loading

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-C305 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 20Khz | Power | 1000w |

|---|---|---|---|

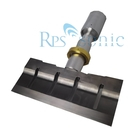

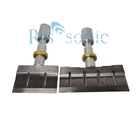

| Horn Material | Titanium | Blade Size | 305mm |

| Generator | Digital | Voltage | 220/110V |

| Application | Ultrasonic Food Cutter | Weight | 15kg |

| High Light | 20Khz Ultrasonic Cutting Machine,Titanium Blade Ultrasonic Cutting Machine,1000w Ultrasonic Cake Cutting Machine | ||

Parameter

| Machine | Ultrasonic cake Cutter |

| Frequency(KHz) | 20Khz |

| Power | 1000 W |

| Cutting Blade / Horn | Titanium |

| Voltage(V) | 220V |

| The width of blade | depend on your requirement |

| Cutting thickness | 86mm in max |

| Horn amplitude | 10-40μm |

| Equipment weight | 8KG |

Introduction

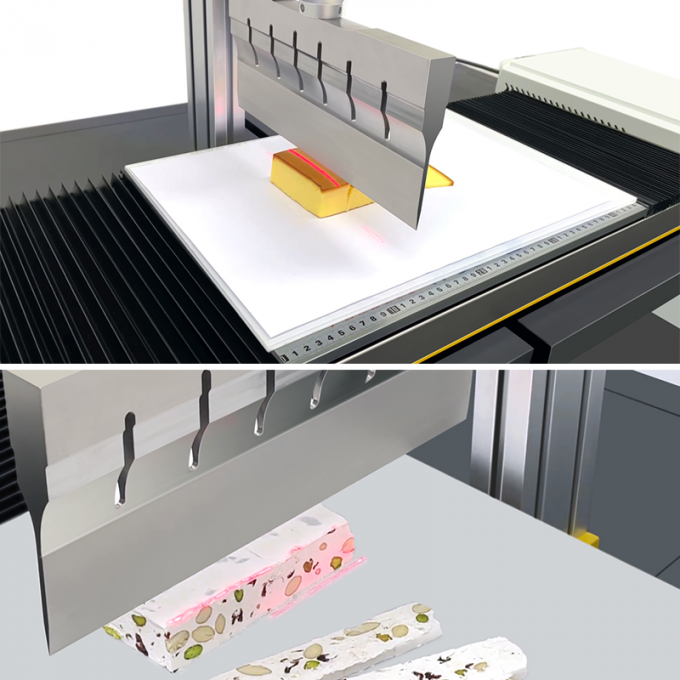

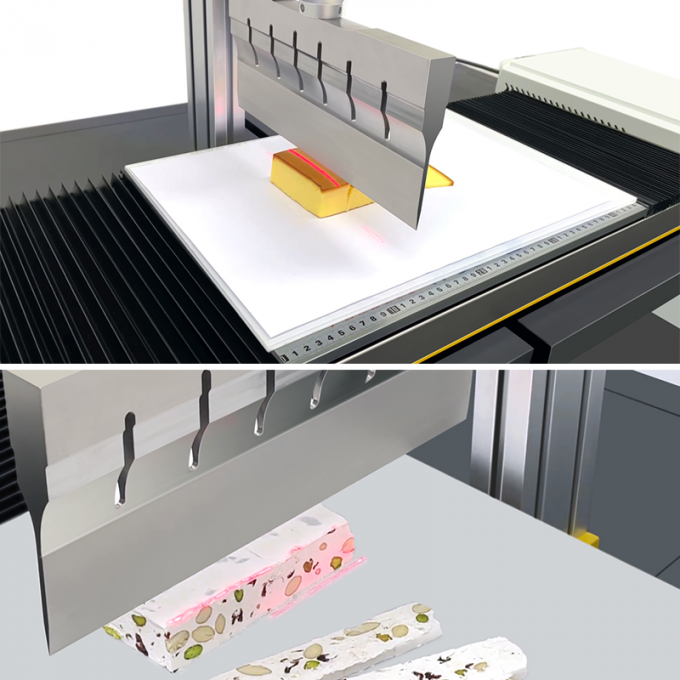

RPS-SONIC offers a complete line of specialized equipment and components for ultrasonic food cutting. Compared to conventional cutters, ultrasonic food cutters are more sanitary, with less down time, better cost-effectiveness and increased consistency at the cutting surface where the blades stay sharp longer.

