loading

| Availability: | |

|---|---|

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

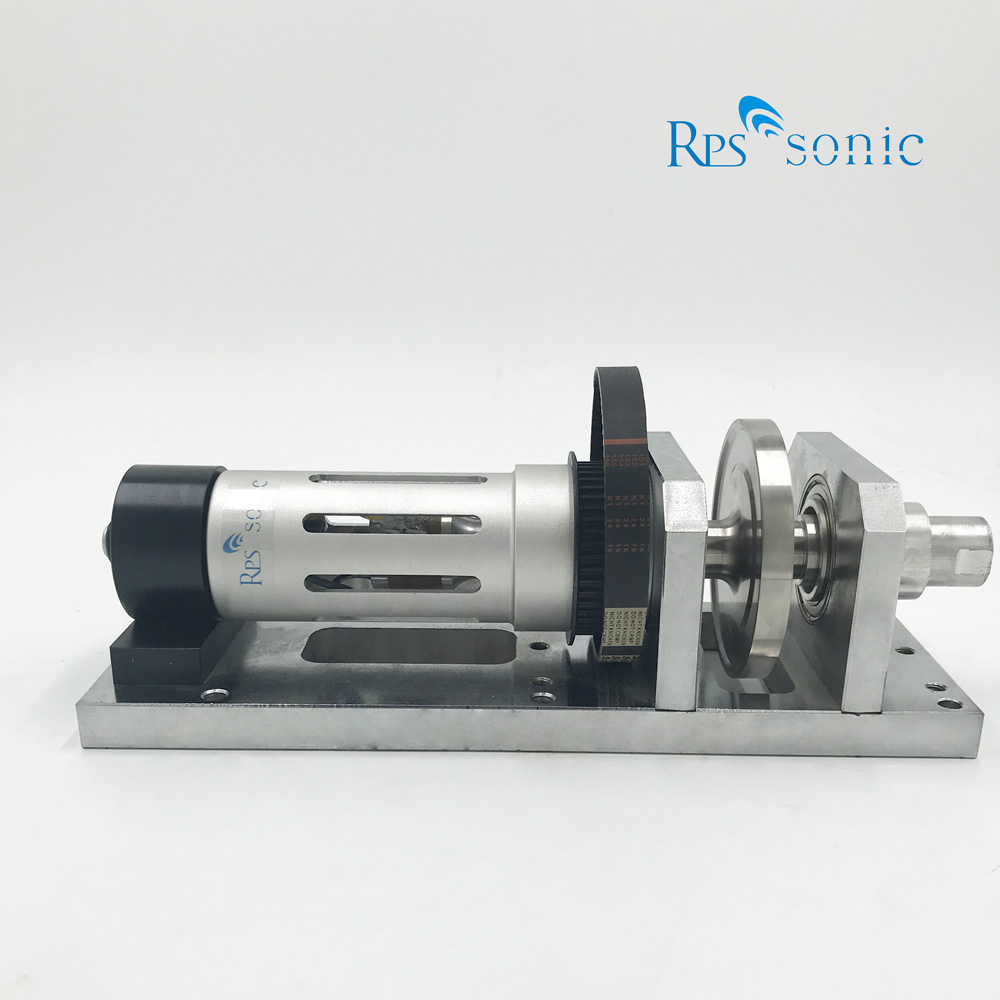

| Model Number | RPS-W35 |

| Minimum Order Quantity | 1 |

| Packaging Details | CARTON |

| Delivery Time | 3 work days after payment |

| Payment Terms | T/T, Western Union |

| Supply Ability | 100sets |

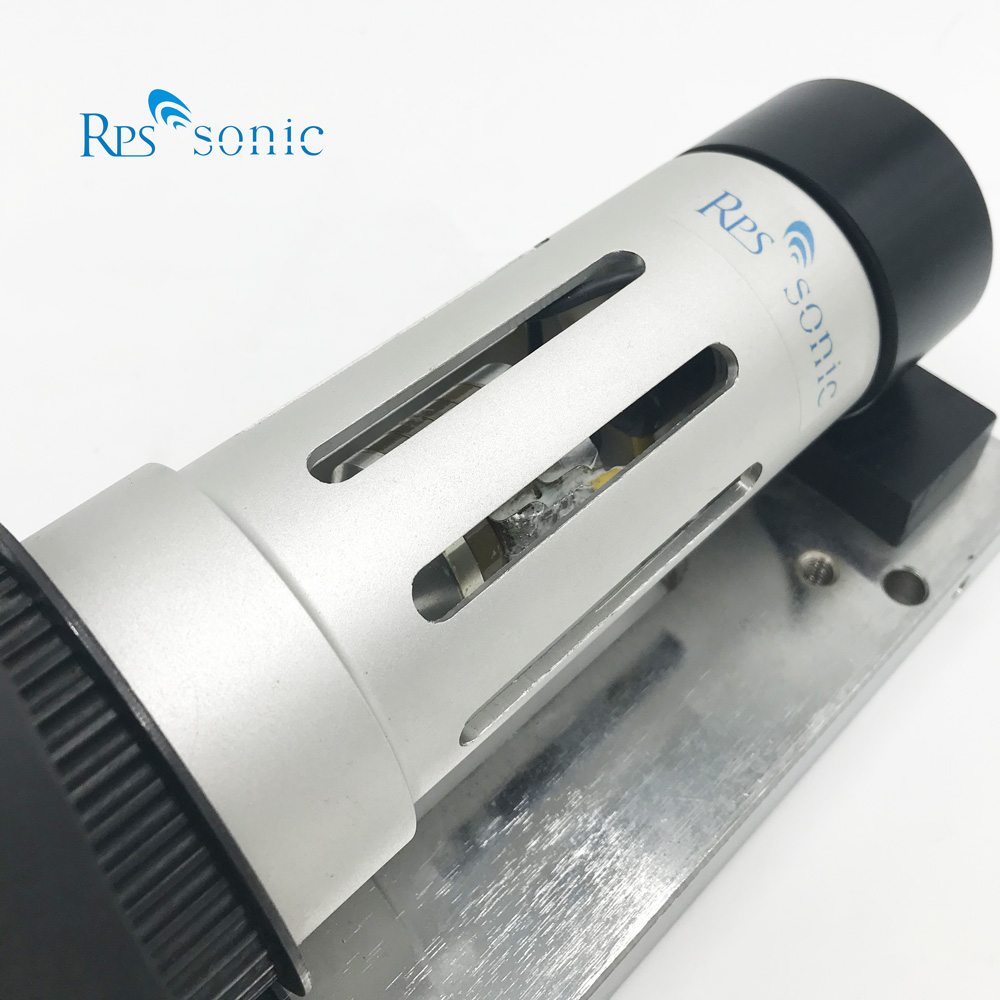

1. The ultrasonic lace machine wheel welding head is made of special alloy steel material and has undergone special heat treatment process. It has the characteristics of wear resistance and long service life. 2. The lace machine does not need to be preheated during operation. It can be processed continuously, with high speed, mass production, and corner turning. It does not produce smoke or sparks during processing and does not damage the edges of fabrics.

3. The ultrasonic lace machine sewing machine is easy to operate and easy to understand. Ordinary workers can operate the machine.

4. Use 20KHZ low-noise ultrasonic waves to prevent noise interference.

5. The ultrasonic lace machine directly sews various fabrics, and at the same time cuts edges, splits holes, and prints patterns to form the product in one go without burrs or loose edges.

6. The ultrasonic lace machine uses ultrasonic waves to directly hem, gild, and press various graphics on various materials. The power is adjusted according to different fabrics and thicknesses.

7. Color paper and gold foil paper can be added, and color printing and gilding functions can be achieved when pressurized.

8. Multiple machines can be combined into a special machine to complete products with a larger width at one time, such as quilt covers, umbrellas, etc.

Ultrasonic Vibrations:

The machine generates high-frequency ultrasonic waves (usually 20–40 kHz) via a transducer.

These vibrations are transferred to a horn (sonotrode) that contacts the fabric.

Heat Generation:

The ultrasonic vibrations cause rapid molecular friction in the synthetic fibers, generating localized heat that melts the material.

Seam Formation:

The fabric is pressed between the horn and a patterned roller or anvil.

As the materials pass through, the ultrasonic energy creates a strong, clean, and fused seam.

Textile Industry:

Seamless sewing of garments, such as lingerie, sportswear, or technical fabrics.

Hemming, cutting, and sealing fabrics for curtains, banners, and other home textiles.

Medical Industry:

Producing nonwoven items like surgical gowns, face masks, and disposable medical wear.

Packaging:

