loading

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-TS20 |

| Minimum Order Quantity | 1set |

| Packaging Details | carton box |

| Payment Terms | T/T |

| Material | Rapid Steel,Titanium | Frequency | 20Khz |

|---|---|---|---|

| Power | 2000W | Power Supply | Ultrasonic Digital Generator |

| Tube End Shape | Wave Or Straight | Application | Cosmetic ,medical |

| High Light | Rapid Steel Ultrasonic Welding Equipment,2000W Ultrasonic Welding Equipment,Rapid Steel Ultrasonic Welder Machine | ||

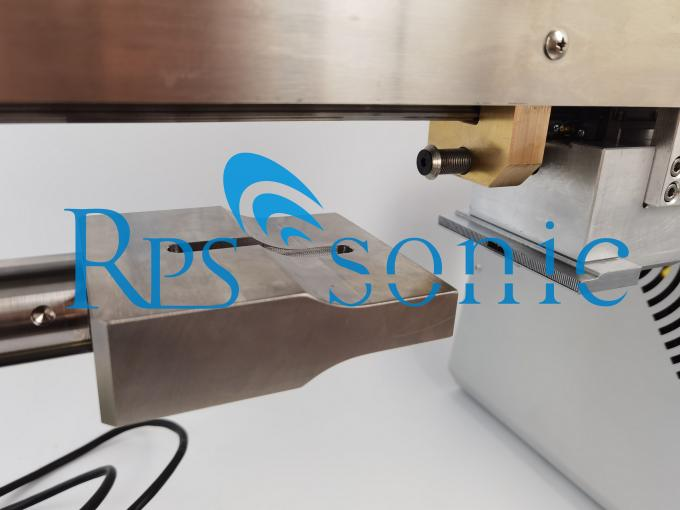

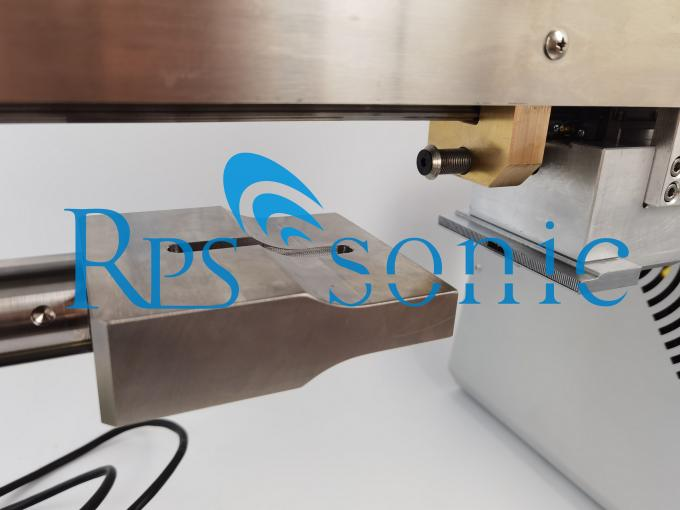

20Khz 2000W Ultrasonic soft tube welding sealing and cutting machine for wave shape or stright shape

Descripiton:

Ultrasonic soft tube end wealding sealing and cutting machine, can make 3functions all in one, because of the special designed Horn and bottom model. It makes the production much easier and helps improve the production capacity,helps saving time and cost of machine, and it can be connected to the PLC romote control.

Advantages of Digital generator to Analog generator:

1. The working frequency of the Ultrasonic digital generator is wider, and the analog generator is narrower

2. The ultrasonic digital generator works more stable and longer service life, the analog generator is easy to broken.

3. The Ultrasonic digital generator can tracking the frequency automatically, When the horn is hot or worn, the digital generator will adjust the frequency automatically , no need professional operator to adjust it, work efficiency will be much higher. The analog generator request professional operator to adjust it and easy damage.

4. The Ultrasonic digital generator with real-time monitoring and data storage functions, it can be connected to PLC equipment, but analog can’t be.

What's ultrasonic sealing?

Fast, clean and repeatable sealing of plastic or laminated collapsible squeeze tubes in a single step process. Advanced systems offering an energy-saving, environmentally-friendly, efficient process for sealing tubes across a wide range of thermoplastic materials. Systems are available with integral base for manual operation or power head actuator for automated in-line production systems.

Strength of tube seal not compromised by presence of contaminants like ink, dye, powder, emulsion, etc.

Minimal extrusion of excess plastic and/or laminate tube material.

Tube materials need not be pre-heated.

