loading

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-C305 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 20Khz | Power | 1000w |

|---|---|---|---|

| Horn Material | Titanium | Blade Size | 305mm |

| Generator | Digital | Voltage | 220/110V |

| Application | Ultrasonic Food Cutter | Weight | 15kg |

| High Light | 20Khz Ultrasonic Food Cutting Blade,305mm Ultrasonic Cake Cutter,Butter Ultrasonic Cutting Equipment | ||

Parameter

| Machine | Ultrasonic cake Cutter |

| Frequency(KHz) | 20Khz |

| Power | 1000 W |

| Cutting Blade / Horn | Titanium |

| Voltage(V) | 220V |

| The width of blade | depend on your requirement |

| Cutting thickness | 86mm in max |

| Horn amplitude | 10-40μm |

| Equipment weight | 8KG |

Introduction

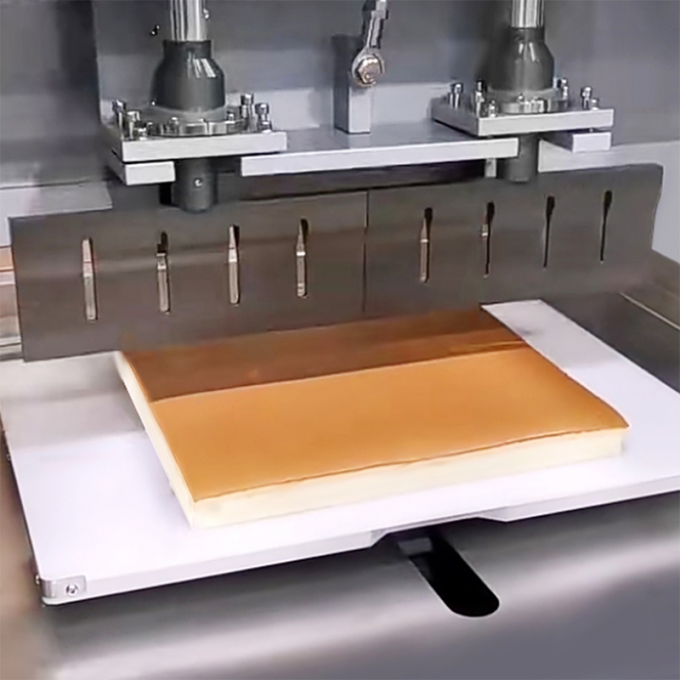

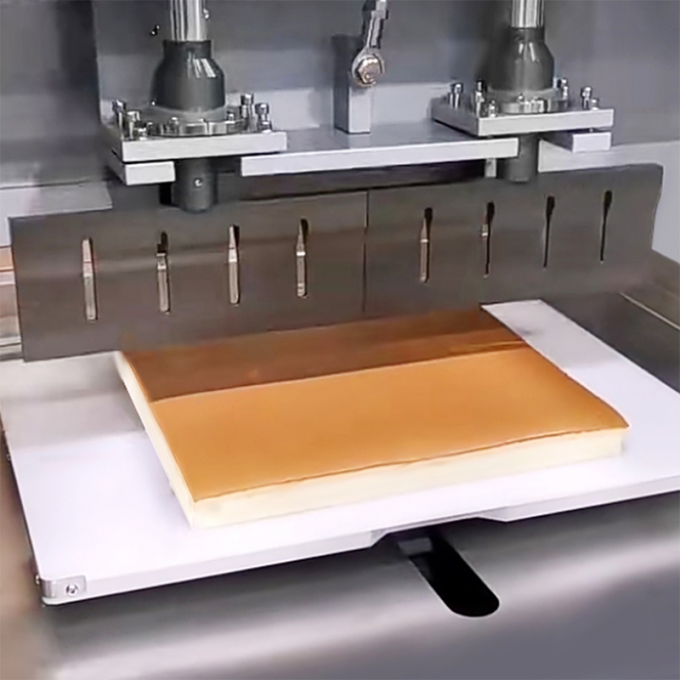

Ultrasonic food cutting is a process utilizing knives that vibrate at high frequency. Applying ultrasonic vibration to a cutting tool creates a nearly frictionless cutting surface which provides many benefits. This low friction cutting surface can slice a multitude of food products cleanly and without smearing.

Ultrasonic food cutting may not be suitable for every food cutting operation. However, high frequency vibration applied to cutting tools does provide significant benefits. Primarily,ultrasonic technology enhances the cut quality and consistency, and offers the ability to cleanly slice multi-textured food products without deformation. RPS-SONIC can evaluate the key factors in your food cutting operation to determine if the low friction cutting surface of an ultrasonic knife might be a fit.

Ultrasonic food cutting is one of RPS-SONIC’s best known solutions. Our ultrasonic cutters for the food industry guarantee clean and precise slicing. All of this without affecting the homogeneity of the food product in any way whether it may be soft or containing fats, sugars, honey, creams and or chocolate, as it is common with desserts and confectionery.

Ultrasonic food cutting systems are commonly employed by dairy product manufacturers to portion hard or mild seasoned cheese that prove to be difficult to slice.

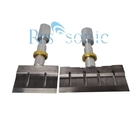

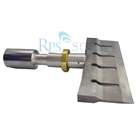

Ultrasonic blades may vary in length and height, depending on clients’ specific requirements. They are made out of titanium and comply with all of CE’s health and organoleptic standards regarding the automation field.

The digital generators that regulate our ultrasonic food cutting machinery offer the possibility to increase, decrease and modify their working parameters: amplitude, power output and time management.

For ultrasonic food cutting applications embedded into automated production lines, we provide vibrating groups with different frequencies ranging from 20, 30 to 40 kHz according to the end user’s requirements, keeping work safety and lack of noise during the manufacturing stage.

Key features

Fast and precise because of unique servo technology

Set your own cutting pattern

For round and rectangular products; both fresh and deep frozen

Product trays up to 400 x 600 mm.

Reliable Safety Light Curtain System

Fast and precise because of unique servo technology

A high quality safety system prevents access of the cutting area during operation

Cut products in or out of the baking trays, blisters and cartons

Advanced software to set product parameters using the icons on the touchscreen

| Frequency | 20Khz | Power | 1000w |

|---|---|---|---|

| Horn Material | Titanium | Blade Size | 305mm |

| Generator | Digital | Voltage | 220/110V |

| Application | Ultrasonic Food Cutter | Weight | 15kg |

| High Light | 20Khz Ultrasonic Food Cutting Blade,305mm Ultrasonic Cake Cutter,Butter Ultrasonic Cutting Equipment | ||

Parameter

| Machine | Ultrasonic cake Cutter |

| Frequency(KHz) | 20Khz |

| Power | 1000 W |

| Cutting Blade / Horn | Titanium |

| Voltage(V) | 220V |

| The width of blade | depend on your requirement |

| Cutting thickness | 86mm in max |

| Horn amplitude | 10-40μm |

| Equipment weight | 8KG |

Introduction

Ultrasonic food cutting is a process utilizing knives that vibrate at high frequency. Applying ultrasonic vibration to a cutting tool creates a nearly frictionless cutting surface which provides many benefits. This low friction cutting surface can slice a multitude of food products cleanly and without smearing.

Ultrasonic food cutting may not be suitable for every food cutting operation. However, high frequency vibration applied to cutting tools does provide significant benefits. Primarily,ultrasonic technology enhances the cut quality and consistency, and offers the ability to cleanly slice multi-textured food products without deformation. RPS-SONIC can evaluate the key factors in your food cutting operation to determine if the low friction cutting surface of an ultrasonic knife might be a fit.

Ultrasonic food cutting is one of RPS-SONIC’s best known solutions. Our ultrasonic cutters for the food industry guarantee clean and precise slicing. All of this without affecting the homogeneity of the food product in any way whether it may be soft or containing fats, sugars, honey, creams and or chocolate, as it is common with desserts and confectionery.

Ultrasonic food cutting systems are commonly employed by dairy product manufacturers to portion hard or mild seasoned cheese that prove to be difficult to slice.

Ultrasonic blades may vary in length and height, depending on clients’ specific requirements. They are made out of titanium and comply with all of CE’s health and organoleptic standards regarding the automation field.

The digital generators that regulate our ultrasonic food cutting machinery offer the possibility to increase, decrease and modify their working parameters: amplitude, power output and time management.

For ultrasonic food cutting applications embedded into automated production lines, we provide vibrating groups with different frequencies ranging from 20, 30 to 40 kHz according to the end user’s requirements, keeping work safety and lack of noise during the manufacturing stage.

Key features

Fast and precise because of unique servo technology

Set your own cutting pattern

For round and rectangular products; both fresh and deep frozen

Product trays up to 400 x 600 mm.

Reliable Safety Light Curtain System

Fast and precise because of unique servo technology

A high quality safety system prevents access of the cutting area during operation

Cut products in or out of the baking trays, blisters and cartons

Advanced software to set product parameters using the icons on the touchscreen

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!