loading

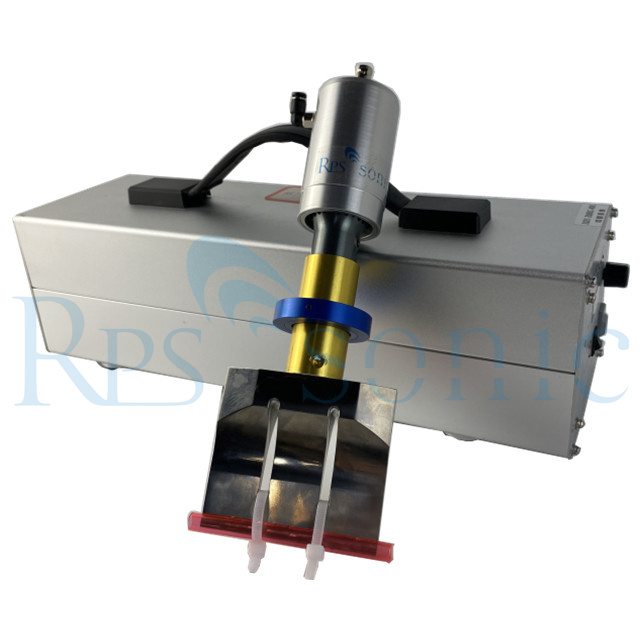

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-C40-82.5 |

| Minimum Order Quantity | 1 |

| Price | Negotiation |

| Packaging Details | CARTON |

| Delivery Time | 3 work days after payment |

| Payment Terms | T/T, Western Union,PayPal |

| Supply Ability | 100sets |

| Frequency | 40Khz | Power | 500W |

|---|---|---|---|

| Application | Rubber Cutting | Material | Titanium |

| Horn Dimension | 82.5mm | Generator | 2000CS |

| High Light | 40Khz Ultrasonic Cutting Blade,High Amplitude Ultrasonic Cutting Blade,Titanium Alloy Ultrasonic Cutting Machine | ||

Description:

The principle of the ultrasonic tire cutting machine is to convert 50/60Hz current into 20, 30 or 40kHz electric energy through an ultrasonic generator. The converted high-frequency electric energy is again converted into mechanical vibration of the same frequency through the transducer, and then the mechanical vibration is transmitted to the cutting knife through a set of amplitude modulator devices that can change the amplitude. The cutting knife transfers the received vibration energy to the cutting surface of the workpiece to be cut. In this area, the vibration energy is used to cut the rubber by activating the molecular energy of the rubber and opening the molecular chain.

Advantages of ultrasonic tire cutting machine

1 Ultrasonic tire cutting machine has high cutting precision, no deformation of rubber material, good cutting surface smoothness and good bonding performance.

2 Ultrasonic tire cutting machine is fast, efficient, pollution-free, and easy to apply to automated production.

3 Proper amplitude and feeding speed can improve cutting quality.

4 Ultrasonic tire cutting machine has high power and is more suitable for cutting the tread of luxury cars and racing cars.

5 The cutting speed depends on the angle and thickness of the tire rubber being cut.

Specificion:

| Frequency | 40Khz |

| Power | 500W 800W |

| Inupt | AC110-240V, 50/60Hz |

| Power Controller | stepping or continuous |

| Material of Cutting Head | titanium alloy |

| Machine Wight | 4 kg-16KG |

| Accessories | additional blade |

| Cooling Device | compressed air mouth can be installed. |

| Cable Length | 2M or customized |

| Foot Switch | available |

Common problems of traditional cutting:

1. Sometimes the production capacity cannot meet the required processing volume. The food to be processed is often prone to deterioration and damage;

2. When some foods are subjected to very intensive processing, they will produce broken particles, crumbs and smash that will soil the plant;

3. Food is composed of different materials and has non-uniform characteristics;

Advantages of ultrasonic cutting:

1. Ultrasonic tire cutting machine has high cutting accuracy and the rubber material is not deformed

2. Good cut surface finish and good bonding performance

3. Ultrasonic tire cutting machine is easy to apply to automated production

4. Fast speed, high efficiency, no pollution

5. Use a 20kHz cutter to cut the upper tread

6. Proper amplitude and feeding speed can improve cutting quality

7. The key factors affecting the cutting knife are the angle, rubber, shape and thickness of the knife

8. Ultrasonic tire cutting machine has high power and is more suitable for cutting the tread of luxury cars and racing cars.

