loading

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-LP20 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 20Khz | Power | 1500w |

|---|---|---|---|

| Horn Material | Titanium | Horn Size | Customized |

| Generator | Digital | Weight | 15kg |

| Package | Wooden | Warranty | One Year |

| High Light | Graphene Peeling Ultrasonic Equipment,Titanium Horn Ultrasonic Equipment | ||

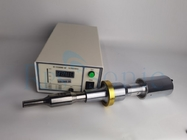

20Khz 1000w Lab Graphene Peeling Ultrasonic Equipment With Titanium Horn

20Khz Lab Ultrasonic graphene preparation and peeling equipment

Description

Graphene powder has the characteristics of fine particle size, high surface energy, large specific surface area, increased number of surface atoms and insufficient atomic coordination, which makes these surface atoms highly reactive, unstable, and easy to agglomerate to form larger agglomerates . The formation of agglomerates makes the nanoparticles cannot be uniformly dispersed in a single particle, and cannot exert their due nano characteristics, which has a great impact on the application performance of the nano powder.

Graphene is insoluble with many substances and has poor dispersibility due to its surface conditions. It is difficult to obtain individual dispersed particles. Then we need to use graphene dispersion ultrasonic equipment to disperse graphene.

The graphene dispersing ultrasonic equipment of our company uses ultrasonic cavitation to disperse agglomerated particles. It is to put the particle suspension (liquid) to be processed into a super-strong sound field and process it with an appropriate ultrasonic amplitude. Due to the inherent characteristics of powder particle agglomeration, for some powders that are not well dispersed in the medium, an appropriate amount of dispersant can be added to maintain a stable dispersion state, especially for dispersing nanomaterials (such as carbon nanotubes, silica, Graphene, etc.) has good effect

Advantages: high dispersion efficiency; the dispersed particles are finer and more uniform; graphene is highly stable: energy saving and environmental protection.

Parameter

| Model | SONOL20-1000 | SONOL20-500 | SONOL28-300 | SONOL40-100 |

| Frequency | 20±0.5 KHz | 20±0.5 KHz | 28±0.5 KHz | 40±0.5 KHz |

| Power | 1000 W | 500 W | 300 W | 100 W |

| Voltage | 220/110V | 220/110V | 220/110V | 220/110V |

| Temperature | 300 ℃ | 300 ℃ | 300 ℃ | 300 ℃ |

| Pressure | 35 MPa | 35 MPa | 35 MPa | 35 MPa |

| Max Capacity | 8 L/Min | 5 L/Min | 1L/Min | 0.5 L/Min |

| Tip Head Material | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Features

Intelligent automatic frequency tracking ultrasonic generator, real-time frequency tracking, to ensure that the ultrasonic wave is in the best effect range;

1000W high-power transducer, low impedance, high conversion efficiency, strong amplitude; titanium alloy extraction application tool head has high conversion efficiency and long service life;

Abnormal protection of frequency, power, transducer current, etc.

Scope of application

1. The fragmentation of cells, bacteria, viruses, spores and other cellular structures

2. Homogeneous soil and rock samples

3. Preparation of DNA fragmentation in high-throughput sequencing and chromatin immunoprecipitation. Research on rock's 4. Structural and physical characteristics

5. Dispersion of pharmaceutical substances for injection

6. The homogenization of beverages by ultrasound

7. Dispersion and extraction of Chinese herbal medicine

8. Alcoholization-aging technology

9. Pyrolysis, emulsification, homogenization and crushing of particulate matter such as carbon nanotubes and rare earth materials to accelerate dissolution and accelerate chemical reactions, such as for the processing of oils and fats.

| Frequency | 20Khz | Power | 1500w |

|---|---|---|---|

| Horn Material | Titanium | Horn Size | Customized |

| Generator | Digital | Weight | 15kg |

| Package | Wooden | Warranty | One Year |

| High Light | Graphene Peeling Ultrasonic Equipment,Titanium Horn Ultrasonic Equipment | ||

20Khz 1000w Lab Graphene Peeling Ultrasonic Equipment With Titanium Horn

20Khz Lab Ultrasonic graphene preparation and peeling equipment

Description

Graphene powder has the characteristics of fine particle size, high surface energy, large specific surface area, increased number of surface atoms and insufficient atomic coordination, which makes these surface atoms highly reactive, unstable, and easy to agglomerate to form larger agglomerates . The formation of agglomerates makes the nanoparticles cannot be uniformly dispersed in a single particle, and cannot exert their due nano characteristics, which has a great impact on the application performance of the nano powder.

Graphene is insoluble with many substances and has poor dispersibility due to its surface conditions. It is difficult to obtain individual dispersed particles. Then we need to use graphene dispersion ultrasonic equipment to disperse graphene.

The graphene dispersing ultrasonic equipment of our company uses ultrasonic cavitation to disperse agglomerated particles. It is to put the particle suspension (liquid) to be processed into a super-strong sound field and process it with an appropriate ultrasonic amplitude. Due to the inherent characteristics of powder particle agglomeration, for some powders that are not well dispersed in the medium, an appropriate amount of dispersant can be added to maintain a stable dispersion state, especially for dispersing nanomaterials (such as carbon nanotubes, silica, Graphene, etc.) has good effect

Advantages: high dispersion efficiency; the dispersed particles are finer and more uniform; graphene is highly stable: energy saving and environmental protection.

Parameter

| Model | SONOL20-1000 | SONOL20-500 | SONOL28-300 | SONOL40-100 |

| Frequency | 20±0.5 KHz | 20±0.5 KHz | 28±0.5 KHz | 40±0.5 KHz |

| Power | 1000 W | 500 W | 300 W | 100 W |

| Voltage | 220/110V | 220/110V | 220/110V | 220/110V |

| Temperature | 300 ℃ | 300 ℃ | 300 ℃ | 300 ℃ |

| Pressure | 35 MPa | 35 MPa | 35 MPa | 35 MPa |

| Max Capacity | 8 L/Min | 5 L/Min | 1L/Min | 0.5 L/Min |

| Tip Head Material | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Features

Intelligent automatic frequency tracking ultrasonic generator, real-time frequency tracking, to ensure that the ultrasonic wave is in the best effect range;

1000W high-power transducer, low impedance, high conversion efficiency, strong amplitude; titanium alloy extraction application tool head has high conversion efficiency and long service life;

Abnormal protection of frequency, power, transducer current, etc.

Scope of application

1. The fragmentation of cells, bacteria, viruses, spores and other cellular structures

2. Homogeneous soil and rock samples

3. Preparation of DNA fragmentation in high-throughput sequencing and chromatin immunoprecipitation. Research on rock's 4. Structural and physical characteristics

5. Dispersion of pharmaceutical substances for injection

6. The homogenization of beverages by ultrasound

7. Dispersion and extraction of Chinese herbal medicine

8. Alcoholization-aging technology

9. Pyrolysis, emulsification, homogenization and crushing of particulate matter such as carbon nanotubes and rare earth materials to accelerate dissolution and accelerate chemical reactions, such as for the processing of oils and fats.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!