loading

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-C20-305 |

| Minimum Order Quantity | 1pcs |

| Price | Negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 20Khz | Power | 1000w |

|---|---|---|---|

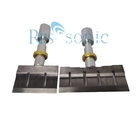

| Blade Material | Titanium | Blade Size | 305mm |

| Weight | 25kg | Generator | Digital |

| Application | Food Cutting | ||

| High Light | Ultrasonic Food Cutting Machine 1000w,Titanium Blade Ultrasonic Food Cutter,Digital Ultrasonic Food Cutter | ||

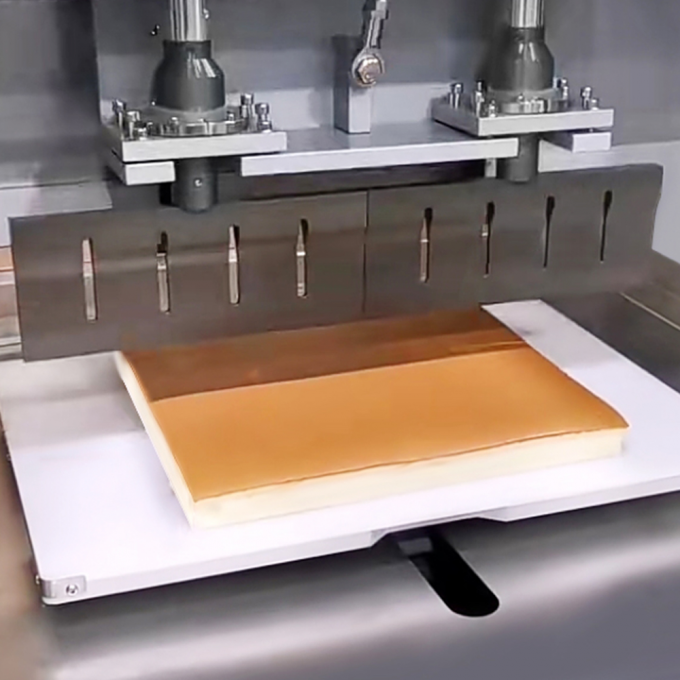

Ultrasonic food cutting machine food cutting machine with titanium blade 1000w

Parameter

| Machine | Ultrasonic cake Cutter |

| Frequency(KHz) | 20KHZ |

| Power | 1000W |

| Cutting Blade / Horn | Titanium |

| The width of blade | 305MM |

| Cutting thickness | 10~20mm(depend on materials) |

| Horn amplitude | 10-40um |

| Equipment weight | 25KG |

Description

Ultrasonic food cutting is a growing sector in the ever changing food manufacturing industry. With the high pace low waste expectation this has led to more manufacturers opting to use ultrasonic cutting in their food manufacturing process to cut down on wastage.

The oscillating titanium blade offers a nearly frictionless cutting action which is extremely precise, allowing the most delicate or textured of products to be cut neatly and effortlessly, leaving a clean and aesthetically pleasing product. From tray bakes, sandwiches, round cakes to extruded foods, ultrasonic cutting could be the solution to your needs.

Ultrasonic food cutter and ultrasonic slicer vibrates its titanium alloy blade on high frequency. Because of this movement, the ultrasonic cutter can easily cut frozen or fresh different types of food such as frozen pastry, frozen cake, pastry, cake, pizza, swiss roll, sandwich, halvah, nougat, cheese, butter, ice cream, pie, loaf, candies, candy bars, fruit bars, protein bars, energy bars, meat, chicken and so on. We can name the ultrasonic cutter and ultrasonic slicer as ultrasonic food slicer, ultrasonic food cutter, food slicing machine, food cutting machine, cake cutter, cake slicer, cake cutting machine, cake slicing machine, cheese slicer, ultrasonic slicing machine, ultrasonic cutting machine, ultrasonic slicer, ultrasonic cutter, sandwich cutting machine, pizza slicing machine, pizza slicer etc...

