loading

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-W20 |

| Minimum Order Quantity | 2 |

| Packaging Details | CARTON450*270*200MM |

| Delivery Time | 3 work days after payment |

| Payment Terms | T/T, Western Union, MoneyGram,Paypal |

| Supply Ability | 10 |

| Frequency | 20Khz | Power | 1000W |

|---|---|---|---|

| Horn | 42mm | Material | Titanium Alloy |

| Application | Ultrasonic Tetra Pak Welding | ||

| High Light | drink bottle lid ultrasonic welder,1000W Ultrasonic Welding Equipment,42mm horn Ultrasonic Welding Equipment | ||

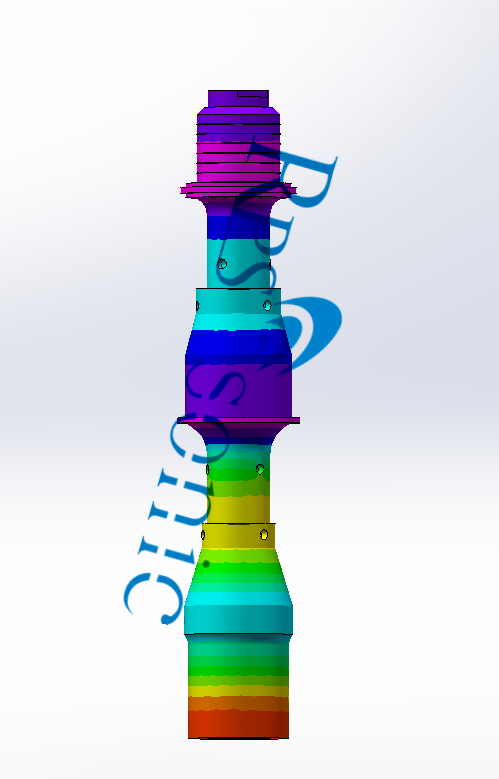

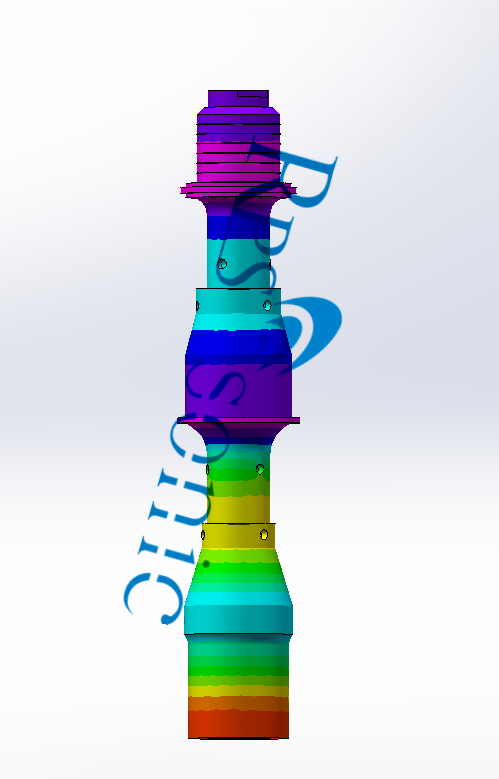

Features:This lid is used for roof type capped liquid milk and juice paper packaging machineThe principle of the ultrasonic welding machine for plastic bottle caps: The plastic bottle cap welding machine converts the current 15/20Hz electric frequency into 20KHz or 40KHz high-frequency electric energy through a transistor function device, and supplies it to the converter. The converter converts electrical energy into mechanical vibration energy for ultrasonic, and the voltage regulator is responsible for transmitting the converted mechanical energy to the welding head of the ultrasonic welding machine. The welding head is an acoustic device that directly transmits mechanical vibration energy to the product to be pressed. The vibration is transmitted to the bonding surface through the welding work piece. The vibration and friction generate heat to melt the plastic. The vibration will stop when the molten material reaches its interface. Holding the pressure for a short time can make the melt produce a strong molecular bond when the bonding surface is solidified. The entire cycle is usually completed in less than one second, but the welding strength is close to that of a connected material.

Applications:

Application of Ultrasonic Welding Machine for Plastic Bottle Caps: The ultrasonic welding machine for plastic bottle caps is mainly used for welding various round plastic bottle caps such as wine bottle caps, cosmetic caps, beverage caps, food bottle caps, etc.; generally applicable to PP, PE , ABS, AS, PC, POM, PVC and PET materials.

The ultrasonic horn for the bottle caps of ultrasonic carton packaging are generally made of titanium alloy and the size is customized. Need to know the diameter of the bottle cap for customization. In addition, the general milk beverage production line has a humid environment and is easy to touch water. Therefore, the waterproof transducer is designed to ensure safe operation in the production process.

Specifications:

| Item | Parameter |

| Model | RPS-LW20 |

| Frequency | 20Khz |

| Power | 1000W |

| Transducer | Waterproof transducer |

| Horn diameter: | inner 36.5mm/outer 42mm |

| Frequency | 20Khz | Power | 1000W |

|---|---|---|---|

| Horn | 42mm | Material | Titanium Alloy |

| Application | Ultrasonic Tetra Pak Welding | ||

| High Light | drink bottle lid ultrasonic welder,1000W Ultrasonic Welding Equipment,42mm horn Ultrasonic Welding Equipment | ||

Features:This lid is used for roof type capped liquid milk and juice paper packaging machineThe principle of the ultrasonic welding machine for plastic bottle caps: The plastic bottle cap welding machine converts the current 15/20Hz electric frequency into 20KHz or 40KHz high-frequency electric energy through a transistor function device, and supplies it to the converter. The converter converts electrical energy into mechanical vibration energy for ultrasonic, and the voltage regulator is responsible for transmitting the converted mechanical energy to the welding head of the ultrasonic welding machine. The welding head is an acoustic device that directly transmits mechanical vibration energy to the product to be pressed. The vibration is transmitted to the bonding surface through the welding work piece. The vibration and friction generate heat to melt the plastic. The vibration will stop when the molten material reaches its interface. Holding the pressure for a short time can make the melt produce a strong molecular bond when the bonding surface is solidified. The entire cycle is usually completed in less than one second, but the welding strength is close to that of a connected material.

Applications:

Application of Ultrasonic Welding Machine for Plastic Bottle Caps: The ultrasonic welding machine for plastic bottle caps is mainly used for welding various round plastic bottle caps such as wine bottle caps, cosmetic caps, beverage caps, food bottle caps, etc.; generally applicable to PP, PE , ABS, AS, PC, POM, PVC and PET materials.

The ultrasonic horn for the bottle caps of ultrasonic carton packaging are generally made of titanium alloy and the size is customized. Need to know the diameter of the bottle cap for customization. In addition, the general milk beverage production line has a humid environment and is easy to touch water. Therefore, the waterproof transducer is designed to ensure safe operation in the production process.

Specifications:

| Item | Parameter |

| Model | RPS-LW20 |

| Frequency | 20Khz |

| Power | 1000W |

| Transducer | Waterproof transducer |

| Horn diameter: | inner 36.5mm/outer 42mm |

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!