loading

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-C305 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 20Khz | Power | 1000w |

|---|---|---|---|

| Horn Material | Titanium | Blade Size | 305mm |

| Generator | Digital | Voltage | 220/110V |

| Application | Ultrasonic Food Cutter | Weight | 15kg |

| High Light | 1000w Ultrasonic Cake Cutter,Titanium Blade Ultrasonic Cake Cutting Machine,Ultrasonic Cake Cutting Machine 20Khz | ||

Parameter

| Machine | Ultrasonic cake Cutter |

| Frequency(KHz) | 20Khz |

| Power | 1000 W |

| Cutting Blade / Horn | Titanium |

| Voltage(V) | 220V |

| The width of blade | depend on your requirement |

| Cutting thickness | 86mm in max |

| Horn amplitude | 10-40μm |

| Equipment weight | 8KG |

Introduction

As a special cutting tool, the ultrasonic cutting knife has been used to compare with other cutting tools. Ultrasonic cutters have their own advantages in cutting bread, cakes, fruits and other foods. The cutting advantage of the ultrasonic food cutter largely depends on its cutting principle. Secondly, the characteristics of the blade and the materials used in the ultrasonic food cutter can also play a certain role in cutting. Finally, the ultrasonic food cutting knife can play a greater role in specific food cutting, but this does not mean that ultrasonic cutting is suitable for any food.

First of all, learn about the working principle of the ultrasonic cutting knife. The common food cutting appliances on the market, whether they are automated instruments with high technological content or ordinary knives with simple operation, most of the cutting principles are to use the incision of the tool to cut food. It uses the mechanical force of the tool. However, some foods do not require sharp incisions for cutting. On the contrary, food cutting requires a clean cross section and edge sealing. In order to save processing time and simplify the processing process, food cutting tools are also required to have less friction during the cutting process, so as to avoid the frequent need to clean the knives when cutting viscous foods.

In addition, the processing of cakes and breads is often a large-scale cutting process, which requires cutting equipment to be combined with automated equipment to speed up the entire cutting process. Ultrasonic food cutting uses the characteristics of ultrasonic to cut. In addition to the mechanical force of part of the cutter head, the cutting uses high-frequency vibration transmitted by ultrasonic to a greater extent. The vibration frequency can hardly be seen by the naked eye, but the speed is very fast. Usually, the food can be cut only by gently putting the ultrasonic cutting knife into the food. This is also from the other side surface, the ultrasonic cutting knife does not need to use external force to cut. In addition, the high-frequency vibration has another advantage, that is, it can largely avoid the adhesion of food and maintain the cleanliness of the cutter head. After the food processing is completed, only simple cleaning and wiping of the cutter head are required to avoid wear and tear on the cutter head. Frequent cleaning and wiping of knives and instruments will accelerate the damage of knives, which is not conducive to the maintenance of knives.

Another feature of the ultrasonic bakery cutting knife is the ability to heat the cut material during the cutting process. The heating pointer here heats the cut surface, not the whole food. The advantage of heating is that it can seal the edges of the cut food to avoid unevenness in the cutting surface. For frozen products, the benefits of heating are self-evident, and cutting can be completed more quickly and efficiently.

