loading

| Availability: | |

|---|---|

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-LP28 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

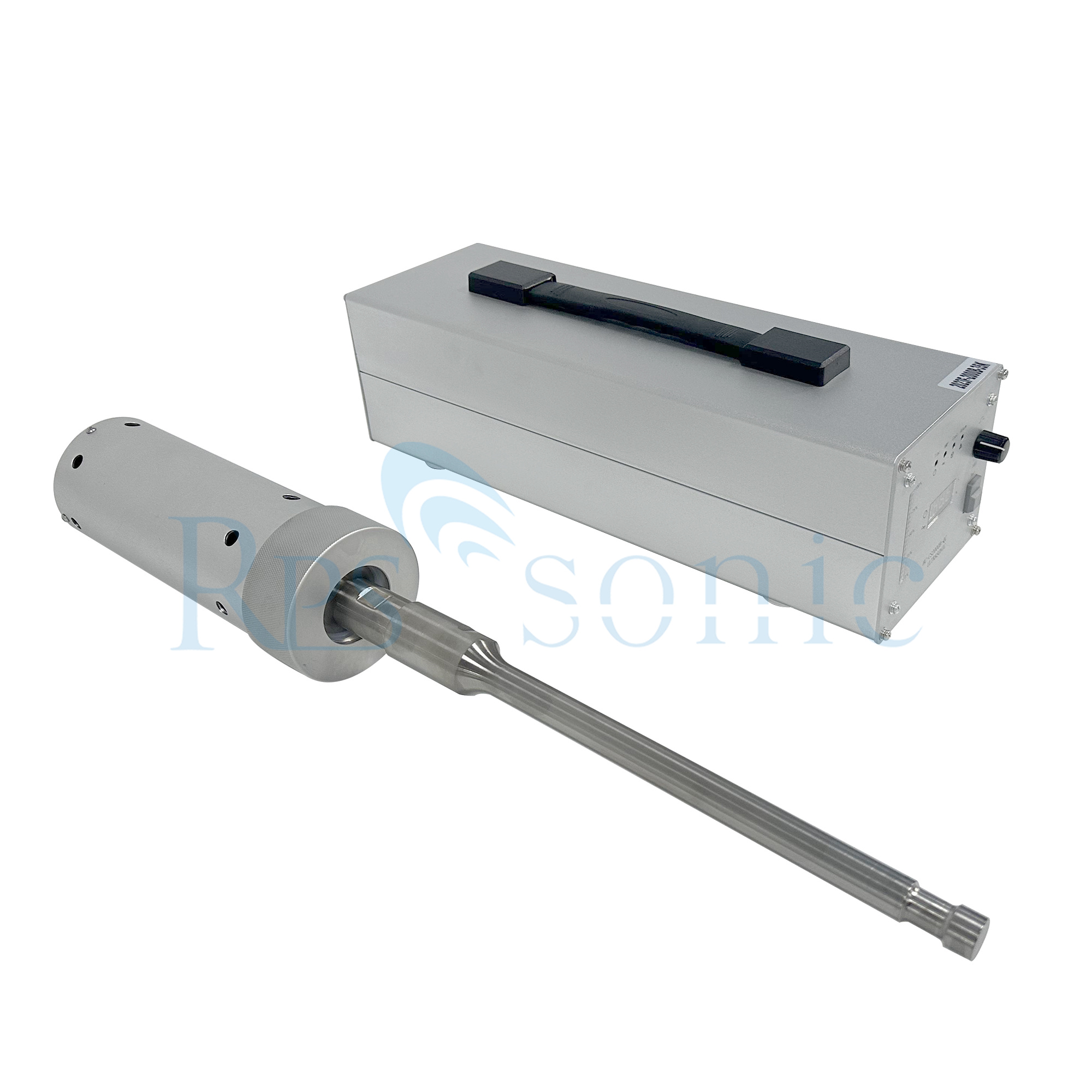

Lab 28Khz Ultrasonic nano emulsification equipment ultrasonic homogenizer with titanium horn

Parameter

| Model | SONOL20-1000 | SONOL20-500 | SONOL28-300 | SONOL40-100 |

| Frequency | 20±0.5 KHz | 20±0.5 KHz | 28±0.5 KHz | 40±0.5 KHz |

| Power | 1000 W | 500 W | 300 W | 100 W |

| Voltage | 220/110V | 220/110V | 220/110V | 220/110V |

| Temperature | 300 ℃ | 300 ℃ | 300 ℃ | 300 ℃ |

| Pressure | 35 MPa | 35 MPa | 35 MPa | 35 MPa |

| Max Capacity | 8 L/Min | 5 L/Min | 1L/Min | 0.5 L/Min |

| Tip Head Material | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Description

Ultrasonic nanoemulsification is a process that uses ultrasonic energy to produce nano-sized emulsions, which are mixtures of two immiscible liquids (like oil and water) stabilized by surfactants or emulsifiers. The ultrasonic energy creates high shear forces through cavitation, leading to the formation of stable emulsions with droplet sizes in the nanometer range (10–200 nm).

