loading

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-C40 |

| Material | Rapid Steel | Frequency | 40Khz |

|---|---|---|---|

| Power | 300W | Dimention | 120*120*380mm |

| Weight | 5Kgs | Blade Width | 5mm |

| High Light | 300W Ultrasonic Fabric Cutter,40Khz Ultrasonic Fabric Cutter,Rapid Steel Ultrasonic Slitting Machine | ||

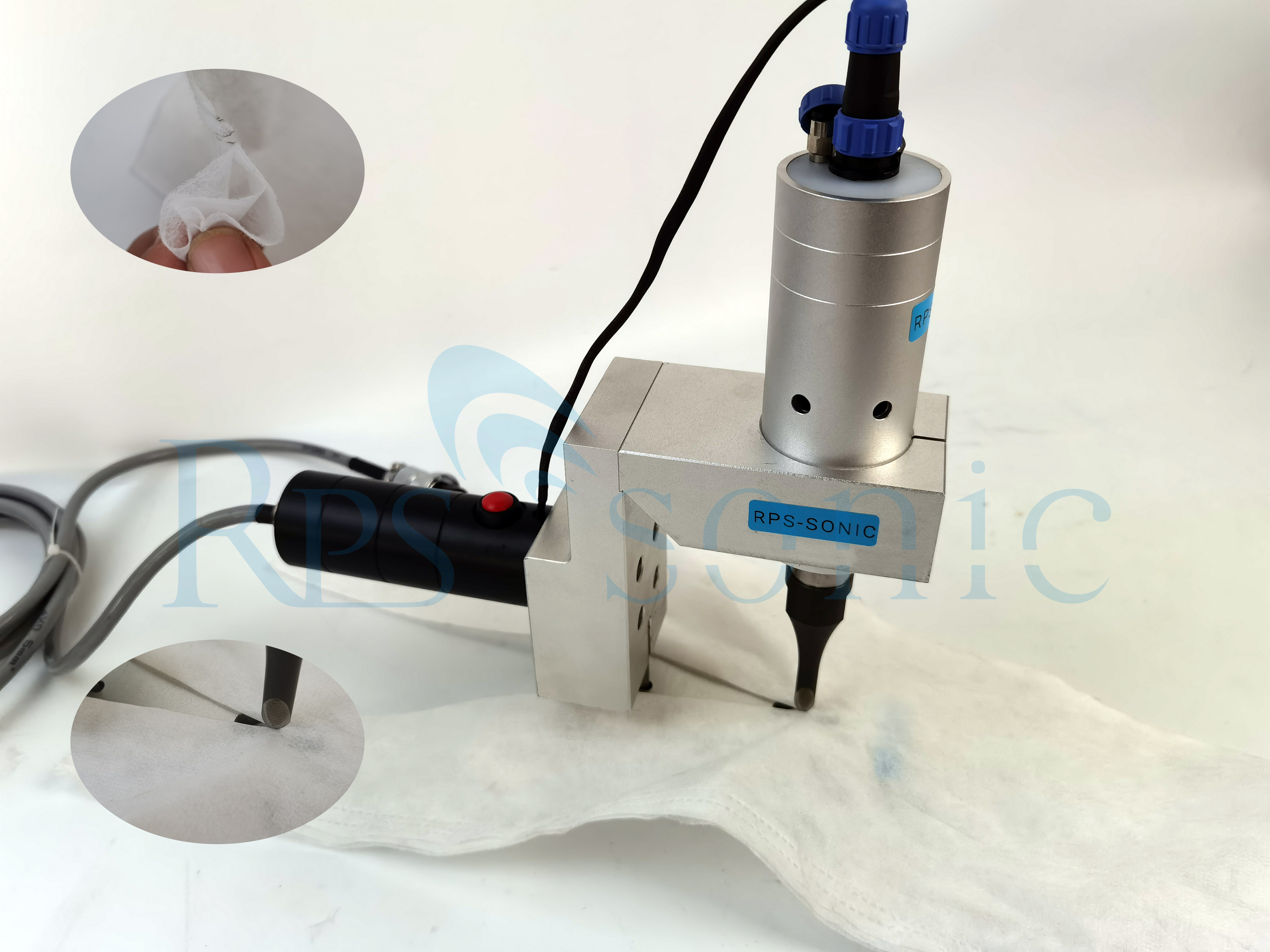

40Khz 300W Ultrasonic Slitter With Cutting And Sealing Function For Non-Woven Fabrics,Foil And Rubber Materials

Ultrasonic Fabric Cutter. This machine is specially engineered for cutting all types of fabrics. Our cutting machine cut all fabrics with a superb edge seal, which prevents fraying. We integrate advanced technology in this Ultrasonic Fabric Cutter for its fully automated and precise operation.

Advantages:

Real time frequency automatic tracking display

Welding modes: time, energy, and grounding.

Amplitude division function

Welding amplitude 10%-100% adjustable (1% accuracy)

Amplitude compensation

Mold impedance analysis + protection

Overload protection

Voltage protection (input)

Transducer voltage protection

485 communication

The Ultrasonic Cutting Systems can easily cut to Food (Cakes, Pies, Fish, Snack, Meat, baked Cokkies, Chees, Vegatables, Candy, Confectionery, Ice Cream) Rubber, Tyre, Resin, Cloths Non-Woven, Film, Ribbon, CD, Foam, Cardboards, Bonded Textile, Craft items, Glass and composite material in which various products.

The Ultrasonic cutting horn, which is vibrating at a high frequency, creates a nearly friction-free environment between the horn and the product, its blade vibrate with an amplitude of 10-70 µm in the longitudinal friction. The vibration is microscopic, so it cannot be seen The movement repeats 20,000 â 40,000 times per seconds (20 Khz â 40 Khz ).

Features

Frequency 40Khz

Compact Ultrasonic cutting machine for cutting of fabrics, non-woven materials, foils, Butyl Rubber (Tyre) etc.

Ideal for straight and curved cutting.

With guiding rail on a cutting table the ideal cutting unit also for larger series.

Cost-efficient Ultrasonic Cutting equipment for studios, small and medium-sized enterprises.

At best adequate for single cuts as well as for small up to medium series

Can be integrated to weaving, winding and other offline applications

Introduction:

Ultrasonic Slitting/Sealing,40Khz Ultrasonic Cutting And Sealing Equipment for Processing And Trimming The Edge of The Blanket,Ultrasonic slitters cleanly cut and seal the edges of synthetic or blended fabrics, eliminating the disadvantages of hot wire or rotating knives. Fraying, unraveling, or beading along the cut edge are eliminated.

Slitters may be mounted on a loom to cut the non-selvedge edge of woven fabric. Equipment is available to operate at the slow speed of weaving looms without burning or beading me fabrics. With special framework and motor drive, crosscuts can be made on the loom.

Parameter:

| Frequency | 40Khz |

| Frequency adjustment | Auto-tracking type |

| Max. power output | 300W |

| Power output | Infinitive adjustment |

| Power supply | AC200V 50/60Hz |

| Outer dimension (mm) | 120*120*380 |

| Weight | 5kg |

| Horn width | 0.5mm |

Ultrasonic cutting sewing equipment is mainly suitable for fabric, suitable materials such as butyrate, cellulose, nylon, polyester, polyethylene, polypropylene, PVC and other materials. It is also suitable for a wide range of tubing in automotive, metal, pharmaceutical, food, cosmetic, medical and scientific applications.

Process flexibility

Enhanced precision

Cleaning edages

cost reduce

Energy efficient

worker safety

Enviroment Friendly

No water waste disposal

| Material | Rapid Steel | Frequency | 40Khz |

|---|---|---|---|

| Power | 300W | Dimention | 120*120*380mm |

| Weight | 5Kgs | Blade Width | 5mm |

| High Light | 300W Ultrasonic Fabric Cutter,40Khz Ultrasonic Fabric Cutter,Rapid Steel Ultrasonic Slitting Machine | ||

40Khz 300W Ultrasonic Slitter With Cutting And Sealing Function For Non-Woven Fabrics,Foil And Rubber Materials

Ultrasonic Fabric Cutter. This machine is specially engineered for cutting all types of fabrics. Our cutting machine cut all fabrics with a superb edge seal, which prevents fraying. We integrate advanced technology in this Ultrasonic Fabric Cutter for its fully automated and precise operation.

Advantages:

Real time frequency automatic tracking display

Welding modes: time, energy, and grounding.

Amplitude division function

Welding amplitude 10%-100% adjustable (1% accuracy)

Amplitude compensation

Mold impedance analysis + protection

Overload protection

Voltage protection (input)

Transducer voltage protection

485 communication

The Ultrasonic Cutting Systems can easily cut to Food (Cakes, Pies, Fish, Snack, Meat, baked Cokkies, Chees, Vegatables, Candy, Confectionery, Ice Cream) Rubber, Tyre, Resin, Cloths Non-Woven, Film, Ribbon, CD, Foam, Cardboards, Bonded Textile, Craft items, Glass and composite material in which various products.

The Ultrasonic cutting horn, which is vibrating at a high frequency, creates a nearly friction-free environment between the horn and the product, its blade vibrate with an amplitude of 10-70 µm in the longitudinal friction. The vibration is microscopic, so it cannot be seen The movement repeats 20,000 â 40,000 times per seconds (20 Khz â 40 Khz ).

Features

Frequency 40Khz

Compact Ultrasonic cutting machine for cutting of fabrics, non-woven materials, foils, Butyl Rubber (Tyre) etc.

Ideal for straight and curved cutting.

With guiding rail on a cutting table the ideal cutting unit also for larger series.

Cost-efficient Ultrasonic Cutting equipment for studios, small and medium-sized enterprises.

At best adequate for single cuts as well as for small up to medium series

Can be integrated to weaving, winding and other offline applications

Introduction:

Ultrasonic Slitting/Sealing,40Khz Ultrasonic Cutting And Sealing Equipment for Processing And Trimming The Edge of The Blanket,Ultrasonic slitters cleanly cut and seal the edges of synthetic or blended fabrics, eliminating the disadvantages of hot wire or rotating knives. Fraying, unraveling, or beading along the cut edge are eliminated.

Slitters may be mounted on a loom to cut the non-selvedge edge of woven fabric. Equipment is available to operate at the slow speed of weaving looms without burning or beading me fabrics. With special framework and motor drive, crosscuts can be made on the loom.

Parameter:

| Frequency | 40Khz |

| Frequency adjustment | Auto-tracking type |

| Max. power output | 300W |

| Power output | Infinitive adjustment |

| Power supply | AC200V 50/60Hz |

| Outer dimension (mm) | 120*120*380 |

| Weight | 5kg |

| Horn width | 0.5mm |

Ultrasonic cutting sewing equipment is mainly suitable for fabric, suitable materials such as butyrate, cellulose, nylon, polyester, polyethylene, polypropylene, PVC and other materials. It is also suitable for a wide range of tubing in automotive, metal, pharmaceutical, food, cosmetic, medical and scientific applications.

Process flexibility

Enhanced precision

Cleaning edages

cost reduce

Energy efficient

worker safety

Enviroment Friendly

No water waste disposal

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!