loading

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-C40 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 40Khz | Power | 300w |

|---|---|---|---|

| Horn Material | Titanium | Generator | Digital |

| Voltage | 220/110V | Application | Ultrasonic Fabric Cutter |

| Weight | 6kg | Warranty | One Year |

| High Light | Auto Tracking Handheld Ultrasonic Cutter,Titanium Blade Handheld Ultrasonic Cutter,Ultrasonic Cutting Device 300w | ||

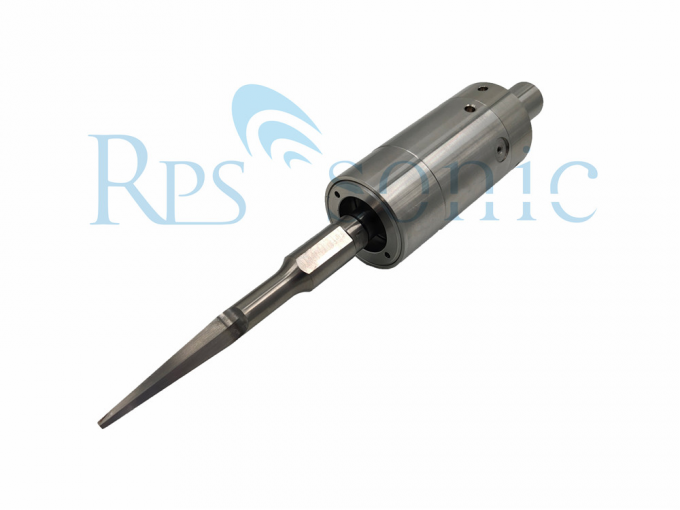

Auto Tracking Ultrasonic Cutting Device 300w 40Khz Handheld With Titanium Blade

40Khz 300w Handheld Ultrasonic cutting device for foam cutting

Parameter

| Frequency | 40Khz |

| Frequency adjustment | Auto-tracking type |

| Max. power output | 300W |

| Power output | Infinitive adjustment |

| Power supply | AC200V 50/60Hz |

| Outer dimension (mm) | 120*120*380 |

| Weight | 6kg |

| Blade thickness | 0.6mm |

RPS-SONIC Ultrasonic cutting systems are ideal for cutting rubber, composite aerospace materials such carbon fiber, Nomex and various honeycombs. RPS-SONIC’s ultrasonic cutting systems can be operated as hand-held units or incorporated into automated machinery. Our applications and design engineering team have developed industry leading tooling to meet the rugged demands of cutting applications. Solid, one-piece construction of horn blade technology virtually eliminates breakage and energy loss. Our robust designs provide minimal blade flexure which yields straight cuts without having to support the blade. RPS-SONIC cutting systems come in 20,30, 35, and 40 kHz frequencies. Where aggressive cuts are needed our 20 kHz ultrasonic generators and tooling are a great solution. If a smaller footprint or lighter payload is needed our 30 and 40 kHz cutting systems are a great fit and provide a quiet operating environment. Our ultrasonic horns designed to work with replaceable carbide cutting blades is a proven solution for aerospace materials that would otherwise not be feasible with standard ultrasonic tooling materials.

Ultrasonic equipment

Ultrasonic machines include ultrasonic processing machine, ultrasonic welding machine, ultrasonic cleaner machine, ultrasonic dispersion machine, ultrasonic measuring instruments, ultrasonic levitation, etc. and we specialize in ultrasonic processing machine. We deal with ultrasonic cutters that can cut materials with less resistance or ultrasonic polisher that can polish metal such as molds with high efficiency by making use of ultrasonic wave to transmit oscillation to tools.

What is the cutting done by the ultrasonic cutter?

Ultrasonic cutter vibrates its blade 20,000 - 40,000 times per second (20 - 40 kHz). Because of this movement, the ultrasonic cutter can easily cut resin, rubber, nonwoven fabric and composite materials. Besides being excellent in maintainability, our products are environment-friendly as they do not substantially discharge any crumbs, waste water, noise, or smoke.

How does ultrasonic cutter work?

Each object has its special frequency, by which the object is stable and easy to oscillate. By adding an external force that corresponds to that special frequency, a small force can obtain a large oscillation. This phenomenon is called resonance. The cutting edge is oscillated greatly with the use of resonance.

