loading

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-C305 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 20Khz | Power | 6000w In Max |

|---|---|---|---|

| Horn Material | Titanium | Blade Size | 305mm |

| Generator | Digital | Voltage | 220/110V |

| Application | Ultrasonic Food Cutter | Weight | 150kg |

| High Light | High Power Ultrasonic Food Cutting Machine,Titanium Blade Ultrasonic Food Cutting Machine,High Power Ultrasonic Cake Cutting Machine | ||

Parameter

| Automatic Ultrasonic Cutting Machine | |

| Dimensions (length) x (width) x (high) | 800*850*1760mm (L x W x H) |

| Weight | 300Kg |

| Rated power | 3kw |

| Cutting speed | 60 knives / min |

| Maximum cut size | Round: up to 12 inches each cake; |

| Rectangle: up to 600 x 450 mm | |

| Maximum products depth | 120mm |

| Number of cutting knives | 3 |

| Cutting knife size | 255mm |

| Whether it can be rotated | Cutting plateform rotated |

| Cut type | Round, sliced, rectangular |

| Conveyor belt (several) | No |

| Rack structure | Stainless steel |

| Safety protection system | Safety protection grating |

| Screen | 7 inch touch screen |

| Control cabinet | Built-in |

| Control System | Multi-axis Control System |

| Cutting knife control system | Servo motor |

| Electric supply | Single phase, 220v, 50-60Hz |

| Compressed air connection | 0.4Mpa |

| Product into and out of material | Manually |

| Machine mobility | Pully |

| Can be controlled by touch screen | Yes |

Introduction

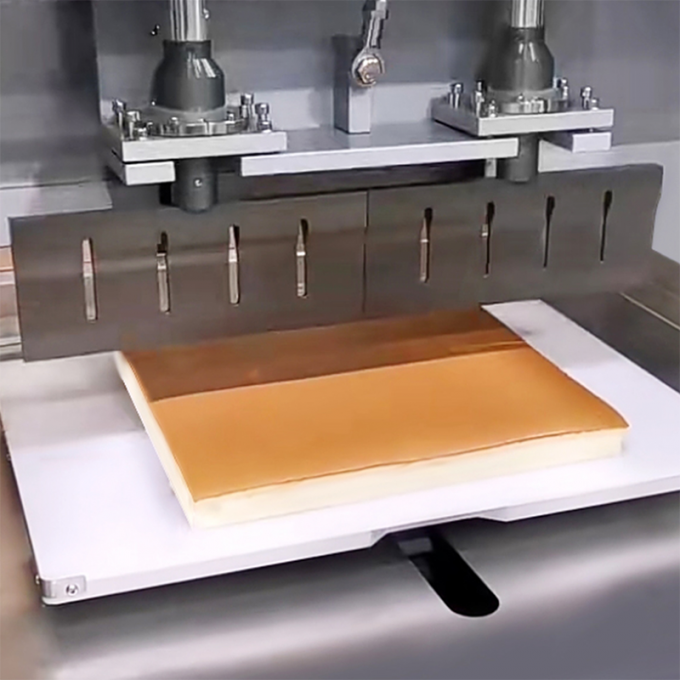

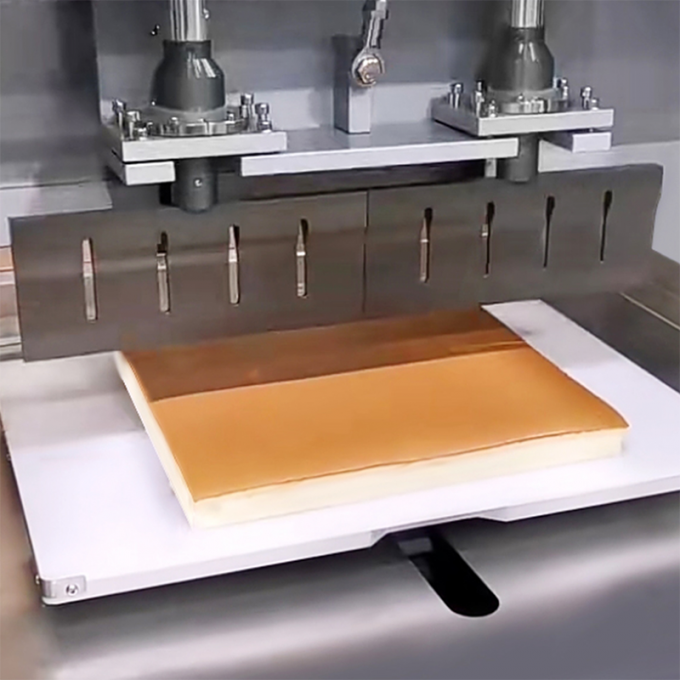

A knife blade vibrating at an ultrasonic frequency can easily slice into the material, cutting it precisely without producing any waste. The manufacturing of nonwovens and wovens, in particular for filters, must be economical and process-safe. With our ultrasonic technology, we are able to separate accurately and quickly, and weld edges in an aesthetical and reliable way. Sonotrodes and anvils especially designed for this kind of application enable us to achieve almost any type of form. Our customers from the medical technology, cosmetics, cleaning and engineering industry appreciate this a lot.

