loading

| Place of Origin | china |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-C20 |

| Minimum Order Quantity | 1 |

| Price | to be negotiated |

| Packaging Details | CARTON |

| Delivery Time | 3-7 WORK DAYS |

| Payment Terms | L/C, D/A, D/P, Western Union, T/T, MoneyGram |

| Supply Ability | 200pcs/month |

| Brand | RPS-SONIC | Frequency | 40khz |

|---|---|---|---|

| Power | 500W | Voltage | 220V / 110V |

| Outer Skin | Aluminum | Power Controller | Stepping Or Continuous |

| Input | AC110-240V, 50/60Hz | Generator | Digital Generator |

| Width Cutter | 82.5mm | ||

| High Light | Handheld Ultrasonic Cutting Machine,Aluminum Ultrasonic Cutting Machine,Aluminum Ultrasonic Cutting Equipment | ||

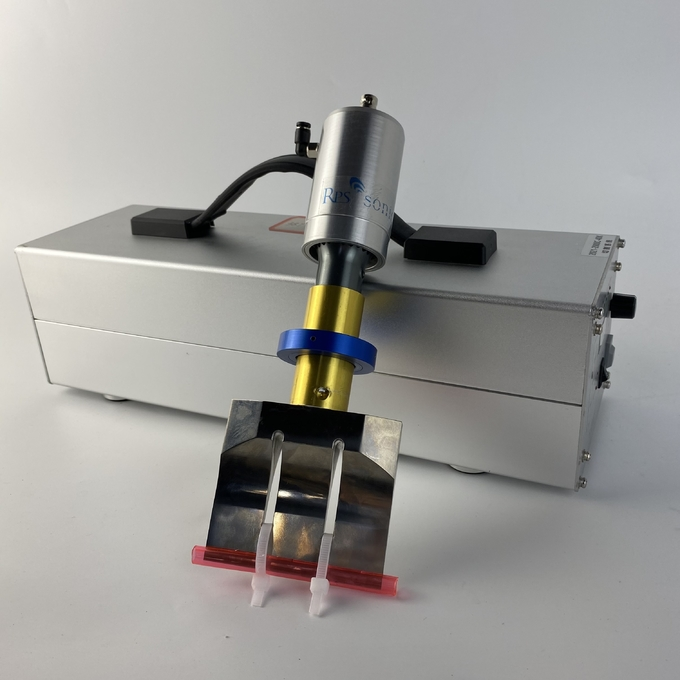

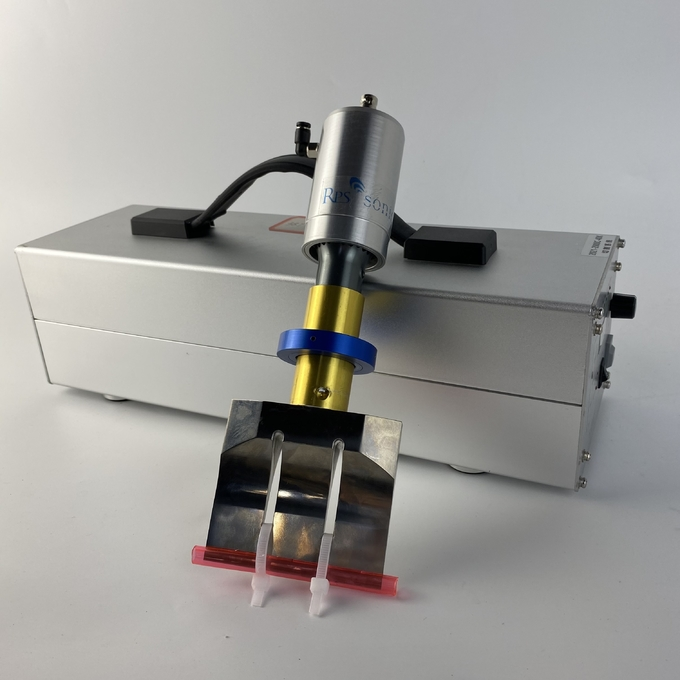

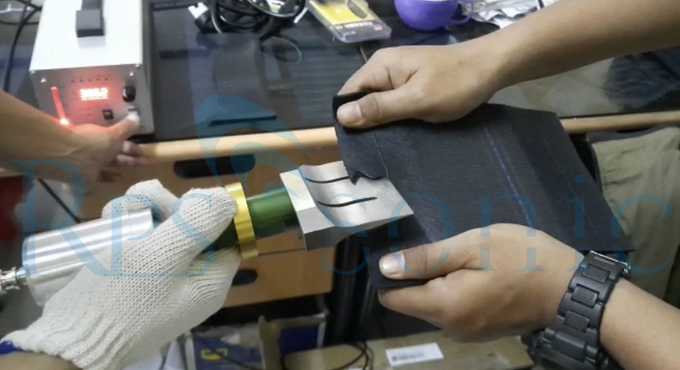

40kHz Handheld Ultrasonic Cutting Machine Rubber Sheet Cutter Equipment

| Model | RPS-C40 |

| Frequency | 40KHZ |

| Power | 500W |

| Generator | Digital Generator |

| width cutter | 82.5mm |

| Input | AC110-240V, 50/60Hz |

| Power controller | stepping or continuous |

| Outer skin | Aluminum |

| Voltage | 220V / 110V |

PRODUCT DETAIL

Ultrasonic equipment is a kind of equipment that converts electrical energy into high-frequency mechanical vibration. It is mainly composed of an

