loading

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-R15 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 15Khz | Power | 2600w |

|---|---|---|---|

| Ceramic Chips | 4PCS | Material | Alumium |

| Weight | 15kg | Application | Ultrasonic Welding |

| Generator | Digital | ||

| High Light | Geogrid Ultrasonic Welding Equipment,2600w Ultrasonic Welding Tool,4PCS Ceramic Ultrasonic Welding Tool | ||

15khz 2600w Ultrasonic Welding Tool For PP PET Belt Welded Geogrid

15khz 2600w Ultrasonic Welding Machine Accessaries for PP PET Belt Welded Geogrid

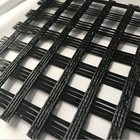

PP/PET Welded Geogrid are PP/PET belt welded geogrid, It use PP or PET as raw material, through extruding to be rib belt which with very high tensile strength,then the belts are welded by Ultrasonic welding machine to make it have high tensile strength in both Longitudinal and Transverse direction. This products mainly used for Soil stabilization, road sub-base reinforcement, aggregates confinement and improving the performance of road anti-pressure ability.

Ultrasonic welding is a high-tech which is used on welding thermoplastic products, and all kinds of thermoplastic rubber products can be welded by ultrasonic. It doesn’t need any adhesives, supplements or solvents, and it’s low energy-consuming. The machine has the advantages of simple operation, high welding strength and productivity. Therefore, ultrasonic welding technology has been used more and more widely and deeply in recent years.

Geogrid is a kind of main geosynthetics. Compared with other geosynthetics, geogrid has unique performance and efficacy. It is commonly used as reinforcement material of reinforced soil structure or composite material.

Ultrasonic welding machine is to transmit the ultrasonic wave to the processing parts through the welding head, which makes the two kinds of joint surfaces produce severe friction due to the ultrasonic effect, and the friction heat makes the plastic joint surface melt and complete the gluing. This technology has the advantages of fast speed, firm weld and so on. More importantly, it can make the product production and processing automation. Ultrasonic welding machine can be used for welding, embedding, forming, riveting, spot welding, cutting, sewing and other operations. As long as the welding head is changed, it can be used in a variety of applications.

The application of ultrasonic welding technology in plastic industry has become more and more popular in the world. Because the application of this technology can replace the flux, adhesive and other mechanical fixation methods needed in the old production, it can improve the production efficiency and quality, reduce the cost and reduce the pollution to the environment.

The plastic geogrid is characterized in that the shape of the grid hole in the geogrid is triangular, and the geogrid is formed by extrusion. The joint of the geogrid hole is provided with a circular weight reducing hole. The material of the geogrid is polypropylene. The utility model is ingenious in design and simple in use. By changing the shape of the grid hole, the gravity stretching direction of the grid is changed. In the practical engineering application, the utility model can adapt to the needs of different environments, improve the bearing capacity of the subgrade, and extend the service life of the subgrade.

The rib is a kind of high molecular plastic with high tensile strength. The joint of longitudinal and transverse ribs is welded by high frequency ultrasonic wave, which ensures the stability of product quality and the effective locking of grid grid on soil. At the same time, the strength of the grid can change the tension of the rib and adjust the number of the rib to design different models and specifications. In order to meet the needs of different projects and various technical indicators.

| Item | Parameter |

| Frequency | 15Khz |

| Power | 2600W |

| Ceramice chips | 4chips |

| Connect screw | M16 *1 |

| Frequency | 15Khz | Power | 2600w |

|---|---|---|---|

| Ceramic Chips | 4PCS | Material | Alumium |

| Weight | 15kg | Application | Ultrasonic Welding |

| Generator | Digital | ||

| High Light | Geogrid Ultrasonic Welding Equipment,2600w Ultrasonic Welding Tool,4PCS Ceramic Ultrasonic Welding Tool | ||

15khz 2600w Ultrasonic Welding Tool For PP PET Belt Welded Geogrid

15khz 2600w Ultrasonic Welding Machine Accessaries for PP PET Belt Welded Geogrid

PP/PET Welded Geogrid are PP/PET belt welded geogrid, It use PP or PET as raw material, through extruding to be rib belt which with very high tensile strength,then the belts are welded by Ultrasonic welding machine to make it have high tensile strength in both Longitudinal and Transverse direction. This products mainly used for Soil stabilization, road sub-base reinforcement, aggregates confinement and improving the performance of road anti-pressure ability.

