loading

| Place of Origin | china |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-C20 |

| Minimum Order Quantity | 1 |

| Price | to be negotiated |

| Packaging Details | CARTON |

| Delivery Time | 3-7 WORK DAYS |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 200pcs/month |

| Model | RPS-C20 | Frequency | 20KHZ |

|---|---|---|---|

| Power | 1000W | Material Of Blade | Titanium |

| Width Of Blade | 305mm In Max | Thickness Of Cutter | Depend On Your Material |

| Voltage | 220/110V | Generator | Digital Generator |

| High Light | 20k Ultrasonic Cutting Knife,1000W Ultrasonic Cutting Knife,Titanium Ultrasonic Cutting Knife | ||

Description

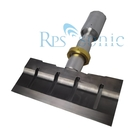

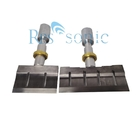

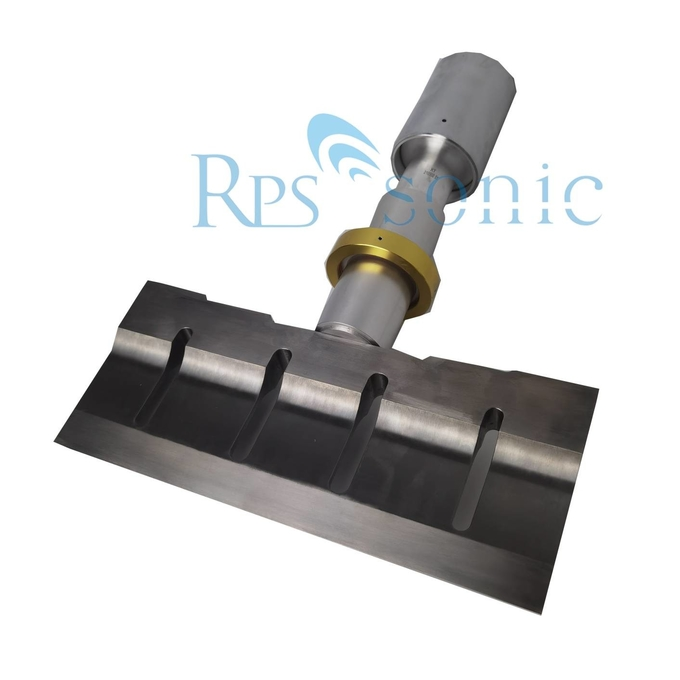

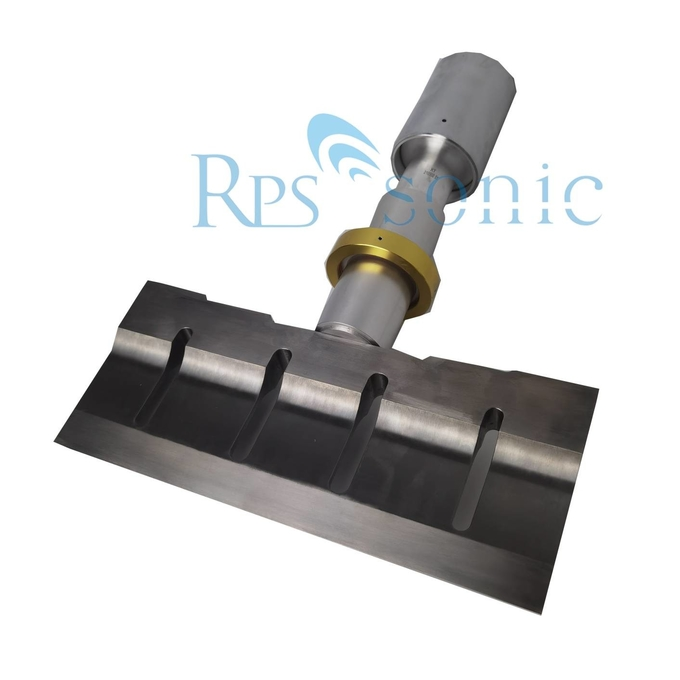

Ultrasonic food cutting knives use high-frequency ultrasonic vibrations and cut with sharp edges to reduce pressure on food and extend tool life. The RPS-SONIC ultrasound equipment provides complete customization of OEM components, kits and corners. Typical applications include cheese cutting, cutting of cake and dessert products, cutting of confectionery products, meat cutting, sandwich and package cutting.

