loading

| Availability: | |

|---|---|

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-2010GL |

| Minimum Order Quantity | 1set |

| Price | negotiation |

| Packaging Details | FOAM AND CARTON |

| Delivery Time | 3DAYS |

| Payment Terms | T/T, Western Union, MoneyGram |

| Supply Ability | 200 SETS PER MONTH |

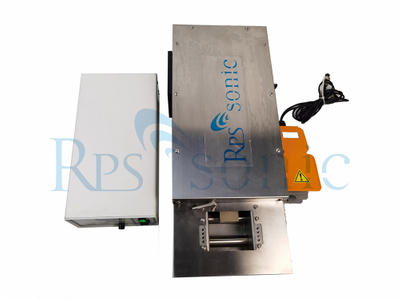

Flux free Ultrasonic Soldering Equipment Soldering Copper Stick

Ultrasonic solder pot is a key component of ultrasonic soldering equipment, which is mainly used to hold the tin block and heat it to melt it into tin liquid. The following is a detailed introduction to the ultrasonic solder pot:

Ultrasonic solder pot is usually made of high-quality stainless steel (such as 304 or 304L) or cast iron, and some high-end models even use titanium alloy materials. It is designed with a reasonable heating system and temperature control device to ensure that the tin liquid can quickly reach and maintain the required welding temperature. In the ultrasonic soldering process, the tin pot not only serves as a container for the molten tin liquid, but also transmits ultrasonic vibration energy through the ultrasonic tool head at its bottom to achieve the removal of the oxide layer on the surface of the weldment and the uniform adhesion of the tin liquid.

The system is usually used with a solder bath which has an element rating of 700W and a capacity of approx. 10 kgs. There is a solder temperature light on the front of the generator which is not in use during operation without a solder bath.

It is essential that the ultrasonic transducer remains cool, and because of this the transducer housing is fitted with a fan, and compressed air is supplied to the cooling collar on the probe. If the supplied system is used with small components heated by hot air, it is likely that the compressed air cooling will not be required.

Application

Electronic Components Soldering (No Flux)

Magnet Wire (Al or Cu) Product Soldering Motor / Transformer / Inductor / Toroidal Coil

Soldering (No Flux)

Battery Electrode Soldering

Hard-to-solder material soldering (Aluminum, Nickel, Molybdenum, Glass, Ceramic, Nonferrous metals)

Description

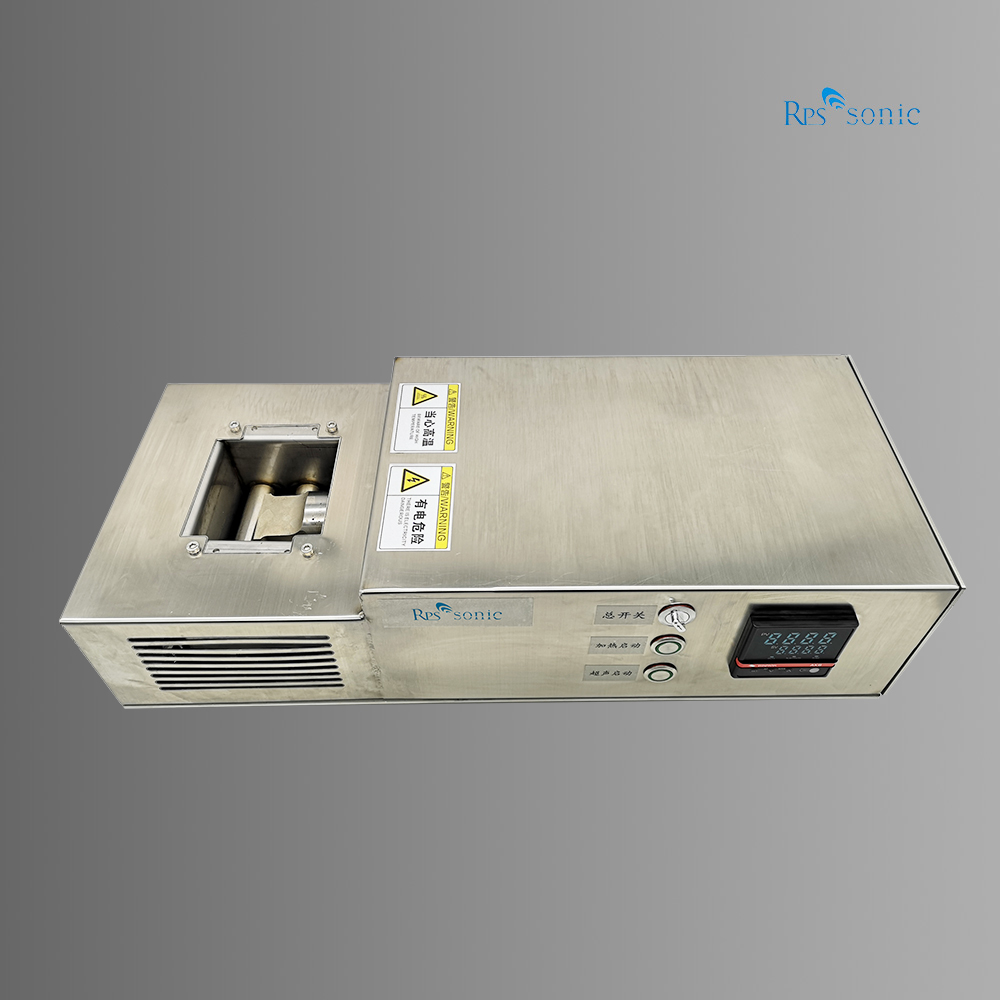

| Model No. | RPS-2010GL |

| Ultrasonic Frequency | 20 KHz ± 1 KHz |

| Maximum Output | 1000 Watt |

| Temperature Range | 200 ~ 400 °C |

| Power Supply | 220V ( Single Phase) / 50-60 Hz |

| Horn | alloy steel |

| Generator | Digital generator |

| Features | |

· Full Dgital Control · Ultrasonic Amplitude Adjustable : 10 ~ 100% · Auto Frequency Tuning : 20 kHz +/- 1 kHz · Programmable Welding Time and Energy (10 memories for welding condition) · Ultrasonic Load Meter Scale · Soldering prod Full Diucts manually · No Flux soldering | |