Ultrasonic welding is a high-tech which is used on welding thermoplastic products, and all kinds of thermoplastic rubber products can be welded by ultrasonic. It doesn’t need any adhesives, supplements or solvents, and it’s low energy-consuming. The machine has the advantages of simple operation, high welding strength and productivity. Therefore, ultrasonic welding technology has been used more and more widely and deeply in recent years.

Geogrid is a kind of main geosynthetics. Compared with other geosynthetics, geogrid has unique performance and efficacy. It is commonly used as reinforcement material of reinforced soil structure or composite material.

Ultrasonic welding machine is to transmit the ultrasonic wave to the processing parts through the welding head, which makes the two kinds of joint surfaces produce severe friction due to the ultrasonic effect, and the friction heat makes the plastic joint surface melt and complete the gluing. This technology has the advantages of fast speed, firm weld and so on. More importantly, it can make the product production and processing automation. Ultrasonic welding machine can be used for welding, embedding, forming, riveting, spot welding, cutting, sewing and other operations. As long as the welding head is changed, it can be used in a variety of applications.

The application of ultrasonic welding technology in plastic industry has become more and more popular in the world. Because the application of this technology can replace the flux, adhesive and other mechanical fixation methods needed in the old production, it can improve the production efficiency and quality, reduce the cost and reduce the pollution to the environment.

The plastic geogrid is characterized in that the shape of the grid hole in the geogrid is triangular, and the geogrid is formed by extrusion. The joint of the geogrid hole is provided with a circular weight reducing hole. The material of the geogrid is polypropylene. The utility model is ingenious in design and simple in use. By changing the shape of the grid hole, the gravity stretching direction of the grid is changed. In the practical engineering application, the utility model can adapt to the needs of different environments, improve the bearing capacity of the subgrade, and extend the service life of the subgrade.

The rib is a kind of high molecular plastic with high tensile strength. The joint of longitudinal and transverse ribs is welded by high frequency ultrasonic wave, which ensures the stability of product quality and the effective locking of grid grid on soil. At the same time, the strength of the grid can change the tension of the rib and adjust the number of the rib to design different models and specifications. In order to meet the needs of different projects and various technical indicators.

| Item | Parameter |

| Frequency | 15Khz |

| Power | 2600W |

| Ceramice chips | 4chips |

| Connect screw | M16 *1 |

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

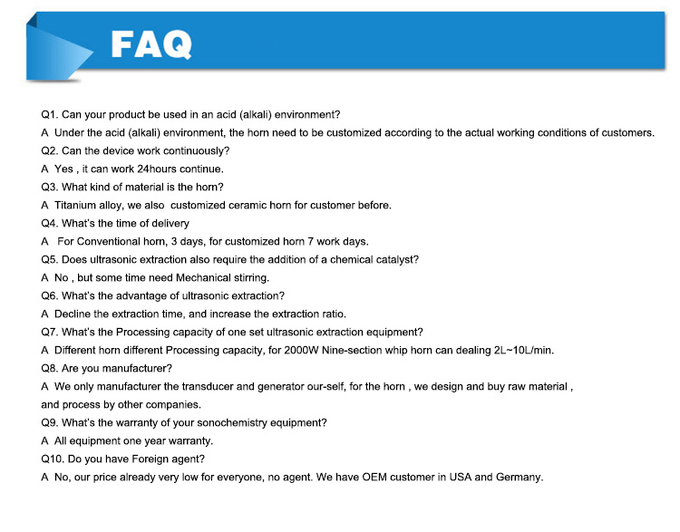

content is empty!