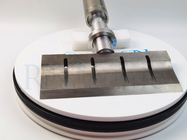

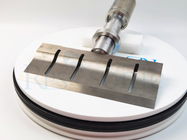

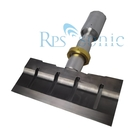

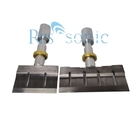

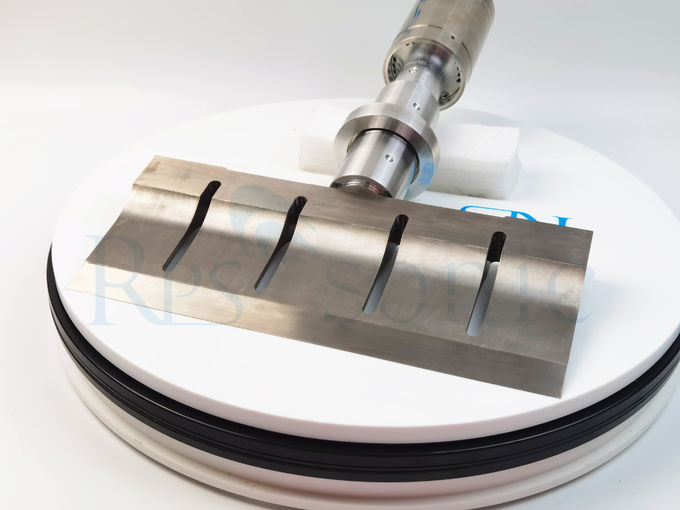

Ultrasonic cutting head

Secondly, the head of the ultrasonic cutting knife is generally made of titanium alloy material. The cutter head made of this material can not only maintain a lighter weight, but also has excellent corrosion resistance. In addition, since frozen food may be encountered during the cutting process, the titanium alloy blade has the ability to withstand this temperature. The head design of the ultrasonic food cutter also has certain characteristics. Compared with other ultrasonic cutting knives, the cutting edge of food cutting knives is wider, and the design of the groove in the middle of the cutter head is often designed. On the one hand, it can reduce the weight of the blade, and on the other hand, it can also increase the overall strength of the cutter head from this structure.

Cutting range

Finally, the ultrasonic bakery cutter is very effective for cutting cakes, cheese, bread, butter and other products. The ultrasonic food cutting knife can give the food a flat cutting surface, and it can be installed on the automatic equipment to complete the cutting efficiently and quickly.

Some foods are annoying during the cutting process, such as cheese, foods with sandwiches, frozen foods, etc. Cheese is sticky in nature, and sticky knives are prone to appear. Foods containing sandwiches, such as common raisin bread, nut bread, etc., have some finer substances inside, so the cutting surface will be uneven during the cutting process. Using ordinary knives to cut frozen foods often requires thawing and then cutting, otherwise it is easy to cause damage to the knives.

Due to the principle and characteristics of the ultrasonic food cutter, the above troubles can be easily solved. It should be noted that ultrasonic food cutting knives can be effective in specific foods, but in the process of cutting raw meat such as pork and beef, it is necessary to avoid using ultrasonic cutting knives.

Pictures

| Frequency | 20Khz | Power | 1000w |

|---|---|---|---|

| Horn Material | Titanium | Blade Size | 305mm |

| Generator | Digital | Voltage | 220/110V |

| Application | Ultrasonic Food Cutter | Weight | 15kg |

| High Light | 1000w Ultrasonic Cake Cutter,Titanium Blade Ultrasonic Cake Cutting Machine,Ultrasonic Cake Cutting Machine 20Khz | ||

Parameter

| Machine | Ultrasonic cake Cutter |

| Frequency(KHz) | 20Khz |

| Power | 1000 W |

| Cutting Blade / Horn | Titanium |

| Voltage(V) | 220V |

| The width of blade | depend on your requirement |

| Cutting thickness | 86mm in max |

| Horn amplitude | 10-40μm |

| Equipment weight | 8KG |

Introduction

As a special cutting tool, the ultrasonic cutting knife has been used to compare with other cutting tools. Ultrasonic cutters have their own advantages in cutting bread, cakes, fruits and other foods. The cutting advantage of the ultrasonic food cutter largely depends on its cutting principle. Secondly, the characteristics of the blade and the materials used in the ultrasonic food cutter can also play a certain role in cutting. Finally, the ultrasonic food cutting knife can play a greater role in specific food cutting, but this does not mean that ultrasonic cutting is suitable for any food.

First of all, learn about the working principle of the ultrasonic cutting knife. The common food cutting appliances on the market, whether they are automated instruments with high technological content or ordinary knives with simple operation, most of the cutting principles are to use the incision of the tool to cut food. It uses the mechanical force of the tool. However, some foods do not require sharp incisions for cutting. On the contrary, food cutting requires a clean cross section and edge sealing. In order to save processing time and simplify the processing process, food cutting tools are also required to have less friction during the cutting process, so as to avoid the frequent need to clean the knives when cutting viscous foods.

