loading

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-SI60 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Frequency | 60Khz | Power | 100w |

|---|---|---|---|

| Horn Material | Titanium | Temperature Range | 150 ~ 400 °C |

| Power Supply | 220V / 50-60 Hz | Size | 250(W) X 310(L) X 135(H) Mm |

| Iron Handle Length & Diameter | 190mm / Ø20 | ||

| High Light | 60Khz Ultrasonic Soldering Iron Equipment,Ultrasonic Soldering Iron 100W,Circuit Boards Ultrasonic Soldering Equipment | ||

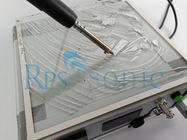

60Khz Ultrasonic Soldering Iron Equipment For Soldering To Ceramic, Aluminum, Circuit Boards, Non Metals

60Khz 100W Ultrasonic Soldering Iron For Metal ,Glass And Ceramic Soldering

60Khz 100W Ultrasonic Soldering Iron for metal soldering

Parameter

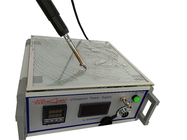

| Model No. | RPS-SI60 | |

| Ultrasonic Frequency | 60Khz | |

| Maximum Output | 100 Watt | |

| Temperature Range | 150 ~ 400 °C | |

| Power Supply | 220V / 50-60 Hz | |

| Ultrasonic Generator | Size | 250(W) x 310(L) x 135(H) mm |

| Weight | 5 Kg | |

| Feature | Ultrasonic Amplitude Adjustable | |

| Iron Handle Length & Diameter | 190mm / Ø20 | |

| Avail Soldering Matrial | ITO Glass, AL, Mo, Cu etc., | |

Description

Ultrasonic soldering is mainly used for “flux-less soldering” or “fulx free” to non metals such as glass, ceramic, and to such difficult-to-solder metals as aluminum and stainless steel. Nowaday, environmental concerns have been seen in global societies and manufacturing industries as represented by RoHS and other regulations. Ultrasonic soldering help manufacturers to reduce or eliminate the use of halogen material, which is the main chemical of flux.

Soldering conventionally involves bonding solder (tin) with a metallic substrate. Ultrasonic soldering method is an advanced way that enables solder to bond with glass or non-metallic materials. As renewable energy sources are attaining widespread use around the world, electrodes are being affixed to solar voltaic panels. Ultrasonic soldering has been adopted for this application.

Aluminum and stainless have a strong oxide layer. Even today, strong acidic flux is used to remove the oxide skin for special soldering on aluminum and other materials. However, today’s environmental regulations have driven a trend to avoid the use of highly-polluting halogen materials. On one hand, glass and aluminum are themselves oxidized materials, thus, conventional iron tip soldering principle cannot apply.

“When ultrasonic wave vibrations are applied to a liquid, small cavities are produced in bubble form due to pressure differences within the flow. This phenomenon is called cavitation. The cavities are collapsed by atmospheric pressure. A large amount of energy is generated during that 1/50,000 second. Ultrasonic soldering utilizes cavitation’s energy to enable the removal of the oxide skin. This is because it exploits this mechanism that obviates the need for flux in the soldering process.”

Starting with bonding of electrodes to glass in solar panels, there are many diverse fields in which ultrasonic soldering is used. MCUs that form the “brains” of an automobile are completely encased in aluminum to block external noise. ultrasonic soldering is used for soldering the aluminum. Recent years have seen an increase in instances of coils of aluminum wires replacing copper wires in motor coils and transmissions to reduce weight. ultrasonic soldering, with a mechanism that differs from laser and tip soldering. Its applications are expanding day by day, enabling work that had been impossible in the past.

| Frequency | 60Khz | Power | 100w |

|---|---|---|---|

| Horn Material | Titanium | Temperature Range | 150 ~ 400 °C |

| Power Supply | 220V / 50-60 Hz | Size | 250(W) X 310(L) X 135(H) Mm |

| Iron Handle Length & Diameter | 190mm / Ø20 | ||

| High Light | 60Khz Ultrasonic Soldering Iron Equipment,Ultrasonic Soldering Iron 100W,Circuit Boards Ultrasonic Soldering Equipment | ||

60Khz Ultrasonic Soldering Iron Equipment For Soldering To Ceramic, Aluminum, Circuit Boards, Non Metals

60Khz 100W Ultrasonic Soldering Iron For Metal ,Glass And Ceramic Soldering

60Khz 100W Ultrasonic Soldering Iron for metal soldering

Parameter

| Model No. | RPS-SI60 | |

| Ultrasonic Frequency | 60Khz | |

| Maximum Output | 100 Watt | |

| Temperature Range | 150 ~ 400 °C | |

| Power Supply | 220V / 50-60 Hz | |

| Ultrasonic Generator | Size | 250(W) x 310(L) x 135(H) mm |

| Weight | 5 Kg | |

| Feature | Ultrasonic Amplitude Adjustable | |

| Iron Handle Length & Diameter | 190mm / Ø20 | |

| Avail Soldering Matrial | ITO Glass, AL, Mo, Cu etc., | |

Description

Ultrasonic soldering is mainly used for “flux-less soldering” or “fulx free” to non metals such as glass, ceramic, and to such difficult-to-solder metals as aluminum and stainless steel. Nowaday, environmental concerns have been seen in global societies and manufacturing industries as represented by RoHS and other regulations. Ultrasonic soldering help manufacturers to reduce or eliminate the use of halogen material, which is the main chemical of flux.

Soldering conventionally involves bonding solder (tin) with a metallic substrate. Ultrasonic soldering method is an advanced way that enables solder to bond with glass or non-metallic materials. As renewable energy sources are attaining widespread use around the world, electrodes are being affixed to solar voltaic panels. Ultrasonic soldering has been adopted for this application.

Aluminum and stainless have a strong oxide layer. Even today, strong acidic flux is used to remove the oxide skin for special soldering on aluminum and other materials. However, today’s environmental regulations have driven a trend to avoid the use of highly-polluting halogen materials. On one hand, glass and aluminum are themselves oxidized materials, thus, conventional iron tip soldering principle cannot apply.

“When ultrasonic wave vibrations are applied to a liquid, small cavities are produced in bubble form due to pressure differences within the flow. This phenomenon is called cavitation. The cavities are collapsed by atmospheric pressure. A large amount of energy is generated during that 1/50,000 second. Ultrasonic soldering utilizes cavitation’s energy to enable the removal of the oxide skin. This is because it exploits this mechanism that obviates the need for flux in the soldering process.”

Starting with bonding of electrodes to glass in solar panels, there are many diverse fields in which ultrasonic soldering is used. MCUs that form the “brains” of an automobile are completely encased in aluminum to block external noise. ultrasonic soldering is used for soldering the aluminum. Recent years have seen an increase in instances of coils of aluminum wires replacing copper wires in motor coils and transmissions to reduce weight. ultrasonic soldering, with a mechanism that differs from laser and tip soldering. Its applications are expanding day by day, enabling work that had been impossible in the past.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!