The ultrasonic cutter is composed of a "transducer" that generates oscillation and an "oscillator" that drives the transducer. Piezoelectric elements are incorporated in the transducer, and by applying an AC voltage aligned with the characteristic frequency of transducer from the oscillator to the piezoelectric element, the entire vibrator including the cutter blade is resonated. Transducer comes with feedback-control system which transmits information of frequency or amplitude deviation to oscillator caused by cutting load. The feedback-control system can keep resonance state and amplitude of blade stable and it enable the cutters always to cut materials sharply and cleanly.

| Frequency | 40Khz | Power | 300w |

|---|---|---|---|

| Horn Material | Titanium | Generator | Digital |

| Voltage | 220/110V | Application | Ultrasonic Fabric Cutter |

| Weight | 6kg | Warranty | One Year |

| High Light | Auto Tracking Handheld Ultrasonic Cutter,Titanium Blade Handheld Ultrasonic Cutter,Ultrasonic Cutting Device 300w | ||

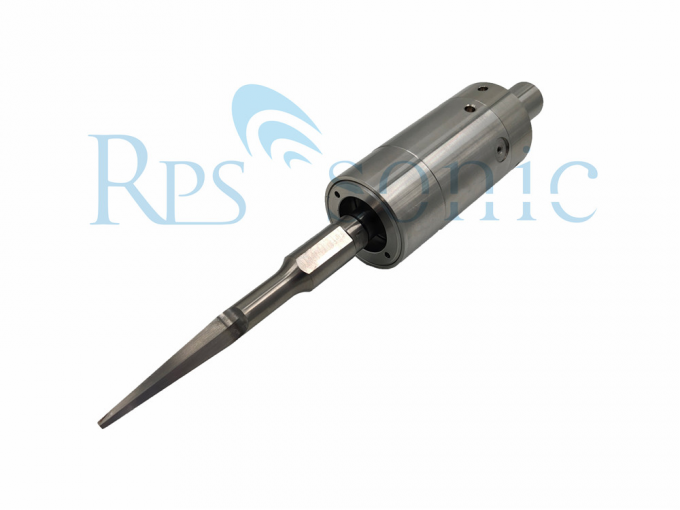

Auto Tracking Ultrasonic Cutting Device 300w 40Khz Handheld With Titanium Blade

40Khz 300w Handheld Ultrasonic cutting device for foam cutting

Parameter

| Frequency | 40Khz |

| Frequency adjustment | Auto-tracking type |

| Max. power output | 300W |

| Power output | Infinitive adjustment |

| Power supply | AC200V 50/60Hz |

| Outer dimension (mm) | 120*120*380 |

| Weight | 6kg |

| Blade thickness | 0.6mm |

RPS-SONIC Ultrasonic cutting systems are ideal for cutting rubber, composite aerospace materials such carbon fiber, Nomex and various honeycombs. RPS-SONIC’s ultrasonic cutting systems can be operated as hand-held units or incorporated into automated machinery. Our applications and design engineering team have developed industry leading tooling to meet the rugged demands of cutting applications. Solid, one-piece construction of horn blade technology virtually eliminates breakage and energy loss. Our robust designs provide minimal blade flexure which yields straight cuts without having to support the blade. RPS-SONIC cutting systems come in 20,30, 35, and 40 kHz frequencies. Where aggressive cuts are needed our 20 kHz ultrasonic generators and tooling are a great solution. If a smaller footprint or lighter payload is needed our 30 and 40 kHz cutting systems are a great fit and provide a quiet operating environment. Our ultrasonic horns designed to work with replaceable carbide cutting blades is a proven solution for aerospace materials that would otherwise not be feasible with standard ultrasonic tooling materials.

Ultrasonic equipment

Ultrasonic machines include ultrasonic processing machine, ultrasonic welding machine, ultrasonic cleaner machine, ultrasonic dispersion machine, ultrasonic measuring instruments, ultrasonic levitation, etc. and we specialize in ultrasonic processing machine. We deal with ultrasonic cutters that can cut materials with less resistance or ultrasonic polisher that can polish metal such as molds with high efficiency by making use of ultrasonic wave to transmit oscillation to tools.

What is the cutting done by the ultrasonic cutter?

Ultrasonic cutter vibrates its blade 20,000 - 40,000 times per second (20 - 40 kHz). Because of this movement, the ultrasonic cutter can easily cut resin, rubber, nonwoven fabric and composite materials. Besides being excellent in maintainability, our products are environment-friendly as they do not substantially discharge any crumbs, waste water, noise, or smoke.

How does ultrasonic cutter work?

Each object has its special frequency, by which the object is stable and easy to oscillate. By adding an external force that corresponds to that special frequency, a small force can obtain a large oscillation. This phenomenon is called resonance. The cutting edge is oscillated greatly with the use of resonance.

The ultrasonic cutter is composed of a "transducer" that generates oscillation and an "oscillator" that drives the transducer. Piezoelectric elements are incorporated in the transducer, and by applying an AC voltage aligned with the characteristic frequency of transducer from the oscillator to the piezoelectric element, the entire vibrator including the cutter blade is resonated. Transducer comes with feedback-control system which transmits information of frequency or amplitude deviation to oscillator caused by cutting load. The feedback-control system can keep resonance state and amplitude of blade stable and it enable the cutters always to cut materials sharply and cleanly.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!