loading

| Availability: | |

|---|---|

| Quantity: | |

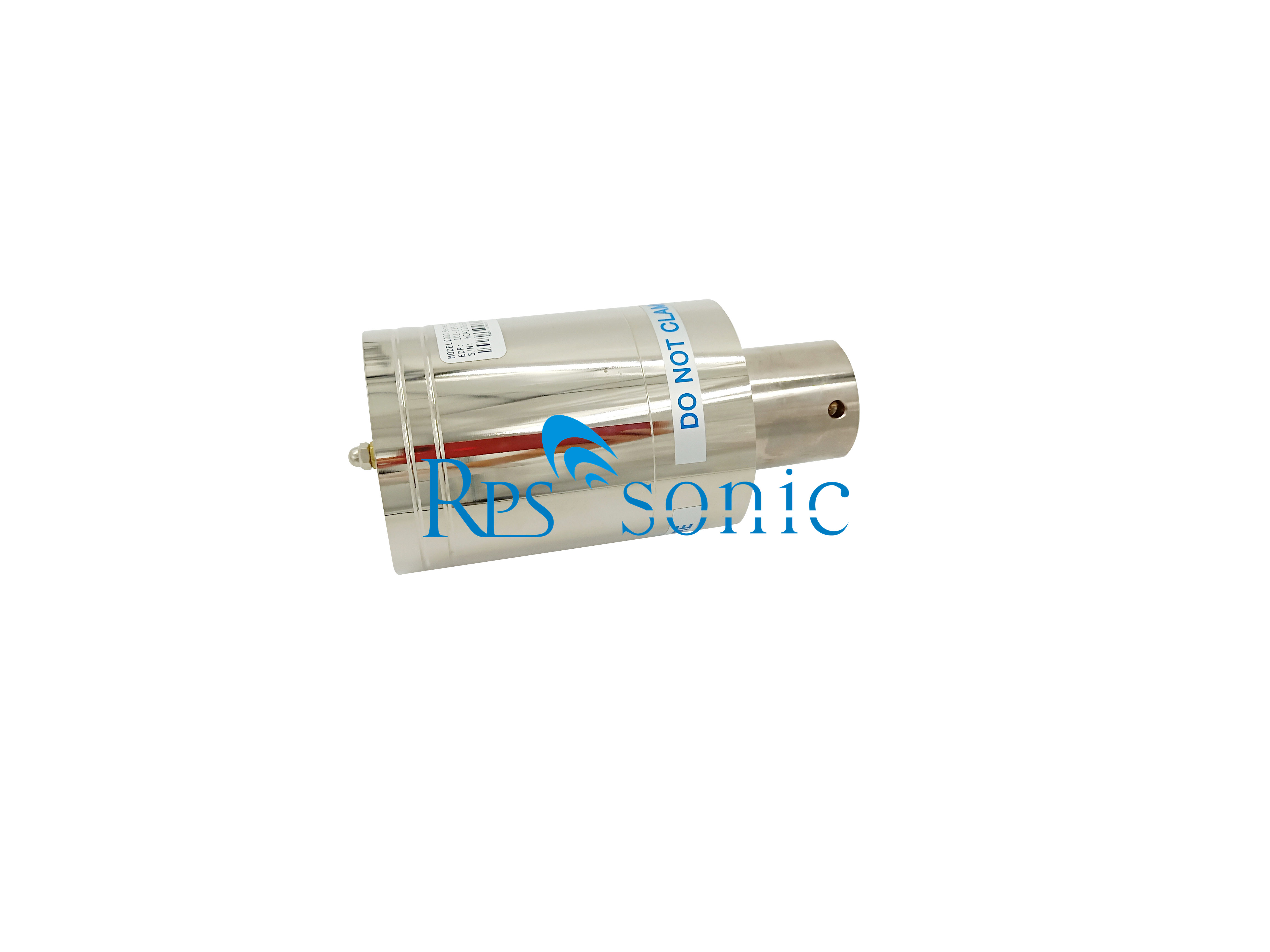

RPS-CJ20

RPS-SONIC

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-B20K |

| Minimum Order Quantity | 5 sets |

| Price | negotiation |

| Packaging Details | Foam+Carton |

| Delivery Time | 2days |

| Payment Terms | T/T, Western Union, MoneyGram |

| Supply Ability | 200 Sets/month |

| Frequency | 20Khz | Diameter | 50mm |

|---|---|---|---|

| Ceramic Chips | 4chips | Capacitance | 11500-12500 |

| Machine Model | BRANSON8800/5170 | Transducer Model | 502 |

| High Light | high frequency ultrasonic transducer,ultrasonic oscillator | ||

All the transducers, we can customize depending on your requirement.