Cutting tools are manufactured in-house by a precision wire EDM process that reduces stress for longer life. RPS-SONIC provides full customization of OEM components, kits and knife horns. Typical applications include cheese cutting; cake and dessert product cutting; confectionary product cutting; meat cutting; sandwich and wrap cutting.

How ultrasonic cutting system works

Ultrasonic food utting is a process uilizing knives that vibrate at high frequency. Applying ultrasonic vibration to a cutting tool creates a nearly frictionless cutting surface which provides many benefits. This low friction cutting surface can slice a multitude of food products cleanly and without smearing. Very thin slices are also possible due to the reduced resistance. Foods containing items such as vegetables, meats, nuts, berries and fruits can be cut without

deformation or displacement of the internal product. The low friction condition also reduces the tendency of products like nougat and other soft candies from sticking to the cutting tools,

resulting in more consistent cuts and less down time for cleaning And because of the advanced process control that is available in ultrasonic generators, cutting performance can be easily manipulated by simply adjusting the equipment parameters.

Ultrasonic food cutting may not be suitable for every food cutting operation. However, high frequency vibration applied to cutting tools does provide significant benefits. Primarily, ultrasonic technology enhances the cut quality and consistency, and offers the ability to cleanly slice multi-textured food products without deformation. Sonics can evaluate the key factors in your food cutting operation to determine if the low friction cutting surface of an ultrasonic knife might be a fit. Contact the experts at Sonics & Materials, Inc. for a detailed review of your cutting needs

Ultrasonic food cutting systems are often used to cut the following types of foods

Hard and soft cheeses, including products containing pieces of nuts and fruit

Sandwiches, wraps, and pizzas for catering industries Nougat, candy bars, granola bars and healthy snack bars Semi-frozen meats and fish

Breads or cake products

Features

| Frequency | 20Khz | Power | 1000w |

|---|---|---|---|

| Horn Material | Titanium | Blade Size | 305mm |

| Generator | Digital | Voltage | 220/110V |

| Application | Ultrasonic Food Cutter | Weight | 15kg |

| High Light | 20Khz Ultrasonic Cutting Machine,Titanium Blade Ultrasonic Cutting Machine,1000w Ultrasonic Cake Cutting Machine | ||

Parameter

| Machine | Ultrasonic cake Cutter |

| Frequency(KHz) | 20Khz |

| Power | 1000 W |

| Cutting Blade / Horn | Titanium |

| Voltage(V) | 220V |

| The width of blade | depend on your requirement |

| Cutting thickness | 86mm in max |

| Horn amplitude | 10-40μm |

| Equipment weight | 8KG |

Introduction

RPS-SONIC offers a complete line of specialized equipment and components for ultrasonic food cutting. Compared to conventional cutters, ultrasonic food cutters are more sanitary, with less down time, better cost-effectiveness and increased consistency at the cutting surface where the blades stay sharp longer.

Cutting tools are manufactured in-house by a precision wire EDM process that reduces stress for longer life. RPS-SONIC provides full customization of OEM components, kits and knife horns. Typical applications include cheese cutting; cake and dessert product cutting; confectionary product cutting; meat cutting; sandwich and wrap cutting.

How ultrasonic cutting system works

Ultrasonic food utting is a process uilizing knives that vibrate at high frequency. Applying ultrasonic vibration to a cutting tool creates a nearly frictionless cutting surface which provides many benefits. This low friction cutting surface can slice a multitude of food products cleanly and without smearing. Very thin slices are also possible due to the reduced resistance. Foods containing items such as vegetables, meats, nuts, berries and fruits can be cut without

deformation or displacement of the internal product. The low friction condition also reduces the tendency of products like nougat and other soft candies from sticking to the cutting tools,

resulting in more consistent cuts and less down time for cleaning And because of the advanced process control that is available in ultrasonic generators, cutting performance can be easily manipulated by simply adjusting the equipment parameters.

Ultrasonic food cutting may not be suitable for every food cutting operation. However, high frequency vibration applied to cutting tools does provide significant benefits. Primarily, ultrasonic technology enhances the cut quality and consistency, and offers the ability to cleanly slice multi-textured food products without deformation. Sonics can evaluate the key factors in your food cutting operation to determine if the low friction cutting surface of an ultrasonic knife might be a fit. Contact the experts at Sonics & Materials, Inc. for a detailed review of your cutting needs

Ultrasonic food cutting systems are often used to cut the following types of foods

Hard and soft cheeses, including products containing pieces of nuts and fruit

Sandwiches, wraps, and pizzas for catering industries Nougat, candy bars, granola bars and healthy snack bars Semi-frozen meats and fish

Breads or cake products

Features

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!