loading

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-W15 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 15Khz | Power | 2600w |

|---|---|---|---|

| Horn Material | Steel,titanium,alumium | Generator | Digital |

| Weight | 15kg | Horn Size | Customized |

| Transducer | RPS-6015-4Z | ||

| High Light | 15kHz Ultrasonic Power Supply,Titanium Horn Ultrasonic Generator,Plastic Welding Ultrasonic Power Supply | ||

15kHz High Quality Ultrasonic Power Supply For Mask Slicer Welding

15kHz Ultrasonic Welding Generator Hight Precision Generator for Ultrasonic Welding / Cutting

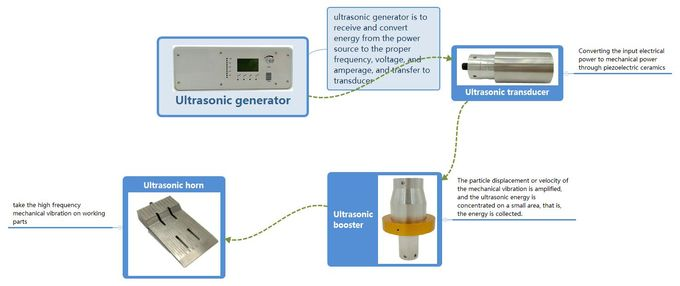

What's ultrasonic generator?

Ultrasonic generator, usually called ultrasonic power supply. Its function is to convert our mains (220V 110V or 380V, 50 or 60Hz) into a high frequency AC signal that matches the ultrasonic transducer. From the form of the amplifying circuit, a linear amplifying circuit and a switching power supply circuit can be used, and the high-power ultrasonic power source generally adopts a circuit form of a switching power supply in terms of conversion efficiency. Linear power supplies also have their own application range, which has the advantage that the circuit can be not strictly required.

Matching allows the operating frequency to change continuously and continuously. From the current situation in the ultrasound industry, ultrasonic generators are mainly divided into self-excited and separate excited power supply.

The principle of the ultrasonic generator is to first generate a signal of a specific frequency by a signal generator, which may be a sinusoidal signal or a pulse signal. This specific frequency is the frequency of the transducer, and is generally applied to ultrasonic in an ultrasonic device. The frequency is 20KHz, 25KHz, 28KHz, 33KHz, 40KHz, 60KHz,70khz, 100KHz.

Parameter:

High Frequency Ultrasonic Welding Power Supply Plastic Welding

| Item | Parameter |

| Power | 2000In max |

| Frequency range | ±1000hz |

| Operating temperature | ≤40ºC |

| Frequency | 15~40Khz |

| Amplitude adjust | 10%~100% |

| Voltage | 110V/220V |

| Circuit | Digital,separate excitation |

Our ultrasonic generator PCB can be used for non-woven bag making machine, paper cup sealing machine, three layers bag making machine, medical cloths making machine, plastic welding machine, plastic bag making machine,etc.

Application: Plastic, Toys, Electronic products, Non Woven products, Shore cover, Surgical products, lable, paper cups, mask, etc.

Generator is stat-of-the-art able operate any ultrasonic atomizer nozzle or probe including competitors from 20kHz to 600kHz and has virtually unlimited bandwidth under increased loads and frequency changes due to elevated temperatures. Power to the nozzle can be set in 1% increments or select our fine adjustment in 0.3% increments. Built inside the generator is a microprocessor and communication port with advanced electronics and unique software algorithms for effeciently driving the nozzle correctly under virtually all operating conditions. One feature is "Auto Atomization Power Adjustment" (AAPA) which can be turned on or off and is used to automatically adjust the power to the nozzle with changes in liquid flows without stalling. AAPA can be used with micro feed tubes or low flows with a high degree of control. Constant Power function freezes the power selected for the process and serves to help with coating processes increasing repeatability. All of the mentioned features are selectable from the menu and is displayed on the front panel screen. Several other functions are also available with our generator including power to the probe and bar graph. At the rear of the generator is a communication port, configurable enable/disable triggering, external power control, PLC interface and capabilities for customers who simply want to turn on/off the generator remotely with feedback or need to control all functions of the atomizer nozzle with a computer. One feature of our software tells the user if the power is too low for the liquid flow, disables power for any fault and provides this information to the user on the generator LCD display or GUI interface.

The Features of ultrasonic welding generator

Digital welding time control.

Digital stationary time control.

Digital holding time control.

Amplitude loss indication.

Overload Indication.

Robust design and can be 24 hours continuously operation.

