loading

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-C40 |

| Minimum Order Quantity | 1 |

| Price | Negotiation |

| Packaging Details | CARTON |

| Delivery Time | 3 work days after payment |

| Payment Terms | T/T, Western Union,PayPal |

| Supply Ability | 100sets |

| Frequency | 40Khz | Power | 500W |

|---|---|---|---|

| Application | Rubber Cutting | Material | Titanium |

| High Light | 40khz Ultrasonic Cutting Equipment,500w Ultrasonic Cutting Equipment,82mm Ultrasonic Cutting Equipment | ||

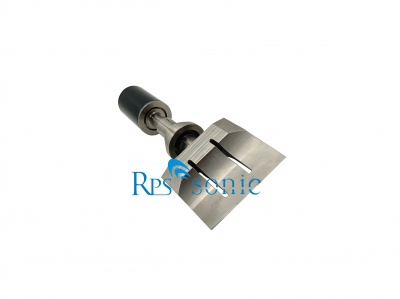

China manufacturer 40khz 500w 82mm ultrasonic rubber cutter machine

Description:

Ultrasonic rubber cutting knife uses the energy of sound waves to cut. It does not require sharp cutting edges or great pressure, and will not cause chipping or damage to the material being cut. Ultrasonic rubber cutting knife can easily cut resin, rubber, non-woven fabric, film, various overlapping composite materials and food.

Specificion:

| Frequency | 40Khz |

| Power | 500W 800W |

| Inupt | AC110-240V, 50/60Hz |

| Power Controller | stepping or continuous |

| Material of Cutting Head | aluminum alloy, stainless steel, titanium alloy, alloy steel. |

| Machine Wight | 4 kg-16KG |

| Accessories | foot switch, additional blade |

| Cooling Device | compressed air mouth can be installed. |

| Cable Length | 2M or customized |

| Foot Switch | available |

Common problems of traditional cutting:

1. Sometimes the production capacity cannot meet the required processing volume. The food to be processed is often prone to deterioration and damage;

2. When some foods are subjected to very intensive processing, they will produce broken particles, crumbs and smash that will soil the plant;

3. Food is composed of different materials and has non-uniform characteristics;

Advantages of ultrasonic cutting:

Advantages of ultrasonic tire rubber cutting

High cutting precision, no deformation of rubber

Good cut surface finish and good bonding performance

Easy to apply to automated production

Fast speed, high efficiency, no pollution

Applications:

1. Tire crown

2. Nylon

3. Steel ribbon plastic layer

4. Nylon cord;

5. Lined

6. Sidewall

7. Apex

8. Triangular circle

Detailed Image:

| Frequency | 40Khz | Power | 500W |

|---|---|---|---|

| Application | Rubber Cutting | Material | Titanium |

| High Light | 40khz Ultrasonic Cutting Equipment,500w Ultrasonic Cutting Equipment,82mm Ultrasonic Cutting Equipment | ||

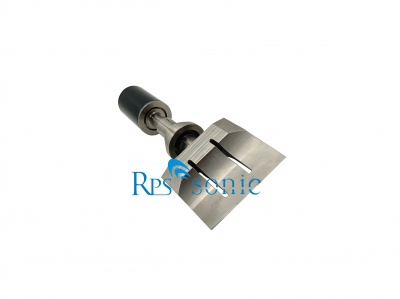

China manufacturer 40khz 500w 82mm ultrasonic rubber cutter machine

Description:

Ultrasonic rubber cutting knife uses the energy of sound waves to cut. It does not require sharp cutting edges or great pressure, and will not cause chipping or damage to the material being cut. Ultrasonic rubber cutting knife can easily cut resin, rubber, non-woven fabric, film, various overlapping composite materials and food.

Specificion:

| Frequency | 40Khz |

| Power | 500W 800W |

| Inupt | AC110-240V, 50/60Hz |

| Power Controller | stepping or continuous |

| Material of Cutting Head | aluminum alloy, stainless steel, titanium alloy, alloy steel. |

| Machine Wight | 4 kg-16KG |

| Accessories | foot switch, additional blade |

| Cooling Device | compressed air mouth can be installed. |

| Cable Length | 2M or customized |

| Foot Switch | available |

Common problems of traditional cutting:

1. Sometimes the production capacity cannot meet the required processing volume. The food to be processed is often prone to deterioration and damage;

2. When some foods are subjected to very intensive processing, they will produce broken particles, crumbs and smash that will soil the plant;

3. Food is composed of different materials and has non-uniform characteristics;

Advantages of ultrasonic cutting:

Advantages of ultrasonic tire rubber cutting

High cutting precision, no deformation of rubber

Good cut surface finish and good bonding performance

Easy to apply to automated production

Fast speed, high efficiency, no pollution

Applications:

1. Tire crown

2. Nylon

3. Steel ribbon plastic layer

4. Nylon cord;

5. Lined

6. Sidewall

7. Apex

8. Triangular circle

Detailed Image:

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!