A new high-frequency ultrasonic transducer for wire bonding has been conceived, designed, prototyped and tested. In the design phase an advanced approach was used and established. The method is based on the two basic principles of modularity and iteration. The transducer is decomposed to its elementary components. For each component an initial design is obtained with finite elements method (FEM) simulations. The simulated ultrasonic modules are then built and characterized experimentally through laser-interferometry measurements and electrical resonance spectra. The comparison of simulation results with experimental data allows the parameters of FEM models to be iteratively adjusted and optimized. The achieved FEM simulations exhibit a remarkably high-predictive potential and allow full control on the vibration behavior of the ultrasonic modules and of the whole transducer. The new transducer is fixed on the wire bonder with a flange whose special geometry was calculated by means of FEM simulations. This flange allows the converter to be attached on the wire bonder not only in longitudinal nodes but also in radial nodes of the ultrasonic field excited in the horn. This leads to a nearly complete decoupling of the transducer to the wire bonder, which has not been previously obtained. The new approach to mount ultrasonic transducers on a welding-device is of major importance not only for wire bonding but also for all high-power ultrasound applications and has been patented.

Branson Ultrasonic power converters – transducers with long life time – Upgrade and repair – reparieren or simple new quality made in China

We upgrade or repair all kinds of Branson Ultrasonic Transducers – converter – 15 kHz – 20 kHz – 30 kHz – 40 kHz.

Wir Reparieren – Serviceiren alle Arten von Bransonic Ultraschall Ultraschallwandler – Ultraschall-schwinger – Ultraschall Konverter – Wandler – 15 kHz – 20 kHz – 30 kHz – 40 kHz

We make our own design with HEX nut front (no more crack in the holes), or we do it also as the original design, both in aluminium or in Titanium.

Branson 102, 101-135-066R, Branson 103 Branson 402 101-135-014Converter – transducer, ,

Branson 108, 108-006-883, Branson 802, 101-135-034, Branson 804, Branson 803 Converter – Transuducer

Branson 502, 101-135-032 , 502 short model125-135-086 Converter – Transducer

Branson 902, Branson 922 Converter – transducer

Branson J20, 101-135-059, converter – transducer

Branson 4TH Transducer – Converter

Branson 4TJ Transducer – Converter

Branson 4TP Transducer – Converter

Branson 4TR Transducer – Converter

All others on request.

Specifications:

| MODEL | FREQUENCY(KHz) | Ca(pf) | Power(W) | Machine |

| 402 | 19.6-20.0 | 7800-8500 | 450-900 | BRANSON8400 |

| 502 | 19.6-20.0 | 11500-12500 | 2000 | BRANSON8800/5170 |

| CJ20 | 19.4-19.7 | 19000-21000 | 1100-4000 | BRANSON2000 series |

| CB35A15A | 36.5-37.5 | 3300-4000 | 800 | Rinco-35A15A |

| CV231 | 38.3-39.0 | 3500-4500 | 900 | 40K Metal welding |

| CV3510 | 36.2-37.0 | 3200-4000 | 800 | Rinco-CV3510 |

| 110-3122 | 19.6~20.0 | 12500-14000 | 2600 | Dukane heavy duty |

Advanced know how in.

Full Digital high power -Ultrasonic generators, Ultrasonic horn, ultrasonic sonotrode, sonotrode, Ultrasonic transducer, Ultrasonic booster, Ultrasonics welding, Ultrasonics welding technology, Ultrasonis cutting, Ultrasonics food slicing, Ultrasonics Food cutting, Ultrasonics Metal Welding, Ultrasonics Sealing, ultrasonics packaging, Food-cutting technologies, ultrasonic plastic processing, ultrasonics sieving, ultrasonic sealing technology, Ultrasonic Wastewater Treatment, ultrasonic bonding

Poreless, high-density piezoceramics

Mechanically very strong and stable.