ultrasonic transducer. an horn. a tool head and an ultrasonic aeneratorUltrasonic waves can produce cavitation. mechanical thermal and

chemical effects. and use these effects to achieve the purpose of use

The basic structure of the equipment: ultrasonic vibration parts +ultrasonic drive power

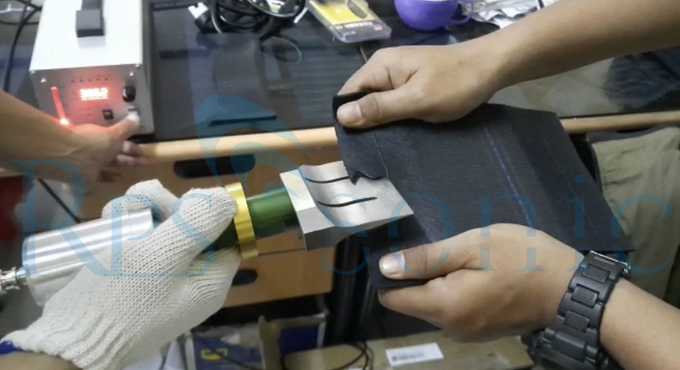

Principle of Ultrasonic Cutting

The principle of ultrasonic cutting knife is to convert 50/60Hz current into 20.30 or 40kHz electric eneray through ultrasonic generator. The

converted high-frequency electric eneray is again convertedinto mechanical vibration of the same frequency through the transducer and then the

mechanical vibration is transmitted to the cutting knife through a set of amplitude modulator devices that can change the amplitude. The ultrasonic

cuttina knife vibrates alona its lenath with an amplitude of 10-70um. repeatina 40.000 times (40 kHz) per second (the vibration of the blade is

microscopic. and it is generally difficult to see with the naked eve).The cutting knife then transfers the received vibration energy to the cuttino

surface of the workpiece to be cut. ln this area, the vibration energy is used to cut the rubber by activating the molecular energy of the rubber and

opening the molecular chain

| Brand | RPS-SONIC | Frequency | 40khz |

|---|---|---|---|

| Power | 500W | Voltage | 220V / 110V |

| Outer Skin | Aluminum | Power Controller | Stepping Or Continuous |

| Input | AC110-240V, 50/60Hz | Generator | Digital Generator |

| Width Cutter | 82.5mm | ||

| High Light | Handheld Ultrasonic Cutting Machine,Aluminum Ultrasonic Cutting Machine,Aluminum Ultrasonic Cutting Equipment | ||

40kHz Handheld Ultrasonic Cutting Machine Rubber Sheet Cutter Equipment

| Model | RPS-C40 |

| Frequency | 40KHZ |

| Power | 500W |

| Generator | Digital Generator |

| width cutter | 82.5mm |

| Input | AC110-240V, 50/60Hz |

| Power controller | stepping or continuous |

| Outer skin | Aluminum |

| Voltage | 220V / 110V |

PRODUCT DETAIL

Ultrasonic equipment is a kind of equipment that converts electrical energy into high-frequency mechanical vibration. It is mainly composed of an

ultrasonic transducer. an horn. a tool head and an ultrasonic aeneratorUltrasonic waves can produce cavitation. mechanical thermal and

chemical effects. and use these effects to achieve the purpose of use

The basic structure of the equipment: ultrasonic vibration parts +ultrasonic drive power

Principle of Ultrasonic Cutting

The principle of ultrasonic cutting knife is to convert 50/60Hz current into 20.30 or 40kHz electric eneray through ultrasonic generator. The

converted high-frequency electric eneray is again convertedinto mechanical vibration of the same frequency through the transducer and then the

mechanical vibration is transmitted to the cutting knife through a set of amplitude modulator devices that can change the amplitude. The ultrasonic

cuttina knife vibrates alona its lenath with an amplitude of 10-70um. repeatina 40.000 times (40 kHz) per second (the vibration of the blade is

microscopic. and it is generally difficult to see with the naked eve).The cutting knife then transfers the received vibration energy to the cuttino

surface of the workpiece to be cut. ln this area, the vibration energy is used to cut the rubber by activating the molecular energy of the rubber and

opening the molecular chain

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!