loading

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-S20 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 20Khz | Power | 1000w |

|---|---|---|---|

| Generator | Digital | Horn Material | Titanium |

| Type | Rotary Horn | Application | Ultrasonic Nonwoven Sealing Sewing Cutting |

| Weight | 10kg | Speed | 20m/min In Max |

| High Light | 1000watt Ultrasonic Sewing Machine,Titanium Horn Ultrasonic Sewing Equipment,20Khz Ultrasonic Lace Machine | ||

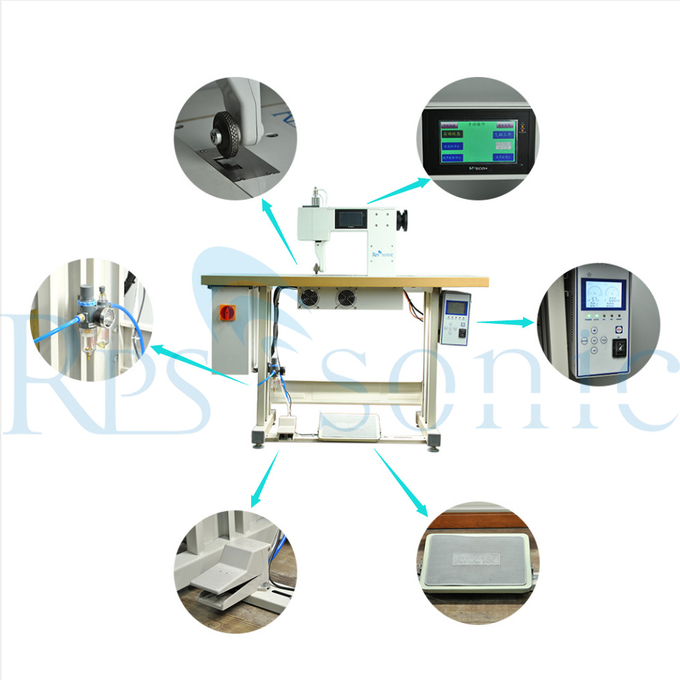

1000watt Titanium Horn Ultrasonic Sewing Machine Continuous Welding

20Khz Textile Ultrasonic sewing Machine with Continuous Welding Force Monitoring

Parameter

| Item | Parameter |

| Frequency | 20Khz |

| Power | 1000W |

| Ceramice chips | 4chips |

| Speed | 20m/min in max |

| Welding width | 15mm in max |

| Welding horn | 20Khz rotary horn |

| Welding type | Continues welding |

Description

Ultrasonic sewing machine, also known as ultrasonic lace machine, ultrasonic embossing machine, is an efficient sewing and embossing equipment. Mainly used for seaming, welding, fusion cutting, embossing, etc. of synthetic fiber fabrics. The processed products have good water tightness, high production efficiency, no needle and thread accessories, smooth fusion cut surface, no burrs, and good hand feeling. Ultrasonic stitching machines are widely used in industries such as clothing, toys, food, environmentally friendly non-woven bags, masks (cup masks, flat masks, three-dimensional masks, etc.)

working principle

The high-frequency oscillation is used to transmit sound waves from the welding head to the welding surface of the work object, and the molecules of the work object are instantly rubbed to reach the melting point of the plastic, thereby completing the rapid dissolution of the solid material and completing the welding.

Applicable materials

Chemical synthetic fiber fabrics, or containing chemical fiber blended patch, chemical film (containing more than 30% chemical fiber), can be processed into the required products, such as Nylon cloth, needle thread patch, non-woven fabric, T/R cloth, special Duolong patch (Polyester cloth), multi-layer cloth, and various laminated surface-coated cloth film papers are all applicable.

Compared with the traditional needle-type wired suture, the ultrasonic suture machine has the following advantages

1. The use of ultrasonic stitching eliminates the need for needles and threads, saves the trouble of frequent needle and thread changes, does not have the disconnected joints of traditional stitches, and can also perform neat partial cutting and sealing of textiles. Stitching also plays a decorative role. It has strong adhesion, can achieve waterproof effect, clear embossing, more three-dimensional relief effect on the surface, fast working speed, good product effect and high-end beauty; quality is guaranteed.

2. The use of Lijin ultrasonic and special steel wheel processing, the sealing edge will not crack, will not damage the edge of the cloth, and there will be no burrs or curling.

3. No preheating is required during manufacturing, and continuous operation is possible.

4. The operation is simple, and it is not much different from the traditional sewing machine operation method, which can be operated by ordinary sewing workers.

