loading

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-S35 |

| Minimum Order Quantity | 1 |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 5 WORK DAYS |

| Payment Terms | T/T |

| Supply Ability | 100SET/,YEAR |

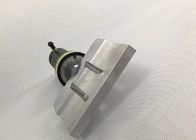

| Frequency | 35Khz | Power | 800W |

|---|---|---|---|

| Generator | Digital Generator | Suitable Apply | Ultrasonic Fabric Sealing Equipment |

| Horn | Al Horn | Suitable Material | Fabric, Nonwoven |

| High Light | Ultrasonic fabric sealing equipment horn,Ultrasonic sealing horn | ||

Ultrasonic products offer clean, consistent and fast processing for joining and cutting nonwoven materials. From quilting mattress pads and sewing disposable health care apparels to slitting and bonding hygiene products we have designed and delivered a solution for all major film and fabric applications. We can accommodate your specific needs to design and build the optimal solution for your material thicknesses and widths, feed rates and material handling requirements. Our technical experts are just a phone call away to answer questions on issues such as: continuous operation and importance of proper cooling; premature tool wear and the benefits of carbide and titanium; material handling logistics, coordination and flow; automation, control and monitoring requirements; required throughput and maximum quality feed rates. Our Fabric & Film Technical Center offers a complete range of services: applications engineering, tooling design, systems integration, service and support, and training. Most important, the Tech Center is your resource for information gathering and experimentation on any of our fully operational ultrasonic machines.

Advantages of Ultrasonic Sealing

| Item | parameter |

| Frequency | 35Khz |

| Power | 800W in max |

| Generator | digital generator |

| Voltage | 220-240V 50/60 Hz |

| Horn material | Aluminum alloy |

| Application | Medical plasctic tube, cosmetic plastic tube Toothpaste tube |

| Welding material | Fabric, nonwoven |

Principles of Operation

Every ultrasonic unit contains the following five elements:

1. A POWER SUPPLY which takes line power at 50 or 60 cycles and changes it to high ultrasonic frequency at 20,000 cycles per second or even higher.

2. A CONVERTER which contains piezoelectric crystals which change the incoming high frequency electrical signal to mechanical vibration.

3. A BOOSTER which transmits the vibration energy and serves to increase its amplitude in much the same way as volume control on a radio.

4. A HORN which delivers the vibration energy to the plastic film or fabric to be worked on.

5. AN ANVIL or backup part which supports the work piece and, in the case of textiles, takes the form of a pattern wheel or non-rotating cutter wheel depending on the application.

The ultrasonic vibration is transmitted from the horn to the material. developing frictional heat where they touch. This momentary heat fuses the edges of the fabric. If double plies are present, the plies join together. Where a cutting edge is used on the anvil, the fabric is cut through and the edges sealed at the same time.

| Frequency | 35Khz | Power | 800W |

|---|---|---|---|

| Generator | Digital Generator | Suitable Apply | Ultrasonic Fabric Sealing Equipment |

| Horn | Al Horn | Suitable Material | Fabric, Nonwoven |

| High Light | Ultrasonic fabric sealing equipment horn,Ultrasonic sealing horn | ||

Ultrasonic products offer clean, consistent and fast processing for joining and cutting nonwoven materials. From quilting mattress pads and sewing disposable health care apparels to slitting and bonding hygiene products we have designed and delivered a solution for all major film and fabric applications. We can accommodate your specific needs to design and build the optimal solution for your material thicknesses and widths, feed rates and material handling requirements. Our technical experts are just a phone call away to answer questions on issues such as: continuous operation and importance of proper cooling; premature tool wear and the benefits of carbide and titanium; material handling logistics, coordination and flow; automation, control and monitoring requirements; required throughput and maximum quality feed rates. Our Fabric & Film Technical Center offers a complete range of services: applications engineering, tooling design, systems integration, service and support, and training. Most important, the Tech Center is your resource for information gathering and experimentation on any of our fully operational ultrasonic machines.

Advantages of Ultrasonic Sealing

| Item | parameter |

| Frequency | 35Khz |

| Power | 800W in max |

| Generator | digital generator |

| Voltage | 220-240V 50/60 Hz |

| Horn material | Aluminum alloy |

| Application | Medical plasctic tube, cosmetic plastic tube Toothpaste tube |

| Welding material | Fabric, nonwoven |

Principles of Operation

Every ultrasonic unit contains the following five elements:

1. A POWER SUPPLY which takes line power at 50 or 60 cycles and changes it to high ultrasonic frequency at 20,000 cycles per second or even higher.

2. A CONVERTER which contains piezoelectric crystals which change the incoming high frequency electrical signal to mechanical vibration.

3. A BOOSTER which transmits the vibration energy and serves to increase its amplitude in much the same way as volume control on a radio.

4. A HORN which delivers the vibration energy to the plastic film or fabric to be worked on.

5. AN ANVIL or backup part which supports the work piece and, in the case of textiles, takes the form of a pattern wheel or non-rotating cutter wheel depending on the application.

The ultrasonic vibration is transmitted from the horn to the material. developing frictional heat where they touch. This momentary heat fuses the edges of the fabric. If double plies are present, the plies join together. Where a cutting edge is used on the anvil, the fabric is cut through and the edges sealed at the same time.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!