Use high quality electronic component assembly

The advanced reliable protection circuit way greatly enhances the entire machine reliability

Frequency modulation and frequency automatic compensation

According to customers' requests to design

Our ultrasonic generator PCB advantages

1. DDS and PID high precision frequency control core.

2. Electric constant amplitude control system.

3. Welding amplitude setting range 0% - 100% by 1%.

4. Soft start, setting range 0-999MS, setprecison 1MS.

5. Three self-checking modes.

6. Pressure trigger/Time/Energy welding modes.

7. Six protections.

8. Less space, total weight 1.3KG.

| Frequency | 15Khz | Power | 2600w |

|---|---|---|---|

| Horn Material | Steel,titanium,alumium | Generator | Digital |

| Weight | 15kg | Horn Size | Customized |

| Transducer | RPS-6015-4Z | ||

| High Light | 15kHz Ultrasonic Power Supply,Titanium Horn Ultrasonic Generator,Plastic Welding Ultrasonic Power Supply | ||

15kHz High Quality Ultrasonic Power Supply For Mask Slicer Welding

15kHz Ultrasonic Welding Generator Hight Precision Generator for Ultrasonic Welding / Cutting

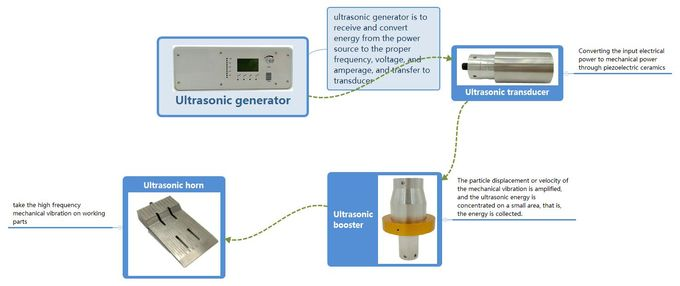

What's ultrasonic generator?

Ultrasonic generator, usually called ultrasonic power supply. Its function is to convert our mains (220V 110V or 380V, 50 or 60Hz) into a high frequency AC signal that matches the ultrasonic transducer. From the form of the amplifying circuit, a linear amplifying circuit and a switching power supply circuit can be used, and the high-power ultrasonic power source generally adopts a circuit form of a switching power supply in terms of conversion efficiency. Linear power supplies also have their own application range, which has the advantage that the circuit can be not strictly required.

Matching allows the operating frequency to change continuously and continuously. From the current situation in the ultrasound industry, ultrasonic generators are mainly divided into self-excited and separate excited power supply.

The principle of the ultrasonic generator is to first generate a signal of a specific frequency by a signal generator, which may be a sinusoidal signal or a pulse signal. This specific frequency is the frequency of the transducer, and is generally applied to ultrasonic in an ultrasonic device. The frequency is 20KHz, 25KHz, 28KHz, 33KHz, 40KHz, 60KHz,70khz, 100KHz.

Parameter:

High Frequency Ultrasonic Welding Power Supply Plastic Welding

| Item | Parameter |

| Power | 2000In max |

| Frequency range | ±1000hz |

| Operating temperature | ≤40ºC |

| Frequency | 15~40Khz |

| Amplitude adjust | 10%~100% |

| Voltage | 110V/220V |

| Circuit | Digital,separate excitation |

Our ultrasonic generator PCB can be used for non-woven bag making machine, paper cup sealing machine, three layers bag making machine, medical cloths making machine, plastic welding machine, plastic bag making machine,etc.

Application: Plastic, Toys, Electronic products, Non Woven products, Shore cover, Surgical products, lable, paper cups, mask, etc.

Generator is stat-of-the-art able operate any ultrasonic atomizer nozzle or probe including competitors from 20kHz to 600kHz and has virtually unlimited bandwidth under increased loads and frequency changes due to elevated temperatures. Power to the nozzle can be set in 1% increments or select our fine adjustment in 0.3% increments. Built inside the generator is a microprocessor and communication port with advanced electronics and unique software algorithms for effeciently driving the nozzle correctly under virtually all operating conditions. One feature is "Auto Atomization Power Adjustment" (AAPA) which can be turned on or off and is used to automatically adjust the power to the nozzle with changes in liquid flows without stalling. AAPA can be used with micro feed tubes or low flows with a high degree of control. Constant Power function freezes the power selected for the process and serves to help with coating processes increasing repeatability. All of the mentioned features are selectable from the menu and is displayed on the front panel screen. Several other functions are also available with our generator including power to the probe and bar graph. At the rear of the generator is a communication port, configurable enable/disable triggering, external power control, PLC interface and capabilities for customers who simply want to turn on/off the generator remotely with feedback or need to control all functions of the atomizer nozzle with a computer. One feature of our software tells the user if the power is too low for the liquid flow, disables power for any fault and provides this information to the user on the generator LCD display or GUI interface.

The Features of ultrasonic welding generator

Digital welding time control.

Digital stationary time control.

Digital holding time control.

Amplitude loss indication.

Overload Indication.

Robust design and can be 24 hours continuously operation.

Use high quality electronic component assembly

The advanced reliable protection circuit way greatly enhances the entire machine reliability

Frequency modulation and frequency automatic compensation

According to customers' requests to design

Our ultrasonic generator PCB advantages

1. DDS and PID high precision frequency control core.

2. Electric constant amplitude control system.

3. Welding amplitude setting range 0% - 100% by 1%.

4. Soft start, setting range 0-999MS, setprecison 1MS.

5. Three self-checking modes.

6. Pressure trigger/Time/Energy welding modes.

7. Six protections.

8. Less space, total weight 1.3KG.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!