High mechanical quality factor

Excellent electro-acoustic conversion efficiency

Minimal thermal dissipation and power losses

High output amplitudes

| Frequency | 20Khz | Diameter | 50mm |

|---|---|---|---|

| Ceramic Chips | 4chips | Capacitance | 11500-12500 |

| Machine Model | BRANSON8800/5170 | Transducer Model | 502 |

| High Light | high frequency ultrasonic transducer,ultrasonic oscillator | ||

All the transducers, we can customize depending on your requirement.

A new high-frequency ultrasonic transducer for wire bonding has been conceived, designed, prototyped and tested. In the design phase an advanced approach was used and established. The method is based on the two basic principles of modularity and iteration. The transducer is decomposed to its elementary components. For each component an initial design is obtained with finite elements method (FEM) simulations. The simulated ultrasonic modules are then built and characterized experimentally through laser-interferometry measurements and electrical resonance spectra. The comparison of simulation results with experimental data allows the parameters of FEM models to be iteratively adjusted and optimized. The achieved FEM simulations exhibit a remarkably high-predictive potential and allow full control on the vibration behavior of the ultrasonic modules and of the whole transducer. The new transducer is fixed on the wire bonder with a flange whose special geometry was calculated by means of FEM simulations. This flange allows the converter to be attached on the wire bonder not only in longitudinal nodes but also in radial nodes of the ultrasonic field excited in the horn. This leads to a nearly complete decoupling of the transducer to the wire bonder, which has not been previously obtained. The new approach to mount ultrasonic transducers on a welding-device is of major importance not only for wire bonding but also for all high-power ultrasound applications and has been patented.

Branson Ultrasonic power converters – transducers with long life time – Upgrade and repair – reparieren or simple new quality made in China

We upgrade or repair all kinds of Branson Ultrasonic Transducers – converter – 15 kHz – 20 kHz – 30 kHz – 40 kHz.

Wir Reparieren – Serviceiren alle Arten von Bransonic Ultraschall Ultraschallwandler – Ultraschall-schwinger – Ultraschall Konverter – Wandler – 15 kHz – 20 kHz – 30 kHz – 40 kHz

We make our own design with HEX nut front (no more crack in the holes), or we do it also as the original design, both in aluminium or in Titanium.

Branson 102, 101-135-066R, Branson 103 Branson 402 101-135-014Converter – transducer, ,

Branson 108, 108-006-883, Branson 802, 101-135-034, Branson 804, Branson 803 Converter – Transuducer

Branson 502, 101-135-032 , 502 short model125-135-086 Converter – Transducer

Branson 902, Branson 922 Converter – transducer

Branson J20, 101-135-059, converter – transducer

Branson 4TH Transducer – Converter

Branson 4TJ Transducer – Converter

Branson 4TP Transducer – Converter

Branson 4TR Transducer – Converter

All others on request.

Specifications:

| MODEL | FREQUENCY(KHz) | Ca(pf) | Power(W) | Machine |

| 402 | 19.6-20.0 | 7800-8500 | 450-900 | BRANSON8400 |

| 502 | 19.6-20.0 | 11500-12500 | 2000 | BRANSON8800/5170 |

| CJ20 | 19.4-19.7 | 19000-21000 | 1100-4000 | BRANSON2000 series |

| CB35A15A | 36.5-37.5 | 3300-4000 | 800 | Rinco-35A15A |

| CV231 | 38.3-39.0 | 3500-4500 | 900 | 40K Metal welding |

| CV3510 | 36.2-37.0 | 3200-4000 | 800 | Rinco-CV3510 |

| 110-3122 | 19.6~20.0 | 12500-14000 | 2600 | Dukane heavy duty |

Advanced know how in.

Full Digital high power -Ultrasonic generators, Ultrasonic horn, ultrasonic sonotrode, sonotrode, Ultrasonic transducer, Ultrasonic booster, Ultrasonics welding, Ultrasonics welding technology, Ultrasonis cutting, Ultrasonics food slicing, Ultrasonics Food cutting, Ultrasonics Metal Welding, Ultrasonics Sealing, ultrasonics packaging, Food-cutting technologies, ultrasonic plastic processing, ultrasonics sieving, ultrasonic sealing technology, Ultrasonic Wastewater Treatment, ultrasonic bonding

Poreless, high-density piezoceramics

Mechanically very strong and stable.

High mechanical quality factor

Excellent electro-acoustic conversion efficiency

Minimal thermal dissipation and power losses

High output amplitudes

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!