loading

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-W35 |

| Minimum Order Quantity | 1set |

| Price | $6500/set |

| Packaging Details | carton box |

| Payment Terms | T/T |

| Supply Ability | 200pcs |

| Horn Material | Titanium,Rapid Steel | Frequency | 35Khz |

|---|---|---|---|

| Power | 800W | Welding Horn | Rotary Horn |

| Welding Type | Continues Working | ||

| High Light | 800 Watt Ultrasonic Sewing Machine,Rapid Steel Horn Ultrasonic Sewing Machine,Rotary Horn Ultrasonic Sealing Machine | ||

Ultrasonics is a clean and efficient method of joining or slitting synthetic materials.While the initial investment is much more, the long term benefits more than pay for itself.

Ultrasonic bonding uses high frequency sound to generate localized heat through vibration and causes thermoplastic fibers to bond together. Suppliers in the industry say the technology offers several advantages.

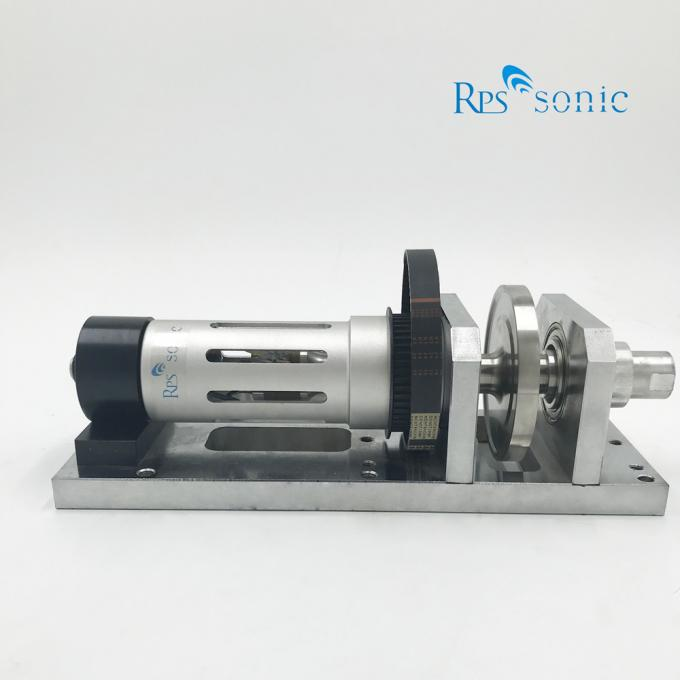

A rotary ultrasonic assembly mounted in a bearing housing that can be mounted in any orientation. It is available in 20, 35 kHz with bond widths of up to15MM. The bonder is intended for machinery manufacturers and experienced end users who desire to develop their own actuation and tooling solutions. Ultrasonic Sewing Machines operate like a traditional rotary sewing machine but produce soft, smooth seams that are impervious to moisture or fluids.

| Item | Parameter |

| Frequency | 35Khz |

| Power | 800W |

| Ceramice chips | 4chips |

| Speed | 20m/min in max |

| Welding width | 15mm in max |

| Welding horn | 35Khz rotary horn |

| Welding type | Continues welding |

Rps-sonic supply high power rotary ultrasonic systems to the packaging, hygiene and specialty converting industries.

Within the hygiene industry, Ultrasonic is used for adult and baby diapers/pant, surgical wrap, and medical face mask products for bonding, attachment, embossing and lamination of thermoplastic materials. The company has engineered solutions for feature attachment, core bonding, acquisition layers and backsheets.

Rps-sonic is also capable and willing to develop comprehensive and customized ultrasonic processing solutions that consider key parameters such as horn metallurgy, acoustic designs and geometries, component fabrication and system engineering in order to meet the processing needs of the customer.

Kindly check the AMPLITUDE REFERENCE GUIDE for ULTRASONIC WELDING (in Microns (um)) table in the next page, you will find suit frequency for your application.

| Horn Material | Titanium,Rapid Steel | Frequency | 35Khz |

|---|---|---|---|

| Power | 800W | Welding Horn | Rotary Horn |

| Welding Type | Continues Working | ||

| High Light | 800 Watt Ultrasonic Sewing Machine,Rapid Steel Horn Ultrasonic Sewing Machine,Rotary Horn Ultrasonic Sealing Machine | ||

Ultrasonics is a clean and efficient method of joining or slitting synthetic materials.While the initial investment is much more, the long term benefits more than pay for itself.

Ultrasonic bonding uses high frequency sound to generate localized heat through vibration and causes thermoplastic fibers to bond together. Suppliers in the industry say the technology offers several advantages.

A rotary ultrasonic assembly mounted in a bearing housing that can be mounted in any orientation. It is available in 20, 35 kHz with bond widths of up to15MM. The bonder is intended for machinery manufacturers and experienced end users who desire to develop their own actuation and tooling solutions. Ultrasonic Sewing Machines operate like a traditional rotary sewing machine but produce soft, smooth seams that are impervious to moisture or fluids.

| Item | Parameter |

| Frequency | 35Khz |

| Power | 800W |

| Ceramice chips | 4chips |

| Speed | 20m/min in max |

| Welding width | 15mm in max |

| Welding horn | 35Khz rotary horn |

| Welding type | Continues welding |

Rps-sonic supply high power rotary ultrasonic systems to the packaging, hygiene and specialty converting industries.

Within the hygiene industry, Ultrasonic is used for adult and baby diapers/pant, surgical wrap, and medical face mask products for bonding, attachment, embossing and lamination of thermoplastic materials. The company has engineered solutions for feature attachment, core bonding, acquisition layers and backsheets.

Rps-sonic is also capable and willing to develop comprehensive and customized ultrasonic processing solutions that consider key parameters such as horn metallurgy, acoustic designs and geometries, component fabrication and system engineering in order to meet the processing needs of the customer.

Kindly check the AMPLITUDE REFERENCE GUIDE for ULTRASONIC WELDING (in Microns (um)) table in the next page, you will find suit frequency for your application.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!