9. The cutting speed depends on the angle and thickness of the cut tire rubber

10. Suitable for cutting inner lining and sidewall of semi-steel tires, radial tires, etc.

Applications:

1. Tire crown

2. Nylon

3. Steel ribbon plastic layer

4. Nylon cord;

5. Lined

6. Sidewall

7. Apex

8. Triangular circle

| Frequency | 40Khz | Power | 500W |

|---|---|---|---|

| Application | Rubber Cutting | Material | Titanium |

| Horn Dimension | 82.5mm | Generator | 2000CS |

| High Light | 40Khz Ultrasonic Cutting Blade,High Amplitude Ultrasonic Cutting Blade,Titanium Alloy Ultrasonic Cutting Machine | ||

Description:

The principle of the ultrasonic tire cutting machine is to convert 50/60Hz current into 20, 30 or 40kHz electric energy through an ultrasonic generator. The converted high-frequency electric energy is again converted into mechanical vibration of the same frequency through the transducer, and then the mechanical vibration is transmitted to the cutting knife through a set of amplitude modulator devices that can change the amplitude. The cutting knife transfers the received vibration energy to the cutting surface of the workpiece to be cut. In this area, the vibration energy is used to cut the rubber by activating the molecular energy of the rubber and opening the molecular chain.

Advantages of ultrasonic tire cutting machine

1 Ultrasonic tire cutting machine has high cutting precision, no deformation of rubber material, good cutting surface smoothness and good bonding performance.

2 Ultrasonic tire cutting machine is fast, efficient, pollution-free, and easy to apply to automated production.

3 Proper amplitude and feeding speed can improve cutting quality.

4 Ultrasonic tire cutting machine has high power and is more suitable for cutting the tread of luxury cars and racing cars.

5 The cutting speed depends on the angle and thickness of the tire rubber being cut.

Specificion:

| Frequency | 40Khz |

| Power | 500W 800W |

| Inupt | AC110-240V, 50/60Hz |

| Power Controller | stepping or continuous |

| Material of Cutting Head | titanium alloy |

| Machine Wight | 4 kg-16KG |

| Accessories | additional blade |

| Cooling Device | compressed air mouth can be installed. |

| Cable Length | 2M or customized |

| Foot Switch | available |

Common problems of traditional cutting:

1. Sometimes the production capacity cannot meet the required processing volume. The food to be processed is often prone to deterioration and damage;

2. When some foods are subjected to very intensive processing, they will produce broken particles, crumbs and smash that will soil the plant;

3. Food is composed of different materials and has non-uniform characteristics;

Advantages of ultrasonic cutting:

1. Ultrasonic tire cutting machine has high cutting accuracy and the rubber material is not deformed

2. Good cut surface finish and good bonding performance

3. Ultrasonic tire cutting machine is easy to apply to automated production

4. Fast speed, high efficiency, no pollution

5. Use a 20kHz cutter to cut the upper tread

6. Proper amplitude and feeding speed can improve cutting quality

7. The key factors affecting the cutting knife are the angle, rubber, shape and thickness of the knife

8. Ultrasonic tire cutting machine has high power and is more suitable for cutting the tread of luxury cars and racing cars.

9. The cutting speed depends on the angle and thickness of the cut tire rubber

10. Suitable for cutting inner lining and sidewall of semi-steel tires, radial tires, etc.

Applications:

1. Tire crown

2. Nylon

3. Steel ribbon plastic layer

4. Nylon cord;

5. Lined

6. Sidewall

7. Apex

8. Triangular circle

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!