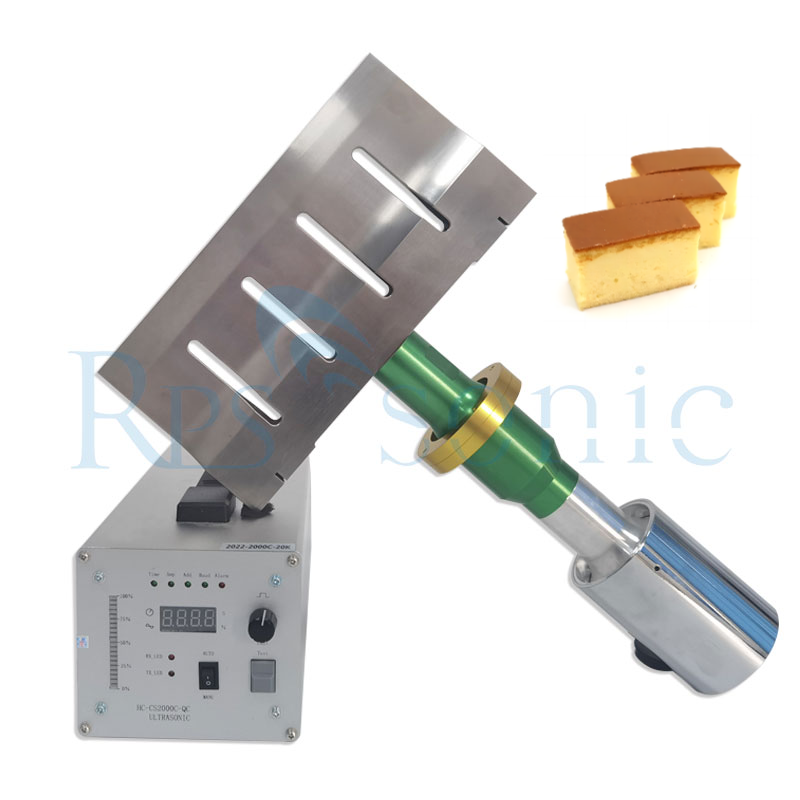

| Name | Ultrasonic Cutting Pencil | Frequency | 20Khz |

|---|---|---|---|

| Power | 1000w | Type | Pencil Type, Metal Housing |

| Power Supply | AC200V 50/60Hz | Generator Size | 120*120*380 |

| High Light | ultrasonic cutting machine,ultrasonic food cutter | ||

Cut the capsules easily and without burrs. Ultrasonic cutting knives are mounted crosswise on the robotic arm and the rapid flow operation cuts the capsules..This application are desgined by HC-SONIC for Hangzhou ****medical Co.,ltd. There is Industry confidential information, so can't public it on the website. But if you need more equipment information , please email us.

Also we can desgin a cutting program for you also. We can desgin many cutting program for all customer without any fee. But we need your enough sample to do the test.

This Ultrasonic Cutter is designed compact and lightweight with an easy hand grip to reduce fatigue allowing for long continuous operation. This ideal handpiece offers excellent maneuverability with no vibration to the hand ensuring an accurate and sharp cutting finish. The controller automatically adjusts the output power depending on the load so there is no need to make any adjustments on the controller during the working process. A constant frequency provides steady cutting results. From simple work to fine cutting and complicated shapes, this Ultrasonic cutting Knife performs effortlessly and beautifully.

Ultrasonic rubber cutting equipment is a rubber cutting device, its main function is to help customers quickly cut rubber, artificial cutting efficiency is ten times more than the quality of the crop is more than three times the normal round knife. Such a high-efficiency ultrasonic rubber cutting equipment is to rubber production specialized production of ultrasonic rubber cutting equipment advent of saving a lot of labor costs, greatly improving the cutting efficiency, improve tool life 3--5 years.

