loading

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-TW20 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 20Khz | Power | 2000w |

|---|---|---|---|

| Horn Material | Alumium Or Titanium Alloy | Application | Ultrasonic Tail Sealing Machine |

| Weight | 20kg | Generator | Digital |

| High Light | 2000w Ultrasonic Tube Sealing Machine,Titanium Horn Ultrasonic Tube Sealing Machine,Titanium Horn Ultrasonic Tube Sealer | ||

20Khz Titanium Horn Ultrasonic Probe 2000w Ultrasonic Tube Sealing Machine

20Khz Titanium horn ultrasonic probe for 2000w ultrasonic tube welding machine

Parameter

| type | TS20 |

| frequency | 20KHz |

| power | 2000watt |

| power supply | AC220v |

| Application | Tube sealing machine |

Description

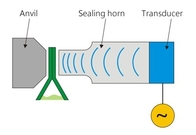

The ultrasonic sealing machine adopts the principle of ultrasonic high frequency vibration.

The machine converts high-frequency electric energy into mechanical energy through the transducer. The energy is transmitted to the hose workpiece through the tool head. With 20,000 times per second ultrasonic frequency and a certain amplitude, the joint surface of the hose workpiece is violently rubbed. Melt and complete the gluing process instantly.

Ultrasonic tail sealing welding machine adopts electronic program control, high degree of automation, easy operation, and built-in electronic protection circuit. The ultrasonic tail sealer has a certain degree of uniformity of the material of the metal tube and the thickness of the tube wall when fusing metal workpieces.

Ultrasonic tail sealing machine does not need any auxiliary products, the sealing speed is fast, the quality is good, and the appearance is beautiful, which solves the shortcomings of using adhesives or hot melt welding.

It is suitable for sealing the ends of various types of hoses such as toothpaste, cosmetics, medicines, food, industrial supplies, etc. The ultrasonic sealing machine uses ultrasonic principles to seal the ends of hoses and composite pipes, with good working stability and high efficiency. All moving components are imported. Material.

Fast, clean and repeatable sealing of plastic or laminated collapsible squeeze tubes in a single step process. Advanced systems offering an energy-saving, environmentally-friendly, efficient process for sealing tubes across a wide range of thermoplastic materials. Systems are available with integral base for manual operation or power head actuator for automated in-line production systems.

Features

Seal All plastic and laminate tubes, ANY shape or size

Production speeds of up to 15 tubes per minute

Date / Lot Coding of all tubes already built-in

Seals through product contamination

Very low reject rate, less than 1%

Ultrasonic sealing eliminates 'flash' and 'ears' versus hot-air sealing methods

Rotary cutting knife to cleanly cut even the thickest tube materials

Change-over time of less than 5 minutes

Virtually NO CHANGE PARTS

Line operators can setup and run machine, no mechanics required

Training new operators is literally a 10-minute procedure, extremely simple

Small footprint, table-top design

Perfect for small production runs and lab use

No warm-up time needed, plug in and it's ready to seal tubes right away

No water requirement

Single phase, 110v power (no 3-phase power required)

Needs only a very small air compressor for air requirements

| Frequency | 20Khz | Power | 2000w |

|---|---|---|---|

| Horn Material | Alumium Or Titanium Alloy | Application | Ultrasonic Tail Sealing Machine |

| Weight | 20kg | Generator | Digital |

| High Light | 2000w Ultrasonic Tube Sealing Machine,Titanium Horn Ultrasonic Tube Sealing Machine,Titanium Horn Ultrasonic Tube Sealer | ||

20Khz Titanium Horn Ultrasonic Probe 2000w Ultrasonic Tube Sealing Machine

20Khz Titanium horn ultrasonic probe for 2000w ultrasonic tube welding machine

Parameter

| type | TS20 |

| frequency | 20KHz |

| power | 2000watt |

| power supply | AC220v |

| Application | Tube sealing machine |

Description

The ultrasonic sealing machine adopts the principle of ultrasonic high frequency vibration.

The machine converts high-frequency electric energy into mechanical energy through the transducer. The energy is transmitted to the hose workpiece through the tool head. With 20,000 times per second ultrasonic frequency and a certain amplitude, the joint surface of the hose workpiece is violently rubbed. Melt and complete the gluing process instantly.

Ultrasonic tail sealing welding machine adopts electronic program control, high degree of automation, easy operation, and built-in electronic protection circuit. The ultrasonic tail sealer has a certain degree of uniformity of the material of the metal tube and the thickness of the tube wall when fusing metal workpieces.

Ultrasonic tail sealing machine does not need any auxiliary products, the sealing speed is fast, the quality is good, and the appearance is beautiful, which solves the shortcomings of using adhesives or hot melt welding.

It is suitable for sealing the ends of various types of hoses such as toothpaste, cosmetics, medicines, food, industrial supplies, etc. The ultrasonic sealing machine uses ultrasonic principles to seal the ends of hoses and composite pipes, with good working stability and high efficiency. All moving components are imported. Material.

Fast, clean and repeatable sealing of plastic or laminated collapsible squeeze tubes in a single step process. Advanced systems offering an energy-saving, environmentally-friendly, efficient process for sealing tubes across a wide range of thermoplastic materials. Systems are available with integral base for manual operation or power head actuator for automated in-line production systems.

Features

Seal All plastic and laminate tubes, ANY shape or size

Production speeds of up to 15 tubes per minute

Date / Lot Coding of all tubes already built-in

Seals through product contamination

Very low reject rate, less than 1%

Ultrasonic sealing eliminates 'flash' and 'ears' versus hot-air sealing methods

Rotary cutting knife to cleanly cut even the thickest tube materials

Change-over time of less than 5 minutes

Virtually NO CHANGE PARTS

Line operators can setup and run machine, no mechanics required

Training new operators is literally a 10-minute procedure, extremely simple

Small footprint, table-top design

Perfect for small production runs and lab use

No warm-up time needed, plug in and it's ready to seal tubes right away

No water requirement

Single phase, 110v power (no 3-phase power required)

Needs only a very small air compressor for air requirements

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!