loading

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-2000 |

| Minimum Order Quantity | 1 |

| Packaging Details | CARTON450*270*200MM |

| Delivery Time | 3 work days after payment |

| Payment Terms | T/T, Western Union, MoneyGram |

| Supply Ability | 100 |

| High Light | ultrasonic slice machine,ultrasonic medical mask spot welder | ||

|---|---|---|---|

*With best PZT8 in China

*The impedance of the transducer is less than 8 and the impedance of the transducer and welding horn is less than 40.

*5times test for ultrasonic check

*3hours Temperature rise detection

*To confirm all your transducer with horn no matching problem.

| Item | Parameter |

| Frequency | 20KHZ |

| Power | 2000W |

| Horn size | 110*20 OR 150*35mm |

| Horn material | Steel or Aluminum |

| weight | 14.5kg |

Intelligent fan control: When the temperature is low, the fan starts following the ultrasonic output. If there is no ultrasonic output within 30 seconds, the fan stops to prevent inhalation of excessive dust and improve the reliability of the device.When the high temperature exceeds 45 ° C, the fan will continue to work to cool down.When the temperature exceeds 80 ° C, the device will provide over-temperature protection and prompt on the screen.Power limitation: In order to be able to work continuously around 2000W, the actual power protection threshold of the generator is 2400W,Our universal ultrasonic generator is particularly suitable for continues applications such as cutting and non-woven welding. The built-in circuit provides a purer sine wave drive transducer than most generators on the market, making the heat generation less and efficiency higher. Reduce heat dissipation requirements and extend life.Working mode: automatic mode: continues mode, suitable for cleaning / cutting / non-woven welding, etc. For ultrasonic mask slicer , we introduce and suggest the auto model with continues welding only.

Features:

Automatic frequency tracking: The system automatically tracks the resonance frequency of the welding horn. Compensate for detuning caused by heat and other reasons.

Digital frequency control: The operating frequency is digitally controlled by the microcontroller.

Digital amplitude setting: This feature allows users to set precise amplitudes according to application requirements, which provides a larger range and repeatability of settings than analog systems.

The amplitude can be adjusted in a large range: 1% ~ 100% continuously adjustable, which is different from the shortcomings of traditional generators that are difficult to work with low amplitude.

High-speed micro-controller: The internal micro-controller operates at a frequency of up to 168MHz, which can accurately and timely control the working conditions. Control and sampling interval of 0.5 milliseconds: 2000 times of sampling and control for welding process per second.

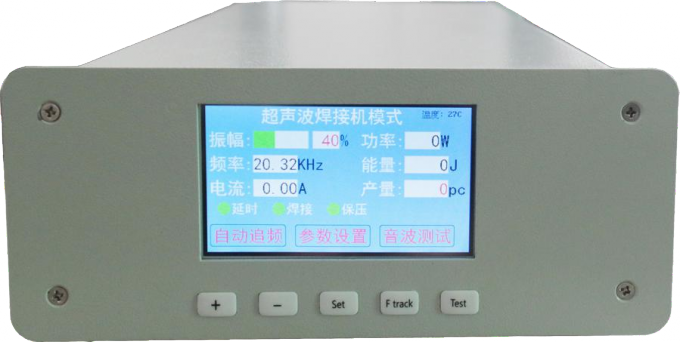

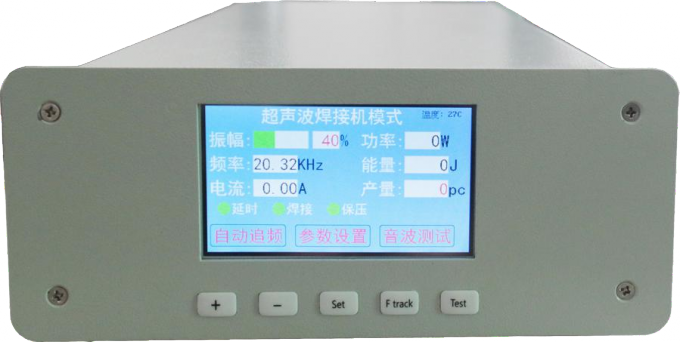

Color touch screen display: Through the color screen and touch, friendly and easy-to-use human-computer interaction is realized, and the experience is better.Coexistence of buttons and touch: common functions can provide better interaction through buttons. Among them, the buttons use silicone keys, which have a better feel.

Operating language: The user can select the applicable language in the start screen: currently only supports English and Chinese.

Slant start: Ultrasonic energy supply and welding horn start at the most suitable ascent speed to reduce the electromechanical pressure of the system.