In addition, the processing of cakes and breads is often a large-scale cutting process, which requires cutting equipment to be combined with automated equipment to speed up the entire cutting process. Ultrasonic food cutting uses the characteristics of ultrasonic to cut. In addition to the mechanical force of part of the cutter head, the cutting uses high-frequency vibration transmitted by ultrasonic to a greater extent. The vibration frequency can hardly be seen by the naked eye, but the speed is very fast. Usually, the food can be cut only by gently putting the ultrasonic cutting knife into the food. This is also from the other side surface, the ultrasonic cutting knife does not need to use external force to cut. In addition, the high-frequency vibration has another advantage, that is, it can largely avoid the adhesion of food and maintain the cleanliness of the cutter head. After the food processing is completed, only simple cleaning and wiping of the cutter head are required to avoid wear and tear on the cutter head. Frequent cleaning and wiping of knives and instruments will accelerate the damage of knives, which is not conducive to the maintenance of knives.

Another feature of the ultrasonic bakery cutting knife is the ability to heat the cut material during the cutting process. The heating pointer here heats the cut surface, not the whole food. The advantage of heating is that it can seal the edges of the cut food to avoid unevenness in the cutting surface. For frozen products, the benefits of heating are self-evident, and cutting can be completed more quickly and efficiently.

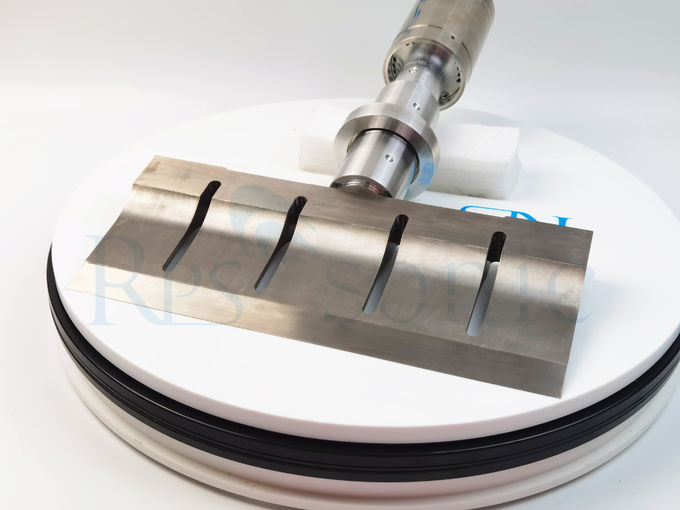

Ultrasonic cutting head

Secondly, the head of the ultrasonic cutting knife is generally made of titanium alloy material. The cutter head made of this material can not only maintain a lighter weight, but also has excellent corrosion resistance. In addition, since frozen food may be encountered during the cutting process, the titanium alloy blade has the ability to withstand this temperature. The head design of the ultrasonic food cutter also has certain characteristics. Compared with other ultrasonic cutting knives, the cutting edge of food cutting knives is wider, and the design of the groove in the middle of the cutter head is often designed. On the one hand, it can reduce the weight of the blade, and on the other hand, it can also increase the overall strength of the cutter head from this structure.

Cutting range

Finally, the ultrasonic bakery cutter is very effective for cutting cakes, cheese, bread, butter and other products. The ultrasonic food cutting knife can give the food a flat cutting surface, and it can be installed on the automatic equipment to complete the cutting efficiently and quickly.

Some foods are annoying during the cutting process, such as cheese, foods with sandwiches, frozen foods, etc. Cheese is sticky in nature, and sticky knives are prone to appear. Foods containing sandwiches, such as common raisin bread, nut bread, etc., have some finer substances inside, so the cutting surface will be uneven during the cutting process. Using ordinary knives to cut frozen foods often requires thawing and then cutting, otherwise it is easy to cause damage to the knives.

Due to the principle and characteristics of the ultrasonic food cutter, the above troubles can be easily solved. It should be noted that ultrasonic food cutting knives can be effective in specific foods, but in the process of cutting raw meat such as pork and beef, it is necessary to avoid using ultrasonic cutting knives.

Pictures

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!