loading

| Availability: | |

|---|---|

| Quantity: | |

RPS-SONIC

| Place of Origin | China |

|---|---|

| Brand Name | RPS-Sonic |

| Certification | CE |

| Model Number | RPS-B20K |

| Minimum Order Quantity | 5 sets |

| Price | negotiation |

| Packaging Details | Foam+Carton |

| Delivery Time | 2days |

| Payment Terms | T/T, Western Union, MoneyGram |

| Supply Ability | 200 Sets/month |

| Frequency | 20Khz | Diameter | 50mm |

|---|---|---|---|

| Ceramic Chips | 4chips | Booster | Titanium |

| Power | 2000w | Amulitude | 10um |

| High Light | high frequency ultrasonic transducer,ultrasonic oscillator | ||

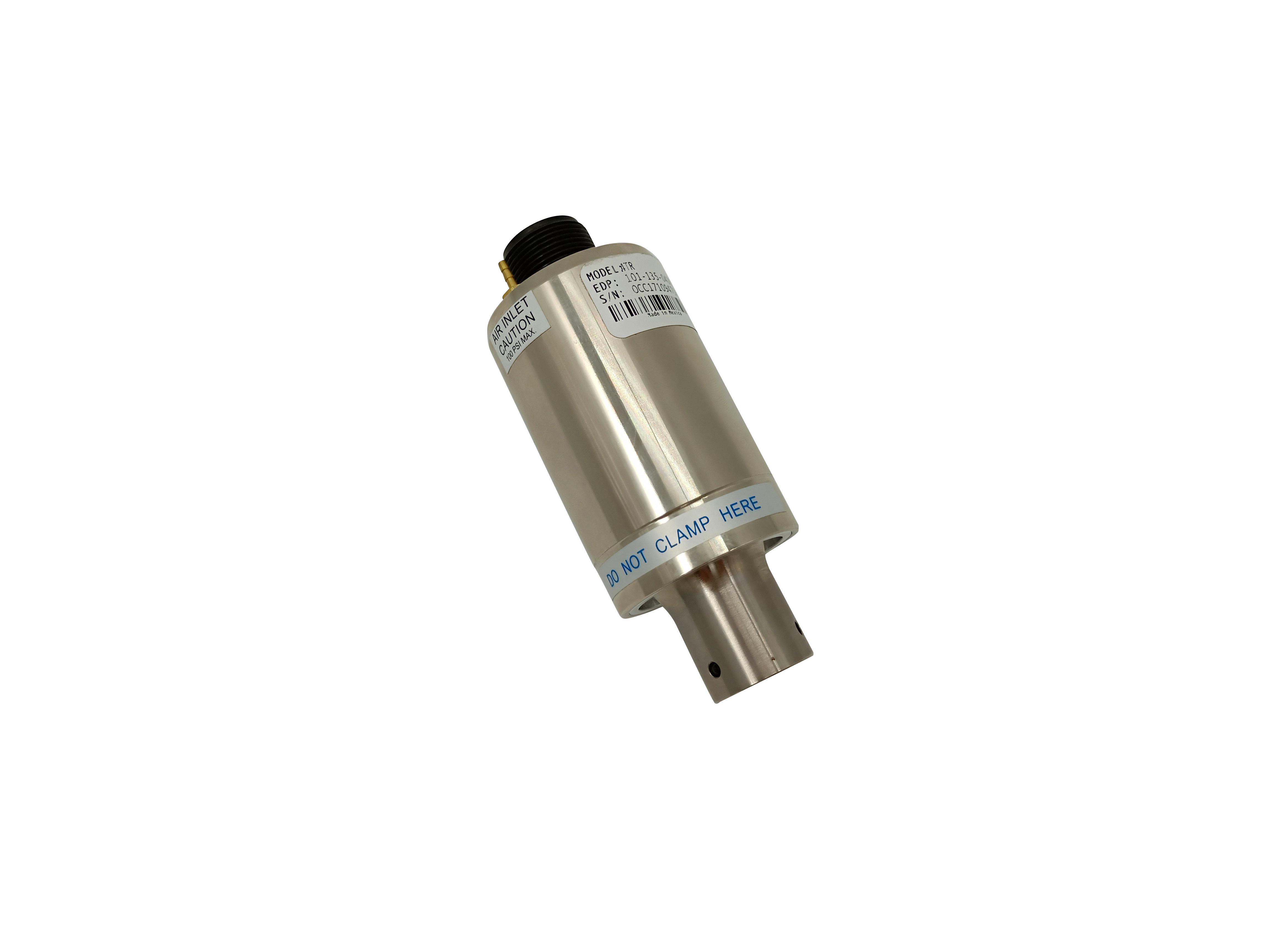

Stainless Steel Casing Ultrasonic Welding Converter For Ultrasonic Welding

All the transducers, we can customize depending on your requirement.

Branson Ultrasonic power converters – transducers with long life time – Upgrade and repair – reparieren or simple new quality made in China

We upgrade or repair all kinds of Branson Ultrasonic Transducers – converter – 15 kHz – 20 kHz – 30 kHz – 40 kHz.

Wir Reparieren – Serviceiren alle Arten von Bransonic Ultraschall Ultraschallwandler – Ultraschall-schwinger – Ultraschall Konverter – Wandler – 15 kHz – 20 kHz – 30 kHz – 40 kHz

We make our own design with HEX nut front (no more crack in the holes), or we do it also as the original design, both in aluminium or in Titanium.

Branson 102, 101-135-066R, Branson 103 Branson 402 101-135-014Converter – transducer, ,

Branson 108, 108-006-883, Branson 802, 101-135-034, Branson 804, Branson 803 Converter – Transuducer

Branson 502, 101-135-032 , 502 short model125-135-086 Converter – Transducer

Branson 902, Branson 922 Converter – transducer

Branson J20, 101-135-059, converter – transducer

Branson 4TH Transducer – Converter

Branson 4TJ Transducer – Converter

Branson 4TP Transducer – Converter

Branson 4TR Transducer – Converter

All others on request.

Specifications:

| MODEL | FREQUENCY(KHz) | Ca(pf) | Power(W) | Machine |

| 402 | 19.6-20.0 | 7800-8500 | 450-900 | BRANSON8400 |

| 502 | 19.6-20.0 | 11500-12500 | 2000 | BRANSON8800/5170 |

| CJ20 | 19.4-19.7 | 19000-21000 | 1100-4000 | BRANSON2000 series |

| CB35A15A | 36.5-37.5 | 3300-4000 | 800 | Rinco-35A15A |

| CV231 | 38.3-39.0 | 3500-4500 | 900 | 40K Metal welding |

| CV3510 | 36.2-37.0 | 3200-4000 | 800 | Rinco-CV3510 |

| 110-3122 | 19.6~20.0 | 12500-14000 | 2600 | Dukane heavy duty |

Advanced know how in.

Full Digital high power -Ultrasonic generators, Ultrasonic horn, ultrasonic sonotrode, sonotrode, Ultrasonic transducer, Ultrasonic booster, Ultrasonics welding, Ultrasonics welding technology, Ultrasonis cutting, Ultrasonics food slicing, Ultrasonics Food cutting, Ultrasonics Metal Welding, Ultrasonics Sealing, ultrasonics packaging, Food-cutting technologies, ultrasonic plastic processing, ultrasonics sieving, ultrasonic sealing technology, Ultrasonic Wastewater Treatment, ultrasonic bonding

Power range from 20 W to 6000 W

Frequency range from 20 kHz to 60 kHz

98% efficiency

Tough stainless steel casing

Low-attenuation, anti-rotation mounting

Easy to assemble without special tools

Available in various protective classes up to IP 68*

Also available for rotation applications*

Compressed air cooling connection*

Approved under ATEX guidelines for explosion-protected dust and gas areas

Approved according to UL guidelines (an organisation in Canada and the United States which certifies electrical engineering products)

Retaining ring*

Ultrasonic plastic welding transducer through the transducer head vibration generated in the tens of thousands of times per second high-frequency vibration, resulting in local temperature, the welding area of plastic welding to achieve the purpose of financial results. Ultrasonic plastic welding transducer commonly used stream of bolt clamping vertical structure, with the fixture and shaped head connected together to form the vibration plastic welding systems. I produced the plastic welding transducer with: output power mechanically stable electromechanical conversion efficiency, low heat.

Our quality of ultrasound equipment ultrasound in continuous innovation, the performance of the device has been refined and improved accuracy. Products are widely used in electrical appliances, toys, plastic, automobile, communication, medical and packaging industries.

| Frequency | 20Khz | Diameter | 50mm |

|---|---|---|---|

| Ceramic Chips | 4chips | Booster | Titanium |

| Power | 2000w | Amulitude | 10um |

| High Light | high frequency ultrasonic transducer,ultrasonic oscillator | ||

Stainless Steel Casing Ultrasonic Welding Converter For Ultrasonic Welding

All the transducers, we can customize depending on your requirement.

Branson Ultrasonic power converters – transducers with long life time – Upgrade and repair – reparieren or simple new quality made in China

We upgrade or repair all kinds of Branson Ultrasonic Transducers – converter – 15 kHz – 20 kHz – 30 kHz – 40 kHz.

Wir Reparieren – Serviceiren alle Arten von Bransonic Ultraschall Ultraschallwandler – Ultraschall-schwinger – Ultraschall Konverter – Wandler – 15 kHz – 20 kHz – 30 kHz – 40 kHz

We make our own design with HEX nut front (no more crack in the holes), or we do it also as the original design, both in aluminium or in Titanium.

Branson 102, 101-135-066R, Branson 103 Branson 402 101-135-014Converter – transducer, ,

Branson 108, 108-006-883, Branson 802, 101-135-034, Branson 804, Branson 803 Converter – Transuducer

Branson 502, 101-135-032 , 502 short model125-135-086 Converter – Transducer

Branson 902, Branson 922 Converter – transducer

Branson J20, 101-135-059, converter – transducer

Branson 4TH Transducer – Converter

Branson 4TJ Transducer – Converter

Branson 4TP Transducer – Converter

Branson 4TR Transducer – Converter

All others on request.

Specifications:

| MODEL | FREQUENCY(KHz) | Ca(pf) | Power(W) | Machine |

| 402 | 19.6-20.0 | 7800-8500 | 450-900 | BRANSON8400 |

| 502 | 19.6-20.0 | 11500-12500 | 2000 | BRANSON8800/5170 |

| CJ20 | 19.4-19.7 | 19000-21000 | 1100-4000 | BRANSON2000 series |

| CB35A15A | 36.5-37.5 | 3300-4000 | 800 | Rinco-35A15A |

| CV231 | 38.3-39.0 | 3500-4500 | 900 | 40K Metal welding |

| CV3510 | 36.2-37.0 | 3200-4000 | 800 | Rinco-CV3510 |

| 110-3122 | 19.6~20.0 | 12500-14000 | 2600 | Dukane heavy duty |

Advanced know how in.

Full Digital high power -Ultrasonic generators, Ultrasonic horn, ultrasonic sonotrode, sonotrode, Ultrasonic transducer, Ultrasonic booster, Ultrasonics welding, Ultrasonics welding technology, Ultrasonis cutting, Ultrasonics food slicing, Ultrasonics Food cutting, Ultrasonics Metal Welding, Ultrasonics Sealing, ultrasonics packaging, Food-cutting technologies, ultrasonic plastic processing, ultrasonics sieving, ultrasonic sealing technology, Ultrasonic Wastewater Treatment, ultrasonic bonding

Power range from 20 W to 6000 W

Frequency range from 20 kHz to 60 kHz

98% efficiency

Tough stainless steel casing

Low-attenuation, anti-rotation mounting

Easy to assemble without special tools

Available in various protective classes up to IP 68*

Also available for rotation applications*

Compressed air cooling connection*

Approved under ATEX guidelines for explosion-protected dust and gas areas

Approved according to UL guidelines (an organisation in Canada and the United States which certifies electrical engineering products)

Retaining ring*

Ultrasonic plastic welding transducer through the transducer head vibration generated in the tens of thousands of times per second high-frequency vibration, resulting in local temperature, the welding area of plastic welding to achieve the purpose of financial results. Ultrasonic plastic welding transducer commonly used stream of bolt clamping vertical structure, with the fixture and shaped head connected together to form the vibration plastic welding systems. I produced the plastic welding transducer with: output power mechanically stable electromechanical conversion efficiency, low heat.

Our quality of ultrasound equipment ultrasound in continuous innovation, the performance of the device has been refined and improved accuracy. Products are widely used in electrical appliances, toys, plastic, automobile, communication, medical and packaging industries.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!