loading

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-LP20 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 20Khz | Power | 2000w |

|---|---|---|---|

| Horn Material | Titanium | Horn Size | Customized |

| Generator | Digital | Weight | 15kg |

| Package | Wooden | Warranty | One Year |

| High Light | Titanium Alloy Ultrasonic Extraction Equipment,1000w Ultrasonic Extraction Equipment,20Khz Ultrasonic Extraction Machine | ||

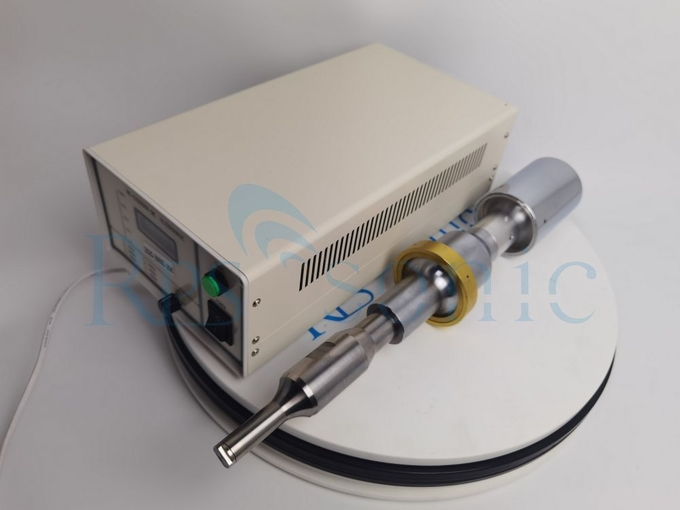

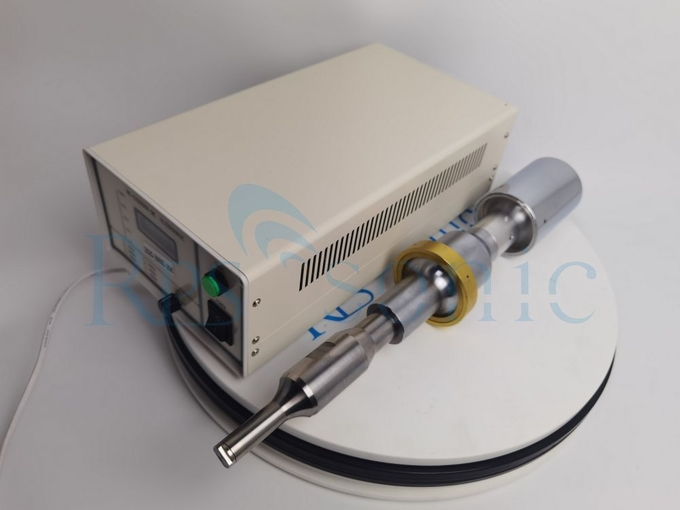

Titanium Alloy 20Khz 1000watt Ultrasonic Extraction Equipment For Plant Essential Oil

20Khz 1000w Ultrasonic extraction equipment for Plant essential oil extraction

Features

Compared with conventional extraction technology, ultrasonic extraction is fast, inexpensive and efficient.

Compared with the water boiling and alcohol precipitation process, ultrasonic extraction has the following outstanding features:

1. No need for high temperature.

2. Atmospheric extraction, good safety, simple operation and convenient maintenance.

3. High extraction efficiency.

4. Has a broad spectrum. Wide applicability, most of the various components of Chinese medicinal materials can be extracted ultrasonically.

5. Ultrasonic extraction has little relationship with the properties of the solvent and the target extract.

6. Reduce energy consumption.

7. The processing capacity of medicinal materials is large, which is doubled or several times higher, and there are few impurities, and the effective ingredients are easy to separate and purify. 8. The extraction process has low cost and significant comprehensive economic benefits.

Parameter

| Model | SONOL20-1000 | SONOL20-500 | SONOL28-300 | SONOL40-100 |

| Frequency | 20±0.5 KHz | 20±0.5 KHz | 28±0.5 KHz | 40±0.5 KHz |

| Power | 1000 W | 500 W | 300 W | 100 W |

| Voltage | 220/110V | 220/110V | 220/110V | 220/110V |

| Temperature | 300 ℃ | 300 ℃ | 300 ℃ | 300 ℃ |

| Pressure | 35 MPa | 35 MPa | 35 MPa | 35 MPa |

| Max Capacity | 8 L/Min | 5 L/Min | 1L/Min | 0.5 L/Min |

| Tip Head Material | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Description

Ultrasonic plant essential oil extraction equipment/extraction machine Principle

l Ultrasound is an effective means to destroy cell structure. This effect can be used to extract substances in cells. For example, starch is extracted from the cell matrix.

l Ultrasound produces alternating high and low pressures in the exposed liquid. During the low-pressure cycle, the ultrasonic generates small vacuum bubbles in the liquid, and the vacuum bubbles violently burst during the high-pressure cycle. This appearance is called cavitation. The implosion of cavitation bubbles causes strong hydrodynamic shear.

l Shear force can decompose fibers and fibrous materials into cell particles and destroy the structure of the cell wall. This releases substances inside the cell, such as starch and sugar, into the liquid. In addition, the cell wall material is broken into small pieces.

l This effect can be used in the fermentation, digestion and other conversion processes of organic matter. After micro-grinding and grinding, ultrasound causes more materials in the cells to be converted, such as starch and cell wall fragments into sugar and enzymes, respectively. It also increases the surface area exposed to enzymes during liquefaction or saccharification. This usually increases the speed and yield of yeast fermentation and other conversion processes, such as increased ethanol production from biomass.

l The cell structure is broken down by ultrasonic (lysis) to extract compounds in the cells of inactivated microorganisms.

l When the liquid is treated with high-intensity ultrasound, the sound waves propagating into the liquid medium will produce alternating high-pressure (compression) and low-pressure (sparse) cycles, the rate of which depends on the frequency. During the low-pressure cycle, high-intensity ultrasound will create small vacuum bubbles or voids in the liquid. When bubbles reach a volume where they can no longer absorb energy, they collapse violently during the high-pressure cycle. This phenomenon is called cavitation. During the explosion, the local area will reach very high temperature (about 5,000K) and pressure (about 2,000atm). The collapse of cavitation bubbles also causes the liquid jet to reach a velocity of up to 280 m/s, and the resulting shear force mechanically destroys the cell membrane and improves material transfer. Depending on the ultrasound parameters used, ultrasound has a destructive or constructive effect on cells, depending on the ultrasound parameters used.

| Frequency | 20Khz | Power | 2000w |

|---|---|---|---|

| Horn Material | Titanium | Horn Size | Customized |

| Generator | Digital | Weight | 15kg |

| Package | Wooden | Warranty | One Year |

| High Light | Titanium Alloy Ultrasonic Extraction Equipment,1000w Ultrasonic Extraction Equipment,20Khz Ultrasonic Extraction Machine | ||

Titanium Alloy 20Khz 1000watt Ultrasonic Extraction Equipment For Plant Essential Oil

20Khz 1000w Ultrasonic extraction equipment for Plant essential oil extraction

Features

Compared with conventional extraction technology, ultrasonic extraction is fast, inexpensive and efficient.

Compared with the water boiling and alcohol precipitation process, ultrasonic extraction has the following outstanding features:

1. No need for high temperature.

2. Atmospheric extraction, good safety, simple operation and convenient maintenance.

3. High extraction efficiency.

4. Has a broad spectrum. Wide applicability, most of the various components of Chinese medicinal materials can be extracted ultrasonically.

5. Ultrasonic extraction has little relationship with the properties of the solvent and the target extract.

6. Reduce energy consumption.

7. The processing capacity of medicinal materials is large, which is doubled or several times higher, and there are few impurities, and the effective ingredients are easy to separate and purify. 8. The extraction process has low cost and significant comprehensive economic benefits.

Parameter

| Model | SONOL20-1000 | SONOL20-500 | SONOL28-300 | SONOL40-100 |

| Frequency | 20±0.5 KHz | 20±0.5 KHz | 28±0.5 KHz | 40±0.5 KHz |

| Power | 1000 W | 500 W | 300 W | 100 W |

| Voltage | 220/110V | 220/110V | 220/110V | 220/110V |

| Temperature | 300 ℃ | 300 ℃ | 300 ℃ | 300 ℃ |

| Pressure | 35 MPa | 35 MPa | 35 MPa | 35 MPa |

| Max Capacity | 8 L/Min | 5 L/Min | 1L/Min | 0.5 L/Min |

| Tip Head Material | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Description

Ultrasonic plant essential oil extraction equipment/extraction machine Principle

l Ultrasound is an effective means to destroy cell structure. This effect can be used to extract substances in cells. For example, starch is extracted from the cell matrix.

l Ultrasound produces alternating high and low pressures in the exposed liquid. During the low-pressure cycle, the ultrasonic generates small vacuum bubbles in the liquid, and the vacuum bubbles violently burst during the high-pressure cycle. This appearance is called cavitation. The implosion of cavitation bubbles causes strong hydrodynamic shear.

l Shear force can decompose fibers and fibrous materials into cell particles and destroy the structure of the cell wall. This releases substances inside the cell, such as starch and sugar, into the liquid. In addition, the cell wall material is broken into small pieces.

l This effect can be used in the fermentation, digestion and other conversion processes of organic matter. After micro-grinding and grinding, ultrasound causes more materials in the cells to be converted, such as starch and cell wall fragments into sugar and enzymes, respectively. It also increases the surface area exposed to enzymes during liquefaction or saccharification. This usually increases the speed and yield of yeast fermentation and other conversion processes, such as increased ethanol production from biomass.

l The cell structure is broken down by ultrasonic (lysis) to extract compounds in the cells of inactivated microorganisms.

l When the liquid is treated with high-intensity ultrasound, the sound waves propagating into the liquid medium will produce alternating high-pressure (compression) and low-pressure (sparse) cycles, the rate of which depends on the frequency. During the low-pressure cycle, high-intensity ultrasound will create small vacuum bubbles or voids in the liquid. When bubbles reach a volume where they can no longer absorb energy, they collapse violently during the high-pressure cycle. This phenomenon is called cavitation. During the explosion, the local area will reach very high temperature (about 5,000K) and pressure (about 2,000atm). The collapse of cavitation bubbles also causes the liquid jet to reach a velocity of up to 280 m/s, and the resulting shear force mechanically destroys the cell membrane and improves material transfer. Depending on the ultrasound parameters used, ultrasound has a destructive or constructive effect on cells, depending on the ultrasound parameters used.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!