1. Cut the material quickly and precisely

2. Smooth and traceless cutting edge

3. Powerful, effective realiable

4. Low cost, easy operator. An operator only handle the probe and step the foot switch .So anybody can use it easily.

Applications:

1. For thermal plastic gate cutting and flush cutting.

2. For non-woven or woven cutting,textile cutting, fabric cutter, curtain cutting,window blind fabric

3. For rubber, PVC, leather plastic, cardboard, acrylic, polyprolene and so on cutting.

4. For tape and film cutting .

5. For paper cutting,printing industry cutting.

6. For package material cutting

7. For the automotive industry cutting

| Frequency | 20Khz |

|---|---|

| Frequency adjustment | Auto-tracking type |

| Max. power output | 1000W |

| Power output | Infinitive adjustment |

| Power supply | AC200V 50/60Hz |

| Electricity consumption | 1000VA |

| Outer dimension (mm) | 120*120*380 |

| External control | on/off, Emergency stop, Change of output |

| Weight | 8kg |

| Blade thickness | 0.6mm |

Target Materials

Resin plate

Glass fiber (GFRP)

Formed decorative film

Foam

Blow-molded parts

Injection-molded parts

Carbon fiber (CFRP)

Aluminum foil composites

Non-woven fabrics

Controlled-depth kiss cutting

| Name | Ultrasonic Cutting Pencil | Frequency | 20Khz |

|---|---|---|---|

| Power | 1000w | Type | Pencil Type, Metal Housing |

| Power Supply | AC200V 50/60Hz | Generator Size | 120*120*380 |

| High Light | ultrasonic cutting machine,ultrasonic food cutter | ||

Cut the capsules easily and without burrs. Ultrasonic cutting knives are mounted crosswise on the robotic arm and the rapid flow operation cuts the capsules..This application are desgined by HC-SONIC for Hangzhou ****medical Co.,ltd. There is Industry confidential information, so can't public it on the website. But if you need more equipment information , please email us.

Also we can desgin a cutting program for you also. We can desgin many cutting program for all customer without any fee. But we need your enough sample to do the test.

This Ultrasonic Cutter is designed compact and lightweight with an easy hand grip to reduce fatigue allowing for long continuous operation. This ideal handpiece offers excellent maneuverability with no vibration to the hand ensuring an accurate and sharp cutting finish. The controller automatically adjusts the output power depending on the load so there is no need to make any adjustments on the controller during the working process. A constant frequency provides steady cutting results. From simple work to fine cutting and complicated shapes, this Ultrasonic cutting Knife performs effortlessly and beautifully.

Ultrasonic rubber cutting equipment is a rubber cutting device, its main function is to help customers quickly cut rubber, artificial cutting efficiency is ten times more than the quality of the crop is more than three times the normal round knife. Such a high-efficiency ultrasonic rubber cutting equipment is to rubber production specialized production of ultrasonic rubber cutting equipment advent of saving a lot of labor costs, greatly improving the cutting efficiency, improve tool life 3--5 years.

1. Cut the material quickly and precisely

2. Smooth and traceless cutting edge

3. Powerful, effective realiable

4. Low cost, easy operator. An operator only handle the probe and step the foot switch .So anybody can use it easily.

Applications:

1. For thermal plastic gate cutting and flush cutting.

2. For non-woven or woven cutting,textile cutting, fabric cutter, curtain cutting,window blind fabric

3. For rubber, PVC, leather plastic, cardboard, acrylic, polyprolene and so on cutting.

4. For tape and film cutting .

5. For paper cutting,printing industry cutting.

6. For package material cutting

7. For the automotive industry cutting

| Frequency | 20Khz |

|---|---|

| Frequency adjustment | Auto-tracking type |

| Max. power output | 1000W |

| Power output | Infinitive adjustment |

| Power supply | AC200V 50/60Hz |

| Electricity consumption | 1000VA |

| Outer dimension (mm) | 120*120*380 |

| External control | on/off, Emergency stop, Change of output |

| Weight | 8kg |

| Blade thickness | 0.6mm |

Target Materials

Resin plate

Glass fiber (GFRP)

Formed decorative film

Foam

Blow-molded parts

Injection-molded parts

Carbon fiber (CFRP)

Aluminum foil composites

Non-woven fabrics

Controlled-depth kiss cutting

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment