loading

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-R35 |

| Minimum Order Quantity | 1pcs |

| Price | Negotiable |

| Packaging Details | Wooden |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 20PCS/MONTH |

| Frequency | 35khz | Power | 800w |

|---|---|---|---|

| Horn Material | Steel | Hardness | HRC58-62 |

| Wheel Shape | Can Be Customized | Generator | Digital |

| Weight | 120kg | ||

| High Light | Ultrasonic Sewing Equipment 800 Watt,Sonobond Ultrasonic Sewing Machine,Rotary Steel Horn Ultrasonic Sewing Machine | ||

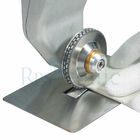

800w high speed Sonobond ultrasonic sewing machine with rotary steel horn

Parameter

| Model | RPS-R35 |

| Frequency | 35KHZ |

| Power | 800W |

| Ceramice chips | 4 chips |

| Running speed | 20m/min in max |

| Welding width | 15mm in max |

| Welding horn | 35Khz rotary horn |

| Generator | digital generator |

Description

Ultrasonic welding is a high-tech technology for welding thermoplastic products. All kinds of thermoplastic plastic parts can be processed by ultrasonic welding without adding solvents, adhesives or other auxiliary materials. Its advantages are to increase multiple productivity, reduce costs, improve product quality and safe production. The power adjustment is finer and the resolution is higher, which can meet the products of various shapes and achieve the purpose of not damaging the products. Ultrasonic transducers are made of high-quality raw materials and processed precisely, so that the ultrasonic airflow can be perfectly exerted at every point.

1. The working principle is to use high-frequency oscillation to transmit the sound wave to the welding surface of the workpiece by the welding head, and instantly make the molecules of the workpiece rub to reach the melting point of the plastic, so as to complete the solid material quickly.

dissolve and complete the welding. The strength of the joint point is close to that of the whole piece of continuous material, as long as the joint surface of the product is designed to match, there is absolutely no problem with complete sealing.

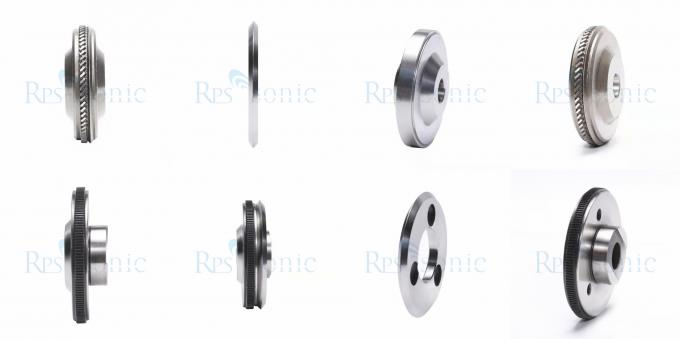

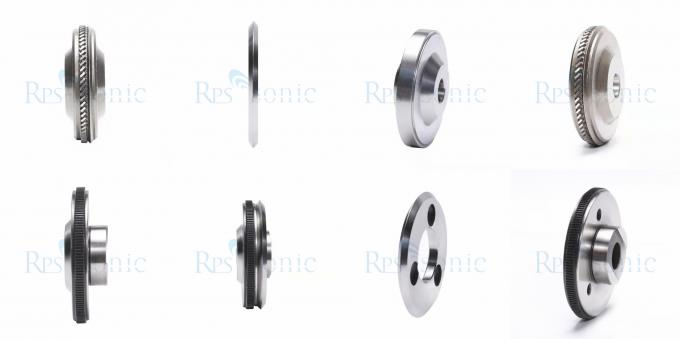

2. The flower wheel mold is made of special alloy steel, and various complex flower-shaped patterns can be developed according to customer needs; the welding head is wear-resistant and has a long life, the flower mold is easy to disassemble and assemble, and the eccentric adjustment

Flexible, fast and high level.

35K ultrasonic non-woven sewing machine, digital ultrasonic seamless sewing machine, Hangzhou ultrasonic sewing machine discount, ultrasonic seamless sewing technology skillfully uses the principle of ultrasonic bending vibration to convert the length of the high-frequency ultrasonic longitudinal vibrator into The diameter of the bending oscillator. Moreover, the vibration direction is also rotated by 90 degrees, converting the longitudinal vibration into the radial vibration of the disc welding head, and the installation method is also changed from vertical cloth installation to parallel cloth installation. This not only greatly reduces the volume of the vibration system itself, but also greatly reduces the installation size, the whole machine is beautiful, the volume is reduced, and the weight is greatly reduced. What is more gratifying is that the output end of the bending disk vibration system is a transverse ultrasonic vibration, and the welding head rotates around its own axis. Just press the pressure roller on the cylindrical surface of the welding head to make it rotate synchronously with the welding head. The fabric to be processed is pulled by the welding head and the pinch roller and passes between them. The cloth is heated and melted under the action of ultrasonic waves, and two or more layers of cloth are bonded together, so as to achieve the purpose of welding the cloth. It has the characteristics of fast welding speed, high precision, beautiful welding seam, low energy consumption and simple operation. The purpose of sewing can be achieved. Here, the rotation of the welding head and the pressure roller is completely synchronous and the same direction, there is no speed difference and angle difference, and the fabric will not be stretched, twisted or deformed, and the precision is extremely high. The cloth is heated and melted under the action of ultrasonic waves, and two or more layers of cloth are bonded together, so as to achieve the purpose of sewing the cloth. If the pressing wheel is replaced with a cutter wheel, it will form a perfect cutting edge and sealing machine, which can cut the fabric and heat-melt the edge at the same time. It has the characteristics of fast welding and cutting speed, high precision, beautiful welding seam, small size, low energy consumption, no noise and so on. It represents the development direction of ultrasonic cutting sewing machine.

Features

The core technology of the ultrasonic sewing machine lies in the use of a disc-shaped welding head for seam welding, which skillfully converts the longitudinal vibration of the transducer into radial vibration that radiates 360° outward in the diameter direction of the disc-shaped welding head. And different from the traditional lace machine, the traditional lace machine is generally composed of a flat tool head and a patterned roller. Since the tool head is stationary, it is easy to cause fabrics such as fabrics to deform and wrinkle during work. The type of seamless sewing equipment uses two discs to vibrate to sew the fabric, which solves this problem very well. This not only greatly reduces the volume of the vibration system itself, but also greatly reduces the installation size. The whole machine is beautiful, the volume is reduced, and the weight is greatly reduced.

High stability: The rotation of the welding wheel and the pressing wheel is completely synchronized during ultrasonic seamless stitching, there is no difference in speed and angle, and the fabric will not be stretched, twisted or deformed, and the precision is extremely high. Thanks to the heat-melting effect, no needle and thread are required, the product is more waterproof, lighter and easier to fold.

Welding and cutting synchronization: Ultrasonic seamless stitching equipment is not only suitable for continuous stitching, but also can cut textiles at the same time as welding, and achieve automatic edge sealing.

No heat radiation: During ultrasonic stitching, the energy penetrates the material layer for welding, and there is no heat radiation. During the continuous stitching process, heat will not be transferred to the product, which is especially beneficial for the packaging of heat-sensitive products.

Controllable welding seam: The fabric is pulled by the welding wheel and the pressing wheel, and passes through it, and the fabric is welded by ultrasonic waves. The size of the welding seam and the embossing can be changed by replacing the pressing wheel, which is more flexible and convenient to use.

| Frequency | 35khz | Power | 800w |

|---|---|---|---|

| Horn Material | Steel | Hardness | HRC58-62 |

| Wheel Shape | Can Be Customized | Generator | Digital |

| Weight | 120kg | ||

| High Light | Ultrasonic Sewing Equipment 800 Watt,Sonobond Ultrasonic Sewing Machine,Rotary Steel Horn Ultrasonic Sewing Machine | ||

800w high speed Sonobond ultrasonic sewing machine with rotary steel horn

Parameter

| Model | RPS-R35 |

| Frequency | 35KHZ |

| Power | 800W |

| Ceramice chips | 4 chips |

| Running speed | 20m/min in max |

| Welding width | 15mm in max |

| Welding horn | 35Khz rotary horn |

| Generator | digital generator |

Description

Ultrasonic welding is a high-tech technology for welding thermoplastic products. All kinds of thermoplastic plastic parts can be processed by ultrasonic welding without adding solvents, adhesives or other auxiliary materials. Its advantages are to increase multiple productivity, reduce costs, improve product quality and safe production. The power adjustment is finer and the resolution is higher, which can meet the products of various shapes and achieve the purpose of not damaging the products. Ultrasonic transducers are made of high-quality raw materials and processed precisely, so that the ultrasonic airflow can be perfectly exerted at every point.

1. The working principle is to use high-frequency oscillation to transmit the sound wave to the welding surface of the workpiece by the welding head, and instantly make the molecules of the workpiece rub to reach the melting point of the plastic, so as to complete the solid material quickly.

dissolve and complete the welding. The strength of the joint point is close to that of the whole piece of continuous material, as long as the joint surface of the product is designed to match, there is absolutely no problem with complete sealing.

2. The flower wheel mold is made of special alloy steel, and various complex flower-shaped patterns can be developed according to customer needs; the welding head is wear-resistant and has a long life, the flower mold is easy to disassemble and assemble, and the eccentric adjustment

Flexible, fast and high level.

35K ultrasonic non-woven sewing machine, digital ultrasonic seamless sewing machine, Hangzhou ultrasonic sewing machine discount, ultrasonic seamless sewing technology skillfully uses the principle of ultrasonic bending vibration to convert the length of the high-frequency ultrasonic longitudinal vibrator into The diameter of the bending oscillator. Moreover, the vibration direction is also rotated by 90 degrees, converting the longitudinal vibration into the radial vibration of the disc welding head, and the installation method is also changed from vertical cloth installation to parallel cloth installation. This not only greatly reduces the volume of the vibration system itself, but also greatly reduces the installation size, the whole machine is beautiful, the volume is reduced, and the weight is greatly reduced. What is more gratifying is that the output end of the bending disk vibration system is a transverse ultrasonic vibration, and the welding head rotates around its own axis. Just press the pressure roller on the cylindrical surface of the welding head to make it rotate synchronously with the welding head. The fabric to be processed is pulled by the welding head and the pinch roller and passes between them. The cloth is heated and melted under the action of ultrasonic waves, and two or more layers of cloth are bonded together, so as to achieve the purpose of welding the cloth. It has the characteristics of fast welding speed, high precision, beautiful welding seam, low energy consumption and simple operation. The purpose of sewing can be achieved. Here, the rotation of the welding head and the pressure roller is completely synchronous and the same direction, there is no speed difference and angle difference, and the fabric will not be stretched, twisted or deformed, and the precision is extremely high. The cloth is heated and melted under the action of ultrasonic waves, and two or more layers of cloth are bonded together, so as to achieve the purpose of sewing the cloth. If the pressing wheel is replaced with a cutter wheel, it will form a perfect cutting edge and sealing machine, which can cut the fabric and heat-melt the edge at the same time. It has the characteristics of fast welding and cutting speed, high precision, beautiful welding seam, small size, low energy consumption, no noise and so on. It represents the development direction of ultrasonic cutting sewing machine.

Features

The core technology of the ultrasonic sewing machine lies in the use of a disc-shaped welding head for seam welding, which skillfully converts the longitudinal vibration of the transducer into radial vibration that radiates 360° outward in the diameter direction of the disc-shaped welding head. And different from the traditional lace machine, the traditional lace machine is generally composed of a flat tool head and a patterned roller. Since the tool head is stationary, it is easy to cause fabrics such as fabrics to deform and wrinkle during work. The type of seamless sewing equipment uses two discs to vibrate to sew the fabric, which solves this problem very well. This not only greatly reduces the volume of the vibration system itself, but also greatly reduces the installation size. The whole machine is beautiful, the volume is reduced, and the weight is greatly reduced.

High stability: The rotation of the welding wheel and the pressing wheel is completely synchronized during ultrasonic seamless stitching, there is no difference in speed and angle, and the fabric will not be stretched, twisted or deformed, and the precision is extremely high. Thanks to the heat-melting effect, no needle and thread are required, the product is more waterproof, lighter and easier to fold.

Welding and cutting synchronization: Ultrasonic seamless stitching equipment is not only suitable for continuous stitching, but also can cut textiles at the same time as welding, and achieve automatic edge sealing.

No heat radiation: During ultrasonic stitching, the energy penetrates the material layer for welding, and there is no heat radiation. During the continuous stitching process, heat will not be transferred to the product, which is especially beneficial for the packaging of heat-sensitive products.

Controllable welding seam: The fabric is pulled by the welding wheel and the pressing wheel, and passes through it, and the fabric is welded by ultrasonic waves. The size of the welding seam and the embossing can be changed by replacing the pressing wheel, which is more flexible and convenient to use.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!