loading

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-C305 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 20Khz | Power | 1000w |

|---|---|---|---|

| Blade Size | 305mm | Blade Material | Titanium |

| Generator | Digital | Weight | 15kg |

| Voltage(V) | 220V |

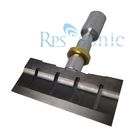

305mm Ultrasonic Cutting Blade for cake bread cutting with Titanium material

Welcome automation ultrasonics cutting systerm cooperate with us all over the world.

| Machine | Ultrasonic rubber/cake Cutter |

| Frequency(KHz) | 20Khz |

| Power | 1000 W |

| Cutting Blade / Horn | Titanium |

| Voltage(V) | 220V |

| The width of blade | depend on your requirement |

| Cutting thickness | 10~20mm(depend on materials) |

| Horn amplitude | 10-40μm |

| Equipment weight | 1KG |

Ultrasonic food cutter features

1. High cutting precision and constant material shape.

2. easy to apply to automated production.

3. the cutting surface has good finish and good bonding performance.

4. fast, high efficiency, no pollution.

We have hand-held cutters and fully automatic cutters. The hand-held cutter is small, beautiful in appearance and easy to operate. It can be replaced with different specifications and different material cutting knives to achieve the ideal cutting equipment. The fully automatic cutting equipment is equipped with a computer-controlled cutting head for the cutting of batches of material.

This ultrasonic food cutter uses ultrasonic vibration to reduce the frictional resistance between the blade and the food. It cuts the blade smoothly, reduces food debris during the cutting process, and increases productivity. It uses a vibrating handle that is simple to operate and quiet and silent when cutting, without vibration. This device vibrates at a high frequency of 40KHZ or 20KHZ. This low friction allows the cutting blade to cut food smoothly, making the cut surface of the food clean, beautiful and non-deformable.

Jiayuanda Technology - Professional ultrasonic food cutter manufacturers and suppliers in China, providing ultrasonic products for sale. Welcome to wholesale the best ultrasonic food cutter at competitive price from our factory.

We are a highly professional and experienced manufacturer of ultrasonic machine equipment in China. We manufacture and supply a wide range ultrasonic equipment to customers across the world. We develop a full line of cutting system components, kits and cutting horns, offering superior performance in terms of speed, safety, sanitation, reliability, and cost-effectiveness. When used for guillotine cutting or continuous slitting, our high frequency vibrating horns cut faster and cleaner than conventional motionless cutters.

The ultrasonic cutting horn, which is vibrating at a high frequency, creates a nearly friction-free environment between the horn and the food product. Because the horn is vibrating at such a high frequency, it disrupts the air molecules around it causing a cocoon effect. This cocoon effect virtually eliminates product sticking and with reduced friction, the ultrasonic horn stays sharper longer than conventional cutters.

With our full customization service for OEMs, we can respond to unique customer requirements, and build components, horns and blades to meet the specific needs of your system configuration and processing application.

Application

Ultrasonic cutters can be used for divided creamed multi-layer cakes, laminated mousse cakes, jujube cakes, steamed sandwich cakes, Napoleon, Swiss rolls, brownies, tiramisu, cheese, ham sandwich sandwiches and other baked goods. It can cut a variety of baked and frozen foods, such as round, square, fan, triangle, etc. And we can provide customized ultrasonic solutions according to customer needs and existing conditions. Welcome to sample testing.

The basic structure of the acoustic wave cutting machine: Ultrasonic transducer, ultrasonic horn, ultrasonic cutter, ultrasonic generator.

Ultrasonic generator

The utility power is converted into a high-frequency high-voltage alternating current and transmitted to an ultrasonic transducer. An ultrasonic transducer is equivalent to an energy conversion device that converts input electrical energy into mechanical energy, that is, ultrasonic waves. The ultrasonic transducer rotates back and forth in the longitudinal direction, and the frequency of the telescopic movement is equal to the frequency of the high-frequency alternating current supplied by the driving power source.

Ultrasonic transducer with booster

The ultrasonic horn amplifies the output amplitude of the ultrasonic transducer.

Ultrasonic cutting knife

Further amplify the amplitude and focus the ultrasound.

The ultrasonic waves are output, and the ultrasonic energy is concentratedly input to the cutting portion of the material to be cut by the cutter. Under the action of huge ultrasonic energy, this part softens and melts instantly, and the strength is greatly reduced. Cutting the material is achieved with a small amount of force.

| Frequency | 20Khz | Power | 1000w |

|---|---|---|---|

| Blade Size | 305mm | Blade Material | Titanium |

| Generator | Digital | Weight | 15kg |

| Voltage(V) | 220V |

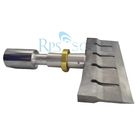

305mm Ultrasonic Cutting Blade for cake bread cutting with Titanium material

Welcome automation ultrasonics cutting systerm cooperate with us all over the world.

| Machine | Ultrasonic rubber/cake Cutter |

| Frequency(KHz) | 20Khz |

| Power | 1000 W |

| Cutting Blade / Horn | Titanium |

| Voltage(V) | 220V |

| The width of blade | depend on your requirement |

| Cutting thickness | 10~20mm(depend on materials) |

| Horn amplitude | 10-40μm |

| Equipment weight | 1KG |

Ultrasonic food cutter features

1. High cutting precision and constant material shape.

2. easy to apply to automated production.

3. the cutting surface has good finish and good bonding performance.

4. fast, high efficiency, no pollution.

We have hand-held cutters and fully automatic cutters. The hand-held cutter is small, beautiful in appearance and easy to operate. It can be replaced with different specifications and different material cutting knives to achieve the ideal cutting equipment. The fully automatic cutting equipment is equipped with a computer-controlled cutting head for the cutting of batches of material.

This ultrasonic food cutter uses ultrasonic vibration to reduce the frictional resistance between the blade and the food. It cuts the blade smoothly, reduces food debris during the cutting process, and increases productivity. It uses a vibrating handle that is simple to operate and quiet and silent when cutting, without vibration. This device vibrates at a high frequency of 40KHZ or 20KHZ. This low friction allows the cutting blade to cut food smoothly, making the cut surface of the food clean, beautiful and non-deformable.

Jiayuanda Technology - Professional ultrasonic food cutter manufacturers and suppliers in China, providing ultrasonic products for sale. Welcome to wholesale the best ultrasonic food cutter at competitive price from our factory.

We are a highly professional and experienced manufacturer of ultrasonic machine equipment in China. We manufacture and supply a wide range ultrasonic equipment to customers across the world. We develop a full line of cutting system components, kits and cutting horns, offering superior performance in terms of speed, safety, sanitation, reliability, and cost-effectiveness. When used for guillotine cutting or continuous slitting, our high frequency vibrating horns cut faster and cleaner than conventional motionless cutters.

The ultrasonic cutting horn, which is vibrating at a high frequency, creates a nearly friction-free environment between the horn and the food product. Because the horn is vibrating at such a high frequency, it disrupts the air molecules around it causing a cocoon effect. This cocoon effect virtually eliminates product sticking and with reduced friction, the ultrasonic horn stays sharper longer than conventional cutters.

With our full customization service for OEMs, we can respond to unique customer requirements, and build components, horns and blades to meet the specific needs of your system configuration and processing application.

Application

Ultrasonic cutters can be used for divided creamed multi-layer cakes, laminated mousse cakes, jujube cakes, steamed sandwich cakes, Napoleon, Swiss rolls, brownies, tiramisu, cheese, ham sandwich sandwiches and other baked goods. It can cut a variety of baked and frozen foods, such as round, square, fan, triangle, etc. And we can provide customized ultrasonic solutions according to customer needs and existing conditions. Welcome to sample testing.

The basic structure of the acoustic wave cutting machine: Ultrasonic transducer, ultrasonic horn, ultrasonic cutter, ultrasonic generator.

Ultrasonic generator

The utility power is converted into a high-frequency high-voltage alternating current and transmitted to an ultrasonic transducer. An ultrasonic transducer is equivalent to an energy conversion device that converts input electrical energy into mechanical energy, that is, ultrasonic waves. The ultrasonic transducer rotates back and forth in the longitudinal direction, and the frequency of the telescopic movement is equal to the frequency of the high-frequency alternating current supplied by the driving power source.

Ultrasonic transducer with booster

The ultrasonic horn amplifies the output amplitude of the ultrasonic transducer.

Ultrasonic cutting knife

Further amplify the amplitude and focus the ultrasound.

The ultrasonic waves are output, and the ultrasonic energy is concentratedly input to the cutting portion of the material to be cut by the cutter. Under the action of huge ultrasonic energy, this part softens and melts instantly, and the strength is greatly reduced. Cutting the material is achieved with a small amount of force.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!