Dairy manufacturers typically use ultrasonic food cutting systems to dispense hard or mild seasoned cheese that is difficult to slice.

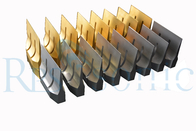

Ultrasonic blades may vary in length and height depending on the customer’s specific requirements. They are made of titanium or stainless steel.

The digital generator for ultrasonic food cutting knives provides the ability to add, reduce and modify its operating parameters, with parameters such as amplitude, output power and time.

For ultrasonic food cutting applications embedded in automated production lines, we offer vibration groups of different frequencies from 20, 30 to 40 kHz according to the requirements of the end user, keeping the work safe and noise free during the manufacturing phase.

| model | RPS-C20 |

| Frequency | 20khz |

| Power | 1000W |

| Voltage | 220V/110V |

| Width of blades | 305mm |

| thickness of blade | depend on your material |

| digital generator | Digital generator |

The difference between traditional cutting and ultrasonic cutting:

The traditional cutting use a sharp edge tool(knife) to press the cutting material. The pressure is concentrated at the edge of the cutter blade, the pressure is very large there. Therefore the cutting effects for soft or flexible material are not good enough, especially more difficult for sticky material.

Ultrasonic cutting technology use of wave energy for cutting, the main feature is it will not have the traditional cutting edge.

Advantages of ultrasonic cutting:

1. Clear, clean, smooth and tidy and cutting surface

2. In addition to cutting, ultrasonic can also dig holes, shovels, scraping, carving, strip, etc

Ultrasonic Components

Typical ultrasonic cutting components include energy transducer, booster and ultrasonic cutting horn. These three major elements all can use titanium alloy.

| Model | RPS-C20 | Frequency | 20KHZ |

|---|---|---|---|

| Power | 1000W | Material Of Blade | Titanium |

| Width Of Blade | 305mm In Max | Thickness Of Cutter | Depend On Your Material |

| Voltage | 220/110V | Generator | Digital Generator |

| High Light | 20k Ultrasonic Cutting Knife,1000W Ultrasonic Cutting Knife,Titanium Ultrasonic Cutting Knife | ||

Description

Ultrasonic food cutting knives use high-frequency ultrasonic vibrations and cut with sharp edges to reduce pressure on food and extend tool life. The RPS-SONIC ultrasound equipment provides complete customization of OEM components, kits and corners. Typical applications include cheese cutting, cutting of cake and dessert products, cutting of confectionery products, meat cutting, sandwich and package cutting.

Dairy manufacturers typically use ultrasonic food cutting systems to dispense hard or mild seasoned cheese that is difficult to slice.

Ultrasonic blades may vary in length and height depending on the customer’s specific requirements. They are made of titanium or stainless steel.

The digital generator for ultrasonic food cutting knives provides the ability to add, reduce and modify its operating parameters, with parameters such as amplitude, output power and time.

For ultrasonic food cutting applications embedded in automated production lines, we offer vibration groups of different frequencies from 20, 30 to 40 kHz according to the requirements of the end user, keeping the work safe and noise free during the manufacturing phase.

| model | RPS-C20 |

| Frequency | 20khz |

| Power | 1000W |

| Voltage | 220V/110V |

| Width of blades | 305mm |

| thickness of blade | depend on your material |

| digital generator | Digital generator |

The difference between traditional cutting and ultrasonic cutting:

The traditional cutting use a sharp edge tool(knife) to press the cutting material. The pressure is concentrated at the edge of the cutter blade, the pressure is very large there. Therefore the cutting effects for soft or flexible material are not good enough, especially more difficult for sticky material.

Ultrasonic cutting technology use of wave energy for cutting, the main feature is it will not have the traditional cutting edge.

Advantages of ultrasonic cutting:

1. Clear, clean, smooth and tidy and cutting surface

2. In addition to cutting, ultrasonic can also dig holes, shovels, scraping, carving, strip, etc

Ultrasonic Components

Typical ultrasonic cutting components include energy transducer, booster and ultrasonic cutting horn. These three major elements all can use titanium alloy.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!