Sealing synthetic bags or pouches for food, electronics, and consumer goods.

Automotive:

Bonding or sealing interior components, such as seat covers or airbags.

1. The ultrasonic lace machine wheel welding head is made of special alloy steel material and has undergone special heat treatment process. It has the characteristics of wear resistance and long service life. 2. The lace machine does not need to be preheated during operation. It can be processed continuously, with high speed, mass production, and corner turning. It does not produce smoke or sparks during processing and does not damage the edges of fabrics.

3. The ultrasonic lace machine sewing machine is easy to operate and easy to understand. Ordinary workers can operate the machine.

4. Use 20KHZ low-noise ultrasonic waves to prevent noise interference.

5. The ultrasonic lace machine directly sews various fabrics, and at the same time cuts edges, splits holes, and prints patterns to form the product in one go without burrs or loose edges.

6. The ultrasonic lace machine uses ultrasonic waves to directly hem, gild, and press various graphics on various materials. The power is adjusted according to different fabrics and thicknesses.

7. Color paper and gold foil paper can be added, and color printing and gilding functions can be achieved when pressurized.

8. Multiple machines can be combined into a special machine to complete products with a larger width at one time, such as quilt covers, umbrellas, etc.

Ultrasonic Vibrations:

The machine generates high-frequency ultrasonic waves (usually 20–40 kHz) via a transducer.

These vibrations are transferred to a horn (sonotrode) that contacts the fabric.

Heat Generation:

The ultrasonic vibrations cause rapid molecular friction in the synthetic fibers, generating localized heat that melts the material.

Seam Formation:

The fabric is pressed between the horn and a patterned roller or anvil.

As the materials pass through, the ultrasonic energy creates a strong, clean, and fused seam.

Textile Industry:

Seamless sewing of garments, such as lingerie, sportswear, or technical fabrics.

Hemming, cutting, and sealing fabrics for curtains, banners, and other home textiles.

Medical Industry:

Producing nonwoven items like surgical gowns, face masks, and disposable medical wear.

Packaging:

Sealing synthetic bags or pouches for food, electronics, and consumer goods.

Automotive:

Bonding or sealing interior components, such as seat covers or airbags.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment