loading

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-HC20 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 20Khz | Power | 1000w |

|---|---|---|---|

| Blade Size | 305mm | Blade Material | Titanium |

| Voltage | 220/110V | Weight | 25kg |

| Application | Ultrasonic Food Cutter | Generator | Digital |

| High Light | Ultrasonic Food Cutter 20khz,Hand Press Ultrasonic Food Cutter,Titanium Blades Ultrasonic Cake Cutter | ||

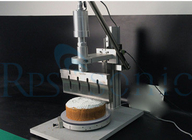

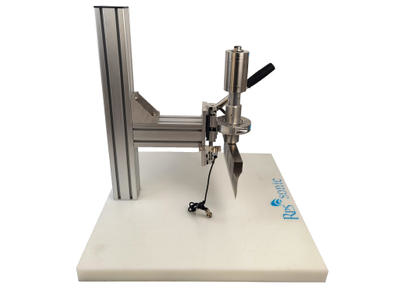

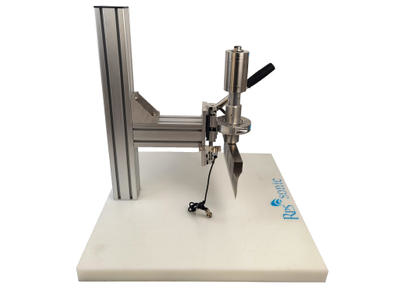

20khz 1000w Hand Press Ultrasonic Food Cutter For Cheese Cake Cutting

20khz 1000w press Ultrasonic Food Cutting Equipment for Bakery Frozen Food

| Machine | Ultrasonic cake Cutter |

| Frequency(KHz) | 20Khz |

| Power | 1000 W |

| Cutting Blade / Horn | Titanium |

| Voltage(V) | 220V |

| The width of blade | depend on your requirement |

| Cutting thickness | 10~20mm(depend on materials) |

| Horn amplitude | 10-40μm |

| Equipment weight | 1KG |

What's the principle of ultrasonic cutting?

Bakery products containing cream or sugary layers, as well as other dough or fat-containing foods, can be cut or trimmed in a controlled way by ultrasound to produce a quality that is visually appealing. The cutting geometries of the tools for longitudinal or cross cuts are individually tailored to product requirements.

As a result of ultrasonic vibrations, only slight product residues remain adhered to the sonotrode, so that to a certain extent, it demonstrates a self-cleaning action.

Because of the ultrasonic vibrations, cutting sonotrodes work with a lower initial pressure than conventional cutters. At the same time, sonotrode wear is less and the cutting quality is considerably better. In addition, the use of ultrasonic cutting systems has a positive effect on the maintenance and down times of the equipment.

The ultrasonic cutter cutter directly loads the ultrasonic energy onto the cutter, and the cutter becomes a cutter with ultrasonic waves. When cutting the material, the material is mainly softened and melted by the ultrasonic energy, and the cutting edge of the cutter only serves as the slit positioning, the ultrasonic energy output, and the separation material. This cutting method is suitable for cutting thick, thick, long, etc. materials that are inconvenient to set the cutting board. Such as raw rubber output from the rubber mixer, pipe cutting, frozen meat, candy, chocolate cutting, printed circuit boards, or hand-held cutting machines.

The basic structure of the ultrasonic cutting board cutter is similar to that of the ultrasonic cutter cutter, except that the ultrasonic output portion is not a cutter but a standard ultrasonic flat mold. Here, the mold is equivalent to a cutting board. However, this is a cutting board that is used for ultrasonic vibration. The cutting knife can still be used in the traditional shape, but the sharpness of the cutting edge is reduced, and the life of the cutting knife is greatly extended.

Pleasing cut and form stability

Product-specific cutting geometries

Cutting sonotrodes with little product adhesion and self-cleaning action

Reduction in maintenance and down times

Products cut almost irrespective of consistency

Cake,Sandwich, biscuit, wafer, nougat

Frozen cakes and pies

Frozen fish

Snack and health bars

Fresh/frozen prepared meats

Dough or baked cookies

Soft and hard cheeses

Fresh/frozen vegetables

Candy and confections

Ice cream bars

| Frequency | 20Khz | Power | 1000w |

|---|---|---|---|

| Blade Size | 305mm | Blade Material | Titanium |

| Voltage | 220/110V | Weight | 25kg |

| Application | Ultrasonic Food Cutter | Generator | Digital |

| High Light | Ultrasonic Food Cutter 20khz,Hand Press Ultrasonic Food Cutter,Titanium Blades Ultrasonic Cake Cutter | ||

20khz 1000w Hand Press Ultrasonic Food Cutter For Cheese Cake Cutting

20khz 1000w press Ultrasonic Food Cutting Equipment for Bakery Frozen Food

| Machine | Ultrasonic cake Cutter |

| Frequency(KHz) | 20Khz |

| Power | 1000 W |

| Cutting Blade / Horn | Titanium |

| Voltage(V) | 220V |

| The width of blade | depend on your requirement |

| Cutting thickness | 10~20mm(depend on materials) |

| Horn amplitude | 10-40μm |

| Equipment weight | 1KG |

What's the principle of ultrasonic cutting?

Bakery products containing cream or sugary layers, as well as other dough or fat-containing foods, can be cut or trimmed in a controlled way by ultrasound to produce a quality that is visually appealing. The cutting geometries of the tools for longitudinal or cross cuts are individually tailored to product requirements.

As a result of ultrasonic vibrations, only slight product residues remain adhered to the sonotrode, so that to a certain extent, it demonstrates a self-cleaning action.

Because of the ultrasonic vibrations, cutting sonotrodes work with a lower initial pressure than conventional cutters. At the same time, sonotrode wear is less and the cutting quality is considerably better. In addition, the use of ultrasonic cutting systems has a positive effect on the maintenance and down times of the equipment.

The ultrasonic cutter cutter directly loads the ultrasonic energy onto the cutter, and the cutter becomes a cutter with ultrasonic waves. When cutting the material, the material is mainly softened and melted by the ultrasonic energy, and the cutting edge of the cutter only serves as the slit positioning, the ultrasonic energy output, and the separation material. This cutting method is suitable for cutting thick, thick, long, etc. materials that are inconvenient to set the cutting board. Such as raw rubber output from the rubber mixer, pipe cutting, frozen meat, candy, chocolate cutting, printed circuit boards, or hand-held cutting machines.

The basic structure of the ultrasonic cutting board cutter is similar to that of the ultrasonic cutter cutter, except that the ultrasonic output portion is not a cutter but a standard ultrasonic flat mold. Here, the mold is equivalent to a cutting board. However, this is a cutting board that is used for ultrasonic vibration. The cutting knife can still be used in the traditional shape, but the sharpness of the cutting edge is reduced, and the life of the cutting knife is greatly extended.

Pleasing cut and form stability

Product-specific cutting geometries

Cutting sonotrodes with little product adhesion and self-cleaning action

Reduction in maintenance and down times

Products cut almost irrespective of consistency

Cake,Sandwich, biscuit, wafer, nougat

Frozen cakes and pies

Frozen fish

Snack and health bars

Fresh/frozen prepared meats

Dough or baked cookies

Soft and hard cheeses

Fresh/frozen vegetables

Candy and confections

Ice cream bars

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!