Cost-saving on-demand energy usage vs. continuous energy.

Seal strengths attainable to 100% of the parent material.

Instantaneous solidification of bonded material.

Optional product coding available (anvil side)

Parameter:

| type | PRS-TS20 |

| frequency | 20Khz |

| power | 2000W |

| power supply | AC220V |

| Application | Soft Tube end welding,sealing cutting machine |

| Tube end shape | Wave or straight, can be customized |

| Generator | Ultrasonic digital generator |

Application:

1.It's applicable to toothpaste, cosmetic, pharmaceutical, food, industry product and other soft tube welding,sealing and cutting.

2.The ultrasound output power is big enough to ensure the sealing quality of different kinds material and specifications soft tubes.

3.we can customize the horn shapes according to your requirements.

Advantages:

1.Digital generator Controlled,can tracking the frequencty automatically,stable and longer life

2.Strength of tube seal not compromised by presence of contaminants like ink,dye, powder, emulsion, etc.

3. Tube materials need not bepre-heated.Cost saving on-demand energy usage vs.continuous energy.

4. Seal strengths attainable to100% of the parent material.

5.Instantaneous solidification of bonded material.

6.Optional product&coding available

7.Welding+sealing+cutting 3functions in 1,

8.Improve production capacity , saving time and cost of machine.

| Material | Rapid Steel,Titanium | Frequency | 20Khz |

|---|---|---|---|

| Power | 2000W | Power Supply | Ultrasonic Digital Generator |

| Tube End Shape | Wave Or Straight | Application | Cosmetic ,medical |

| High Light | Rapid Steel Ultrasonic Welding Equipment,2000W Ultrasonic Welding Equipment,Rapid Steel Ultrasonic Welder Machine | ||

20Khz 2000W Ultrasonic soft tube welding sealing and cutting machine for wave shape or stright shape

Descripiton:

Ultrasonic soft tube end wealding sealing and cutting machine, can make 3functions all in one, because of the special designed Horn and bottom model. It makes the production much easier and helps improve the production capacity,helps saving time and cost of machine, and it can be connected to the PLC romote control.

Advantages of Digital generator to Analog generator:

1. The working frequency of the Ultrasonic digital generator is wider, and the analog generator is narrower

2. The ultrasonic digital generator works more stable and longer service life, the analog generator is easy to broken.

3. The Ultrasonic digital generator can tracking the frequency automatically, When the horn is hot or worn, the digital generator will adjust the frequency automatically , no need professional operator to adjust it, work efficiency will be much higher. The analog generator request professional operator to adjust it and easy damage.

4. The Ultrasonic digital generator with real-time monitoring and data storage functions, it can be connected to PLC equipment, but analog can’t be.

What's ultrasonic sealing?

Fast, clean and repeatable sealing of plastic or laminated collapsible squeeze tubes in a single step process. Advanced systems offering an energy-saving, environmentally-friendly, efficient process for sealing tubes across a wide range of thermoplastic materials. Systems are available with integral base for manual operation or power head actuator for automated in-line production systems.

Strength of tube seal not compromised by presence of contaminants like ink, dye, powder, emulsion, etc.

Minimal extrusion of excess plastic and/or laminate tube material.

Tube materials need not be pre-heated.

Cost-saving on-demand energy usage vs. continuous energy.

Seal strengths attainable to 100% of the parent material.

Instantaneous solidification of bonded material.

Optional product coding available (anvil side)

Parameter:

| type | PRS-TS20 |

| frequency | 20Khz |

| power | 2000W |

| power supply | AC220V |

| Application | Soft Tube end welding,sealing cutting machine |

| Tube end shape | Wave or straight, can be customized |

| Generator | Ultrasonic digital generator |

Application:

1.It's applicable to toothpaste, cosmetic, pharmaceutical, food, industry product and other soft tube welding,sealing and cutting.

2.The ultrasound output power is big enough to ensure the sealing quality of different kinds material and specifications soft tubes.

3.we can customize the horn shapes according to your requirements.

Advantages:

1.Digital generator Controlled,can tracking the frequencty automatically,stable and longer life

2.Strength of tube seal not compromised by presence of contaminants like ink,dye, powder, emulsion, etc.

3. Tube materials need not bepre-heated.Cost saving on-demand energy usage vs.continuous energy.

4. Seal strengths attainable to100% of the parent material.

5.Instantaneous solidification of bonded material.

6.Optional product&coding available

7.Welding+sealing+cutting 3functions in 1,

8.Improve production capacity , saving time and cost of machine.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!