Vibration after welding: The user can start the ultrasonic after the welding and pressure holding process is finished, and the workpiece sticking to the welding horn will be shaken off.

Welding quality monitoring: user-definable process alarm. When it is outside the range of user-defined defective products, the system will generate an alarm to remindthe user.

Diagnosis at startup: During the startup process, the main components of the system are tested.

Timing frequency search: When starting up, the system conducts frequency search every one minute to update the resonance frequency of the welding horn. This is especially effective for a welding process that can affect the temperature of the welding horn. A change in the temperature of the welding horn will cause the resonance frequency to drift.

All kinds of protection are complete: including over power consumption of the whole machine,

Inverter tube overcurrent, Inverter tube drive undervoltage, Load overvoltage,

Load overcurrent, Load overpower,

The load impedance is abnormal,

The load frequency is out of range,

Over temperature,

Overcurrent of external devices (such as solenoid valve),

The control circuit voltage is out of range.

| High Light | ultrasonic slice machine,ultrasonic medical mask spot welder | ||

|---|---|---|---|

*With best PZT8 in China

*The impedance of the transducer is less than 8 and the impedance of the transducer and welding horn is less than 40.

*5times test for ultrasonic check

*3hours Temperature rise detection

*To confirm all your transducer with horn no matching problem.

| Item | Parameter |

| Frequency | 20KHZ |

| Power | 2000W |

| Horn size | 110*20 OR 150*35mm |

| Horn material | Steel or Aluminum |

| weight | 14.5kg |

Intelligent fan control: When the temperature is low, the fan starts following the ultrasonic output. If there is no ultrasonic output within 30 seconds, the fan stops to prevent inhalation of excessive dust and improve the reliability of the device.When the high temperature exceeds 45 ° C, the fan will continue to work to cool down.When the temperature exceeds 80 ° C, the device will provide over-temperature protection and prompt on the screen.Power limitation: In order to be able to work continuously around 2000W, the actual power protection threshold of the generator is 2400W,Our universal ultrasonic generator is particularly suitable for continues applications such as cutting and non-woven welding. The built-in circuit provides a purer sine wave drive transducer than most generators on the market, making the heat generation less and efficiency higher. Reduce heat dissipation requirements and extend life.Working mode: automatic mode: continues mode, suitable for cleaning / cutting / non-woven welding, etc. For ultrasonic mask slicer , we introduce and suggest the auto model with continues welding only.

Features:

Automatic frequency tracking: The system automatically tracks the resonance frequency of the welding horn. Compensate for detuning caused by heat and other reasons.

Digital frequency control: The operating frequency is digitally controlled by the microcontroller.

Digital amplitude setting: This feature allows users to set precise amplitudes according to application requirements, which provides a larger range and repeatability of settings than analog systems.

The amplitude can be adjusted in a large range: 1% ~ 100% continuously adjustable, which is different from the shortcomings of traditional generators that are difficult to work with low amplitude.

High-speed micro-controller: The internal micro-controller operates at a frequency of up to 168MHz, which can accurately and timely control the working conditions. Control and sampling interval of 0.5 milliseconds: 2000 times of sampling and control for welding process per second.

Color touch screen display: Through the color screen and touch, friendly and easy-to-use human-computer interaction is realized, and the experience is better.Coexistence of buttons and touch: common functions can provide better interaction through buttons. Among them, the buttons use silicone keys, which have a better feel.

Operating language: The user can select the applicable language in the start screen: currently only supports English and Chinese.

Slant start: Ultrasonic energy supply and welding horn start at the most suitable ascent speed to reduce the electromechanical pressure of the system.

Vibration after welding: The user can start the ultrasonic after the welding and pressure holding process is finished, and the workpiece sticking to the welding horn will be shaken off.

Welding quality monitoring: user-definable process alarm. When it is outside the range of user-defined defective products, the system will generate an alarm to remindthe user.

Diagnosis at startup: During the startup process, the main components of the system are tested.

Timing frequency search: When starting up, the system conducts frequency search every one minute to update the resonance frequency of the welding horn. This is especially effective for a welding process that can affect the temperature of the welding horn. A change in the temperature of the welding horn will cause the resonance frequency to drift.

All kinds of protection are complete: including over power consumption of the whole machine,

Inverter tube overcurrent, Inverter tube drive undervoltage, Load overvoltage,

Load overcurrent, Load overpower,

The load impedance is abnormal,

The load frequency is out of range,

Over temperature,

Overcurrent of external devices (such as solenoid valve),

The control circuit voltage is out of range.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!