Electronic Component Tinning and Soldering

Component lead solderability is a major consideration when devices are to be incorporated into high reliability hardware such as that used by the military, human implants including pacemakers and defibrillators, and for aerospace applications. This is especially true in cases where the device, once installed, is not accessible for service. In these critical applications it is commonplace to "tin" component leads when they arrive at the assembly house and prior to going into storage. In some cases the component leads may again be "tinned" immediately prior to use. Ultrasonic tinning offers several advantages over conventional flux methods for high reliability lead tinning.

20 kHz vibrations from the Ultrasonic Generator via a transducer attached to the horn are transmitted to the molten solder resulting in cavitation of the molten solder. The imploding cavitation bubbles have a scrubbing effect on any submerged work piece and mechanically remove oxides. The cleaned surface is immediately coated with the solder in which it is immersed. The process does not require the use of a flux which has immediate benefits in the elimination of the fluxing operation and the procedures and equipment associated not only with its application but also with storage, residue removal etc. The soldering temperature can often be lowered simply because it is not necessary to ensure activation of a flux and this in itself reduces dross formation. The absence of a flux and its surface tension reducing properties means that there is no "wicking" of solder in the ultrasonic soldering process. Whereas this can be a disadvantage under certain conditions it is advantageous in the tinning of stranded wires and connector pins. The transducer needs to be protected in terms of temperature and the horn is therefore supplied with an air cooling collar requiring connection to a compressed air supply, in addition to an integral cooling fan.

Flux free Ultrasonic Soldering Equipment Soldering Copper Stick

Ultrasonic solder pot is a key component of ultrasonic soldering equipment, which is mainly used to hold the tin block and heat it to melt it into tin liquid. The following is a detailed introduction to the ultrasonic solder pot:

Ultrasonic solder pot is usually made of high-quality stainless steel (such as 304 or 304L) or cast iron, and some high-end models even use titanium alloy materials. It is designed with a reasonable heating system and temperature control device to ensure that the tin liquid can quickly reach and maintain the required welding temperature. In the ultrasonic soldering process, the tin pot not only serves as a container for the molten tin liquid, but also transmits ultrasonic vibration energy through the ultrasonic tool head at its bottom to achieve the removal of the oxide layer on the surface of the weldment and the uniform adhesion of the tin liquid.

The system is usually used with a solder bath which has an element rating of 700W and a capacity of approx. 10 kgs. There is a solder temperature light on the front of the generator which is not in use during operation without a solder bath.

It is essential that the ultrasonic transducer remains cool, and because of this the transducer housing is fitted with a fan, and compressed air is supplied to the cooling collar on the probe. If the supplied system is used with small components heated by hot air, it is likely that the compressed air cooling will not be required.

Application

Electronic Components Soldering (No Flux)

Magnet Wire (Al or Cu) Product Soldering Motor / Transformer / Inductor / Toroidal Coil

Soldering (No Flux)

Battery Electrode Soldering

Hard-to-solder material soldering (Aluminum, Nickel, Molybdenum, Glass, Ceramic, Nonferrous metals)

Description

| Model No. | RPS-2010GL |

| Ultrasonic Frequency | 20 KHz ± 1 KHz |

| Maximum Output | 1000 Watt |

| Temperature Range | 200 ~ 400 °C |

| Power Supply | 220V ( Single Phase) / 50-60 Hz |

| Horn | alloy steel |

| Generator | Digital generator |

| Features | |

· Full Dgital Control · Ultrasonic Amplitude Adjustable : 10 ~ 100% · Auto Frequency Tuning : 20 kHz +/- 1 kHz · Programmable Welding Time and Energy (10 memories for welding condition) · Ultrasonic Load Meter Scale · Soldering prod Full Diucts manually · No Flux soldering | |

Electronic Component Tinning and Soldering

Component lead solderability is a major consideration when devices are to be incorporated into high reliability hardware such as that used by the military, human implants including pacemakers and defibrillators, and for aerospace applications. This is especially true in cases where the device, once installed, is not accessible for service. In these critical applications it is commonplace to "tin" component leads when they arrive at the assembly house and prior to going into storage. In some cases the component leads may again be "tinned" immediately prior to use. Ultrasonic tinning offers several advantages over conventional flux methods for high reliability lead tinning.

20 kHz vibrations from the Ultrasonic Generator via a transducer attached to the horn are transmitted to the molten solder resulting in cavitation of the molten solder. The imploding cavitation bubbles have a scrubbing effect on any submerged work piece and mechanically remove oxides. The cleaned surface is immediately coated with the solder in which it is immersed. The process does not require the use of a flux which has immediate benefits in the elimination of the fluxing operation and the procedures and equipment associated not only with its application but also with storage, residue removal etc. The soldering temperature can often be lowered simply because it is not necessary to ensure activation of a flux and this in itself reduces dross formation. The absence of a flux and its surface tension reducing properties means that there is no "wicking" of solder in the ultrasonic soldering process. Whereas this can be a disadvantage under certain conditions it is advantageous in the tinning of stranded wires and connector pins. The transducer needs to be protected in terms of temperature and the horn is therefore supplied with an air cooling collar requiring connection to a compressed air supply, in addition to an integral cooling fan.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment