loading

| Availability: | |

|---|---|

| Quantity: | |

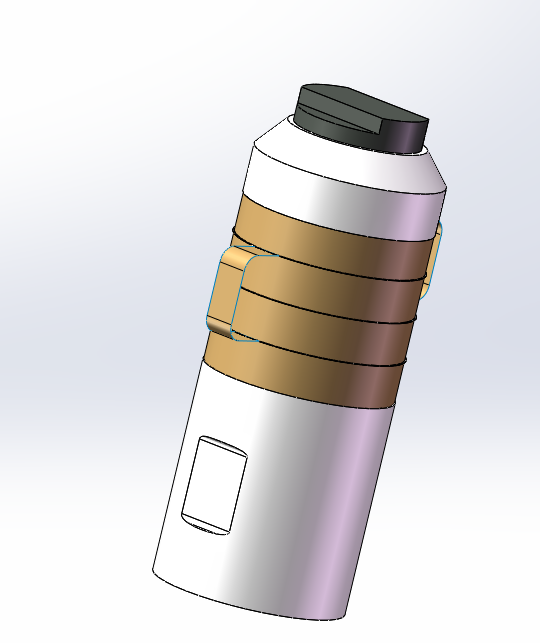

RPS-5020-4D

RPS-SONIC

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-T5020-4Z |

| Minimum Order Quantity | 5 sets |

| Price | negotiation |

| Packaging Details | Foam+Carton |

| Delivery Time | 2days |

| Payment Terms | T/T, Western Union, MoneyGram |

| Supply Ability | 200 Sets/month |

| Frequency | 20Khz | Diameter | 50mm |

|---|---|---|---|

| Name | 20 Khz Ultrasonic Transducer | Power | 1500W |

| Capacity | 11000-13000 | Resistance | <20 Ω |

| High Light | ultrasonic piezoelectric transducer,ultrasonic oscillator | ||

The basic process of ultrasonic welding can be described by the following steps:

The parts to be welded are placed in the anvil or fixture.

The horn contacts the parts to be welded.

Pressure is applied to keep the horn in contact with the welded materials and to hold them together.

The horn delivers ultrasonic vibrations to heat up the materials. The vibrations move less than a millimeter either up-and-down or side-to-side.

The materials are welded together.

The horn gets retracted and the welded materials can be removed from the anvil.

The welding times, applied pressures and temperatures are controlled by a computer or micro processor within the welding apparatus. And what actually happens during the welding process depends on the nature of the materials. In metals, the ultrasonic vibrations are delivered parallel to the plane of the materials. The frictional heat increases the temperature of the metal surfaces to about one third of the melting temperature, but does not melt the metals. Instead, the heat removes metal oxides and films from the surfaces. This allows the metal atoms to move between the two surfaces and form bonds that hold the metals together.

PARAMETER

20Khz transducer Parameter datasheet

Item No. | Connect screw (Size) | Capacitance | Input power (W) | Max. Amplitude (um) | ||

|

| Yellow | Grey | Black |

|

|

5520-4Z | M18 X 1 | 10000-11000 | 10500-11500 | 14300-20000 | 2000 | 8 |

5020-6Z | M18 X 1.5 | 18500-20000 | / | 22500-25000 | 2000 | 8 |

5020-4Z | M18 X 1.5 | 11000-13000 | 13000-15000 | 15000-17000 | 1500 | 8 |

5020-2Z | M18 X 1.5 | 6000-6500 | 6500-7000 | 8000-9000 | 800 | 6 |

4020-4Z | 1/2-20UNF | 9000-10000 | 9500-11000 | / | 900 | 6 |

4020-2Z | 1/2-20UNF | / | 4800-5500 | / | 500 | 5 |

5020-4DS | 1/2-20UNF | 11000-12000 | 12000-13500 | / | 1300 | 8 |

5020-4D | 1/2-20UNF | 11000-12000 | 12300-13500 | 13600-14600 | 1500 | 8 |

5020-6D | 1/2-20UNF | 20000-22000 | / | 25500-26500 | 2000 | 10 |

4020-6D | 1/2-20UNF | 13500-15000 | / | / | 1500 | 10 |

4020-4D | 1/2-20UNF | 8500-10500 | 10000-11000 | 10500-11500 | 900 | 8 |

3020-6D | 3/8-24UNF | 8000-9000 | / | / | 600 | 9 |

Power parameter

Frequency | Specification |

15KHz | 1800W |

2200W | |

2600W | |

3200W | |

4200W | |

20KHz | 1000W |

1500W | |

2000W | |

28KHz | 50W |

100W | |

300W | |

500W |

Description:

Ultrasonic Transducer for Welding, Drilling and Polishing High-power ultrasonic drilling machine, welding machine, polishing machine vibrator have small machinery loss, high efficiency electricity and sound transfer, big swing and less heat.

The transducer converts high-frequency electrical energy into high-frequency mechanical vibrations. And it contains several piezoelectric ceramic discs sandwiched under pressure between two metal blocks. Between each disc is a thin metal plate, which forms the electrode. When a sinusoidal electrical signal is fed to the transducer via the electrodes, the discs expand and contract, producing axial vibrations.

15Khz transducer widely used in high power welding&sealing system.Piezoelectric transducer is the electric charge that accumulates in certain solid materials in response to applied mechanical stress. It is key point of all ultrasonic equipment.The transducer decide the property of the machine.We can supply transducer, also transducer with house and booster.

To design and fabricate the transducers according to customers' requirements.

1. The piezoelectric ceramic chip adopts imported parts, and can give a strong and stable output.

2. High efficiency, high mechanical quality factor, obtaining high electric-acoustic conversion efficiency work at the resonance frequency points.

3. Large amplitude: optimization design by computer , vibration speed ratio is high .

4. Large power,Under the action of prestressed screw, the energy of the piezoelectric ceramic to get maximum play;

5. Good heat resistance, small harmonic impedance, low calorific value, using temperature range is wide.

| Frequency | 20Khz | Diameter | 50mm |

|---|---|---|---|

| Name | 20 Khz Ultrasonic Transducer | Power | 1500W |

| Capacity | 11000-13000 | Resistance | <20 Ω |

| High Light | ultrasonic piezoelectric transducer,ultrasonic oscillator | ||

The basic process of ultrasonic welding can be described by the following steps:

The parts to be welded are placed in the anvil or fixture.

The horn contacts the parts to be welded.

Pressure is applied to keep the horn in contact with the welded materials and to hold them together.

The horn delivers ultrasonic vibrations to heat up the materials. The vibrations move less than a millimeter either up-and-down or side-to-side.

The materials are welded together.

The horn gets retracted and the welded materials can be removed from the anvil.

The welding times, applied pressures and temperatures are controlled by a computer or micro processor within the welding apparatus. And what actually happens during the welding process depends on the nature of the materials. In metals, the ultrasonic vibrations are delivered parallel to the plane of the materials. The frictional heat increases the temperature of the metal surfaces to about one third of the melting temperature, but does not melt the metals. Instead, the heat removes metal oxides and films from the surfaces. This allows the metal atoms to move between the two surfaces and form bonds that hold the metals together.

PARAMETER

20Khz transducer Parameter datasheet

Item No. | Connect screw (Size) | Capacitance | Input power (W) | Max. Amplitude (um) | ||

|

| Yellow | Grey | Black |

|

|

5520-4Z | M18 X 1 | 10000-11000 | 10500-11500 | 14300-20000 | 2000 | 8 |

5020-6Z | M18 X 1.5 | 18500-20000 | / | 22500-25000 | 2000 | 8 |

5020-4Z | M18 X 1.5 | 11000-13000 | 13000-15000 | 15000-17000 | 1500 | 8 |

5020-2Z | M18 X 1.5 | 6000-6500 | 6500-7000 | 8000-9000 | 800 | 6 |

4020-4Z | 1/2-20UNF | 9000-10000 | 9500-11000 | / | 900 | 6 |

4020-2Z | 1/2-20UNF | / | 4800-5500 | / | 500 | 5 |

5020-4DS | 1/2-20UNF | 11000-12000 | 12000-13500 | / | 1300 | 8 |

5020-4D | 1/2-20UNF | 11000-12000 | 12300-13500 | 13600-14600 | 1500 | 8 |

5020-6D | 1/2-20UNF | 20000-22000 | / | 25500-26500 | 2000 | 10 |

4020-6D | 1/2-20UNF | 13500-15000 | / | / | 1500 | 10 |

4020-4D | 1/2-20UNF | 8500-10500 | 10000-11000 | 10500-11500 | 900 | 8 |

3020-6D | 3/8-24UNF | 8000-9000 | / | / | 600 | 9 |

Power parameter

Frequency | Specification |

15KHz | 1800W |

2200W | |

2600W | |

3200W | |

4200W | |

20KHz | 1000W |

1500W | |

2000W | |

28KHz | 50W |

100W | |

300W | |

500W |

Description:

Ultrasonic Transducer for Welding, Drilling and Polishing High-power ultrasonic drilling machine, welding machine, polishing machine vibrator have small machinery loss, high efficiency electricity and sound transfer, big swing and less heat.

The transducer converts high-frequency electrical energy into high-frequency mechanical vibrations. And it contains several piezoelectric ceramic discs sandwiched under pressure between two metal blocks. Between each disc is a thin metal plate, which forms the electrode. When a sinusoidal electrical signal is fed to the transducer via the electrodes, the discs expand and contract, producing axial vibrations.

15Khz transducer widely used in high power welding&sealing system.Piezoelectric transducer is the electric charge that accumulates in certain solid materials in response to applied mechanical stress. It is key point of all ultrasonic equipment.The transducer decide the property of the machine.We can supply transducer, also transducer with house and booster.

To design and fabricate the transducers according to customers' requirements.

1. The piezoelectric ceramic chip adopts imported parts, and can give a strong and stable output.

2. High efficiency, high mechanical quality factor, obtaining high electric-acoustic conversion efficiency work at the resonance frequency points.

3. Large amplitude: optimization design by computer , vibration speed ratio is high .

4. Large power,Under the action of prestressed screw, the energy of the piezoelectric ceramic to get maximum play;

5. Good heat resistance, small harmonic impedance, low calorific value, using temperature range is wide.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!