Cavitation:

Ultrasonic waves generate microbubbles in the liquid.

These bubbles rapidly expand and collapse, producing intense shear forces and turbulence.

Droplet Breakdown:

These forces disrupt larger droplets of one phase (e.g., oil) dispersed in another phase (e.g., water), reducing them to nano-sized droplets.

Stabilization:

Surfactants or stabilizers prevent the nano-sized droplets from coalescing, ensuring the stability of the emulsion.

Examples of use

– Disruption of cells, bacteria, viruses, spores, fungi or tissues (cell disruption)

– Extraction of ingredients (lysis)

– Homogenization of different substances

– Production of finest emulsions with minimum droplet size

– Dissolution of poorly and poorly soluble substances in liquids

– Production of dispersions (emulsions and suspensions)

– Catalysis and acceleration of chemical reactions

Our wide variety of devices and accessories allows us to put together the optimal equipment for the respective application:

– Selection of the SINO SONICS series (Industrial Type, Laboratory Type, Integrated Type, or Most advanced type)

– Probe type

– Direct or indirect sonication

– Flow-through sonication

– Cooling during the processing

Advantages of RPS-SONIC ultrasonic devices

• Easy and flexible handling

• Time saving

• Powerful

• Precisely controllable

• Reproducible results

• Eco-friendly and energy efficient

• Extremely durable and long lasting

• Wide product range

• Wide range of accessories for a variety of applications

• Production, service and repair in germany

• Specialist for ultrasonic technology

Lab 28Khz Ultrasonic nano emulsification equipment ultrasonic homogenizer with titanium horn

Parameter

| Model | SONOL20-1000 | SONOL20-500 | SONOL28-300 | SONOL40-100 |

| Frequency | 20±0.5 KHz | 20±0.5 KHz | 28±0.5 KHz | 40±0.5 KHz |

| Power | 1000 W | 500 W | 300 W | 100 W |

| Voltage | 220/110V | 220/110V | 220/110V | 220/110V |

| Temperature | 300 ℃ | 300 ℃ | 300 ℃ | 300 ℃ |

| Pressure | 35 MPa | 35 MPa | 35 MPa | 35 MPa |

| Max Capacity | 8 L/Min | 5 L/Min | 1L/Min | 0.5 L/Min |

| Tip Head Material | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Description

Ultrasonic nanoemulsification is a process that uses ultrasonic energy to produce nano-sized emulsions, which are mixtures of two immiscible liquids (like oil and water) stabilized by surfactants or emulsifiers. The ultrasonic energy creates high shear forces through cavitation, leading to the formation of stable emulsions with droplet sizes in the nanometer range (10–200 nm).

Cavitation:

Ultrasonic waves generate microbubbles in the liquid.

These bubbles rapidly expand and collapse, producing intense shear forces and turbulence.

Droplet Breakdown:

These forces disrupt larger droplets of one phase (e.g., oil) dispersed in another phase (e.g., water), reducing them to nano-sized droplets.

Stabilization:

Surfactants or stabilizers prevent the nano-sized droplets from coalescing, ensuring the stability of the emulsion.

Examples of use

– Disruption of cells, bacteria, viruses, spores, fungi or tissues (cell disruption)

– Extraction of ingredients (lysis)

– Homogenization of different substances

– Production of finest emulsions with minimum droplet size

– Dissolution of poorly and poorly soluble substances in liquids

– Production of dispersions (emulsions and suspensions)

– Catalysis and acceleration of chemical reactions

Our wide variety of devices and accessories allows us to put together the optimal equipment for the respective application:

– Selection of the SINO SONICS series (Industrial Type, Laboratory Type, Integrated Type, or Most advanced type)

– Probe type

– Direct or indirect sonication

– Flow-through sonication

– Cooling during the processing

Advantages of RPS-SONIC ultrasonic devices

• Easy and flexible handling

• Time saving

• Powerful

• Precisely controllable

• Reproducible results

• Eco-friendly and energy efficient

• Extremely durable and long lasting

• Wide product range

• Wide range of accessories for a variety of applications

• Production, service and repair in germany

• Specialist for ultrasonic technology

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment