loading

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-C35 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 35Khz | Power | 500w |

|---|---|---|---|

| Horn Material | Titanium | Generator | Digital |

| Voltage | 220/110V | Application | Ultrasonic Fabric Cutter |

| Weight | 6kg | Warranty | One Year |

| High Light | Integrated Ultrasonic Cutting Knife,35 KHz Ultrasonic Cutting Knife,Titanium Handheld Ultrasonic Knife | ||

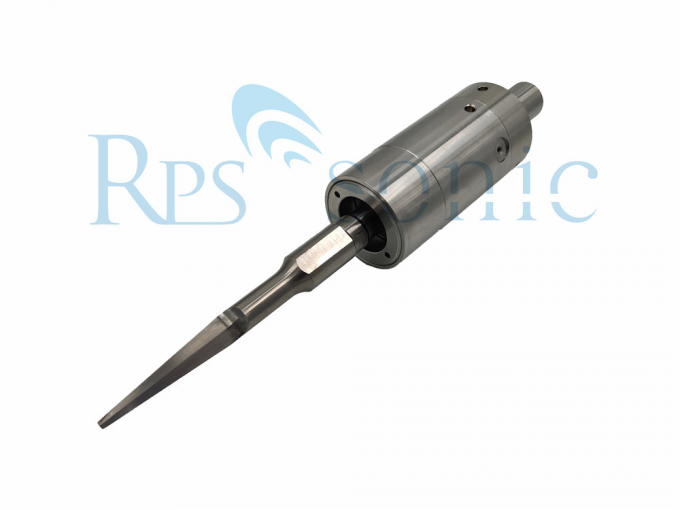

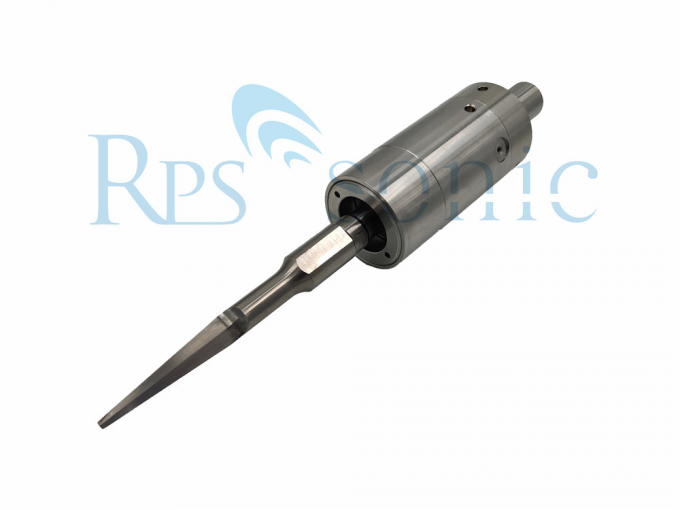

Integrated 35kHz Ultrasonic Cutting Knife For Cotton Cashmere Coat

35kHz Ultrasonic Integrated Cutting Knife for Cotton/Cashmere Coat Cutting

Parameter

|

Description

The main function of the ultrasonic cutting process is to split the connected parts. High-frequency vibration per second can reduce the pressure on the object to be cut, so that a neat and clean cutting surface can be formed. Ultrasonic cutting knives can be used in the food industry as well as solid materials such as rubber, foam and artificial leather.

Every object has its own special frequency, through which the object is stable and easy to oscillate. By adding an external force corresponding to this special frequency, even a small force can get a large vibration. This phenomenon is called resonance. Use resonance technology to make the cutting edge produce greater vibration.

The ultrasonic cutting knife is composed of a "transducer" that generates vibration and an "ultrasonic generator" that drives the transducer. The piezoelectric element is contained in the transducer. By applying an alternating voltage with the characteristic frequency* of the transducer to the piezoelectric element from the generator, the entire vibrator including the cutter blade resonates. The sensor is equipped with a feedback control system to transmit the frequency or amplitude deviation information caused by the cutting load to the generator. The feedback control system can keep the blade's resonance state and amplitude stable, so that the tool can always cut materials quickly and cleanly.