Non-Stick Ultrasonic Blade is a new type of nano-ultrasonic cutter developed by RPS-SONIC. This non-Stick Ultrasonic Blade has created a new era in the field of ultrasonic cutting knives. It is further optimized and upgraded on the basis of the original ultrasonic cutter. Solve sticky knife problem. Nano-ultrasonic cutters are both high-tech products and black technology products, dedicated to cutting sticky food, such as nougat, marshmallow, jam sandwich food, cream cake and so on. Ultrasonic Knife is made of imported black gold material, black gold, also known as graphene, so Non-Stick Ultrasonic Slicer better performance, more widely used.

A knife blade vibrating at an ultrasonic frequency can easily slice through the material to be cut quickly and precisely without leaving behind any residue in the form of particles.

Ultrasound has been used for years for cutting finished products. The swinging, cold cutting sonotrode reduces resistance in the cutting process and even cleans itself off residue when used with baked goods, energy bars, cheese, pizza, etc.

Benefits of ultrasonic cutting are

Application

| Frequency | 20Khz | Power | 1000w |

|---|---|---|---|

| Blade Material | Titanium | Blade Size | 305mm |

| Weight | 25kg | Generator | Digital |

| Application | Food Cutting | ||

| High Light | Ultrasonic Food Cutting Machine 1000w,Titanium Blade Ultrasonic Food Cutter,Digital Ultrasonic Food Cutter | ||

Ultrasonic food cutting machine food cutting machine with titanium blade 1000w

Parameter

| Machine | Ultrasonic cake Cutter |

| Frequency(KHz) | 20KHZ |

| Power | 1000W |

| Cutting Blade / Horn | Titanium |

| The width of blade | 305MM |

| Cutting thickness | 10~20mm(depend on materials) |

| Horn amplitude | 10-40um |

| Equipment weight | 25KG |

Description

Ultrasonic food cutting is a growing sector in the ever changing food manufacturing industry. With the high pace low waste expectation this has led to more manufacturers opting to use ultrasonic cutting in their food manufacturing process to cut down on wastage.

The oscillating titanium blade offers a nearly frictionless cutting action which is extremely precise, allowing the most delicate or textured of products to be cut neatly and effortlessly, leaving a clean and aesthetically pleasing product. From tray bakes, sandwiches, round cakes to extruded foods, ultrasonic cutting could be the solution to your needs.

Ultrasonic food cutter and ultrasonic slicer vibrates its titanium alloy blade on high frequency. Because of this movement, the ultrasonic cutter can easily cut frozen or fresh different types of food such as frozen pastry, frozen cake, pastry, cake, pizza, swiss roll, sandwich, halvah, nougat, cheese, butter, ice cream, pie, loaf, candies, candy bars, fruit bars, protein bars, energy bars, meat, chicken and so on. We can name the ultrasonic cutter and ultrasonic slicer as ultrasonic food slicer, ultrasonic food cutter, food slicing machine, food cutting machine, cake cutter, cake slicer, cake cutting machine, cake slicing machine, cheese slicer, ultrasonic slicing machine, ultrasonic cutting machine, ultrasonic slicer, ultrasonic cutter, sandwich cutting machine, pizza slicing machine, pizza slicer etc...

Non-Stick Ultrasonic Blade is a new type of nano-ultrasonic cutter developed by RPS-SONIC. This non-Stick Ultrasonic Blade has created a new era in the field of ultrasonic cutting knives. It is further optimized and upgraded on the basis of the original ultrasonic cutter. Solve sticky knife problem. Nano-ultrasonic cutters are both high-tech products and black technology products, dedicated to cutting sticky food, such as nougat, marshmallow, jam sandwich food, cream cake and so on. Ultrasonic Knife is made of imported black gold material, black gold, also known as graphene, so Non-Stick Ultrasonic Slicer better performance, more widely used.

A knife blade vibrating at an ultrasonic frequency can easily slice through the material to be cut quickly and precisely without leaving behind any residue in the form of particles.

Ultrasound has been used for years for cutting finished products. The swinging, cold cutting sonotrode reduces resistance in the cutting process and even cleans itself off residue when used with baked goods, energy bars, cheese, pizza, etc.

Benefits of ultrasonic cutting are

Application

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!