5. Low cost, 5 to 6 times faster than traditional machines, and high efficiency.

Application

Clothing lace, bed covers, pillow cases, car covers, tents, packing belts, backpacks, travel belts, hand belts, curtains, raincoats, windbreakers, snow coats, toys, gloves, tablecloths, chair covers, duvet covers, masks, hair Decorations, accessories, umbrellas, lampshades, etc.

| Frequency | 20Khz | Power | 1000w |

|---|---|---|---|

| Generator | Digital | Horn Material | Titanium |

| Type | Rotary Horn | Application | Ultrasonic Nonwoven Sealing Sewing Cutting |

| Weight | 10kg | Speed | 20m/min In Max |

| High Light | 1000watt Ultrasonic Sewing Machine,Titanium Horn Ultrasonic Sewing Equipment,20Khz Ultrasonic Lace Machine | ||

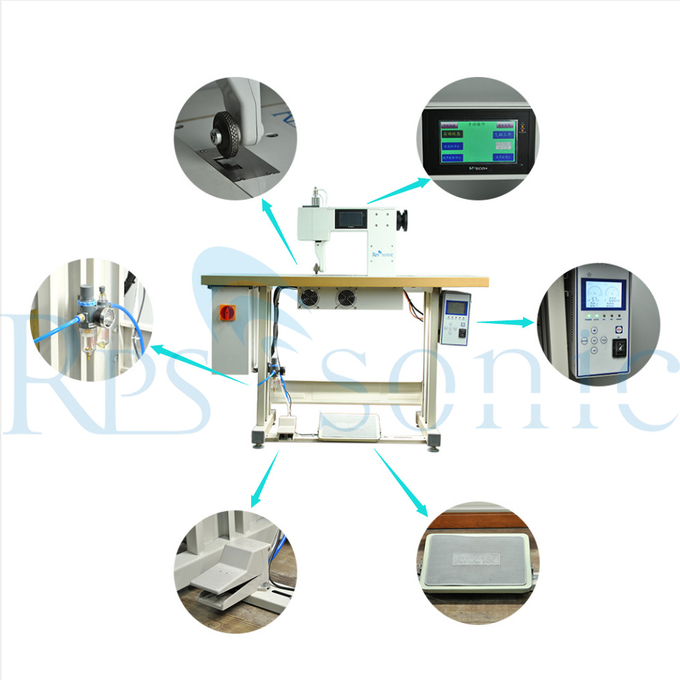

1000watt Titanium Horn Ultrasonic Sewing Machine Continuous Welding

20Khz Textile Ultrasonic sewing Machine with Continuous Welding Force Monitoring

Parameter

| Item | Parameter |

| Frequency | 20Khz |

| Power | 1000W |

| Ceramice chips | 4chips |

| Speed | 20m/min in max |

| Welding width | 15mm in max |

| Welding horn | 20Khz rotary horn |

| Welding type | Continues welding |

Description

Ultrasonic sewing machine, also known as ultrasonic lace machine, ultrasonic embossing machine, is an efficient sewing and embossing equipment. Mainly used for seaming, welding, fusion cutting, embossing, etc. of synthetic fiber fabrics. The processed products have good water tightness, high production efficiency, no needle and thread accessories, smooth fusion cut surface, no burrs, and good hand feeling. Ultrasonic stitching machines are widely used in industries such as clothing, toys, food, environmentally friendly non-woven bags, masks (cup masks, flat masks, three-dimensional masks, etc.)

working principle

The high-frequency oscillation is used to transmit sound waves from the welding head to the welding surface of the work object, and the molecules of the work object are instantly rubbed to reach the melting point of the plastic, thereby completing the rapid dissolution of the solid material and completing the welding.

Applicable materials

Chemical synthetic fiber fabrics, or containing chemical fiber blended patch, chemical film (containing more than 30% chemical fiber), can be processed into the required products, such as Nylon cloth, needle thread patch, non-woven fabric, T/R cloth, special Duolong patch (Polyester cloth), multi-layer cloth, and various laminated surface-coated cloth film papers are all applicable.

Compared with the traditional needle-type wired suture, the ultrasonic suture machine has the following advantages

1. The use of ultrasonic stitching eliminates the need for needles and threads, saves the trouble of frequent needle and thread changes, does not have the disconnected joints of traditional stitches, and can also perform neat partial cutting and sealing of textiles. Stitching also plays a decorative role. It has strong adhesion, can achieve waterproof effect, clear embossing, more three-dimensional relief effect on the surface, fast working speed, good product effect and high-end beauty; quality is guaranteed.

2. The use of Lijin ultrasonic and special steel wheel processing, the sealing edge will not crack, will not damage the edge of the cloth, and there will be no burrs or curling.

3. No preheating is required during manufacturing, and continuous operation is possible.

4. The operation is simple, and it is not much different from the traditional sewing machine operation method, which can be operated by ordinary sewing workers.

5. Low cost, 5 to 6 times faster than traditional machines, and high efficiency.

Application

Clothing lace, bed covers, pillow cases, car covers, tents, packing belts, backpacks, travel belts, hand belts, curtains, raincoats, windbreakers, snow coats, toys, gloves, tablecloths, chair covers, duvet covers, masks, hair Decorations, accessories, umbrellas, lampshades, etc.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!