The transducer features compact size, but powerful performance thanks to the high frequency drive, thereby ensuring sharp cutting. The user-friendly design of shape enables to fully utilize the robot’s operation area. A forced air-cooling system and extended continuous use have been realized by featuring the air inlet.

The oscillator with a maximum power output of 500 W enabled powerful cutting of difficult-to-cut and extra-tough work pieces. Abrasion resistant carbide blade with 1 mm thickness can be used. Exchanging signals for on/off, emergency stop, change of output level, and other features with automated machinery or industrial robots is, of course, possible.

Application material

| plate, sheet, film, and laminated material |

|---|---|

|

| boron, Kevlar, polyethylene fibers, etc |

|

| polyethylene fibe and glass fiber |

|

| vulcanized latex, non-vulcanized latex, sheeting material, and tube |

Advantages

*The amplitude of the cutter tool is greatly im-

proved conlpared to the normal model, Increase cutter tool sharpness.

*Edge -cut with an edge seal to make processed products without burrs.

*The processing range can be used to cut the three- dimensional shape part and open the hole. *Suitable for automata. robot arms. plotters etc. *Can be used for thermoplastic processing.

Features

| Frequency | 35Khz | Power | 500w |

|---|---|---|---|

| Horn Material | Titanium | Generator | Digital |

| Voltage | 220/110V | Application | Ultrasonic Fabric Cutter |

| Weight | 6kg | Warranty | One Year |

| High Light | Integrated Ultrasonic Cutting Knife,35 KHz Ultrasonic Cutting Knife,Titanium Handheld Ultrasonic Knife | ||

Integrated 35kHz Ultrasonic Cutting Knife For Cotton Cashmere Coat

35kHz Ultrasonic Integrated Cutting Knife for Cotton/Cashmere Coat Cutting

Parameter

|

Description

The main function of the ultrasonic cutting process is to split the connected parts. High-frequency vibration per second can reduce the pressure on the object to be cut, so that a neat and clean cutting surface can be formed. Ultrasonic cutting knives can be used in the food industry as well as solid materials such as rubber, foam and artificial leather.

Every object has its own special frequency, through which the object is stable and easy to oscillate. By adding an external force corresponding to this special frequency, even a small force can get a large vibration. This phenomenon is called resonance. Use resonance technology to make the cutting edge produce greater vibration.

The ultrasonic cutting knife is composed of a "transducer" that generates vibration and an "ultrasonic generator" that drives the transducer. The piezoelectric element is contained in the transducer. By applying an alternating voltage with the characteristic frequency* of the transducer to the piezoelectric element from the generator, the entire vibrator including the cutter blade resonates. The sensor is equipped with a feedback control system to transmit the frequency or amplitude deviation information caused by the cutting load to the generator. The feedback control system can keep the blade's resonance state and amplitude stable, so that the tool can always cut materials quickly and cleanly.

The transducer features compact size, but powerful performance thanks to the high frequency drive, thereby ensuring sharp cutting. The user-friendly design of shape enables to fully utilize the robot’s operation area. A forced air-cooling system and extended continuous use have been realized by featuring the air inlet.

The oscillator with a maximum power output of 500 W enabled powerful cutting of difficult-to-cut and extra-tough work pieces. Abrasion resistant carbide blade with 1 mm thickness can be used. Exchanging signals for on/off, emergency stop, change of output level, and other features with automated machinery or industrial robots is, of course, possible.

Application material

| plate, sheet, film, and laminated material |

|---|---|

|

| boron, Kevlar, polyethylene fibers, etc |

|

| polyethylene fibe and glass fiber |

|

| vulcanized latex, non-vulcanized latex, sheeting material, and tube |

Advantages

*The amplitude of the cutter tool is greatly im-

proved conlpared to the normal model, Increase cutter tool sharpness.

*Edge -cut with an edge seal to make processed products without burrs.

*The processing range can be used to cut the three- dimensional shape part and open the hole. *Suitable for automata. robot arms. plotters etc. *Can be used for thermoplastic processing.

Features

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!