Uses high frequency wave vibration to quickly process food, eliminating the traditional cutting blade continuous cleaning caused by downtime. Ultrasonic food cutting machine provide a new approach to cutting, slicing, and automatically turning to handle a variety of foods, making the production process, waste minimization and maintenance costs the lowest.

Ultrasonic food cutting equipment is the use of ultrasonic energy generated 20,000 times per second high-frequency vibration between the blade and food to establish a surface almost no friction, so eliminate sticky knives and squeezing and other issues.

Features

1. The blade is easy to clean, hence no cut material remains attached to it

2. Reduction of outage time due to cleaning

3. Cutting without pressure prevents any deformation of the material

4. High cut quality, no smudging and no breaking of individual layers

5. Processing time can be reduced

6. No heat input into the product - the tool remains cold

Working Principle

A knife edge vibrating with ultrasound makes a fast and precise cut with minimum resistance and without releasing particles. Ultrasound has been used for the cutting of finished products for many years. When cutting bakery products, energy bars, cheese, pizza etc. the vibrating (cold) cutting sonotrode reduces the resistance in the cutting process and also cleans itself of any product remains attached. The result: smooth, reproducible cut faces without deformations and thermal damage to the products.

Applications

*1. It can be widely used in bakery products such as sliced cream multi-layer cake, sandwich mousse cake, jujube cake, steamed sandwich cake, Napoleon, Swiss roll, brownie, tiramisu, cheese, ham sandwich sandwich.

*2. Can be divided into various shapes of baked goods and frozen food, such as round, square, fan-shaped, triangular and so on.

*3. Can be customized according to customer special needs and existing conditions of the ultrasonic solution, welcome to sample test.

| Frequency | 20Khz | Power | 6000w In Max |

|---|---|---|---|

| Horn Material | Titanium | Blade Size | 305mm |

| Generator | Digital | Voltage | 220/110V |

| Application | Ultrasonic Food Cutter | Weight | 150kg |

| High Light | High Power Ultrasonic Food Cutting Machine,Titanium Blade Ultrasonic Food Cutting Machine,High Power Ultrasonic Cake Cutting Machine | ||

Parameter

| Automatic Ultrasonic Cutting Machine | |

| Dimensions (length) x (width) x (high) | 800*850*1760mm (L x W x H) |

| Weight | 300Kg |

| Rated power | 3kw |

| Cutting speed | 60 knives / min |

| Maximum cut size | Round: up to 12 inches each cake; |

| Rectangle: up to 600 x 450 mm | |

| Maximum products depth | 120mm |

| Number of cutting knives | 3 |

| Cutting knife size | 255mm |

| Whether it can be rotated | Cutting plateform rotated |

| Cut type | Round, sliced, rectangular |

| Conveyor belt (several) | No |

| Rack structure | Stainless steel |

| Safety protection system | Safety protection grating |

| Screen | 7 inch touch screen |

| Control cabinet | Built-in |

| Control System | Multi-axis Control System |

| Cutting knife control system | Servo motor |

| Electric supply | Single phase, 220v, 50-60Hz |

| Compressed air connection | 0.4Mpa |

| Product into and out of material | Manually |

| Machine mobility | Pully |

| Can be controlled by touch screen | Yes |

Introduction

A knife blade vibrating at an ultrasonic frequency can easily slice into the material, cutting it precisely without producing any waste. The manufacturing of nonwovens and wovens, in particular for filters, must be economical and process-safe. With our ultrasonic technology, we are able to separate accurately and quickly, and weld edges in an aesthetical and reliable way. Sonotrodes and anvils especially designed for this kind of application enable us to achieve almost any type of form. Our customers from the medical technology, cosmetics, cleaning and engineering industry appreciate this a lot.

Uses high frequency wave vibration to quickly process food, eliminating the traditional cutting blade continuous cleaning caused by downtime. Ultrasonic food cutting machine provide a new approach to cutting, slicing, and automatically turning to handle a variety of foods, making the production process, waste minimization and maintenance costs the lowest.

Ultrasonic food cutting equipment is the use of ultrasonic energy generated 20,000 times per second high-frequency vibration between the blade and food to establish a surface almost no friction, so eliminate sticky knives and squeezing and other issues.

Features

1. The blade is easy to clean, hence no cut material remains attached to it

2. Reduction of outage time due to cleaning

3. Cutting without pressure prevents any deformation of the material

4. High cut quality, no smudging and no breaking of individual layers

5. Processing time can be reduced

6. No heat input into the product - the tool remains cold

Working Principle

A knife edge vibrating with ultrasound makes a fast and precise cut with minimum resistance and without releasing particles. Ultrasound has been used for the cutting of finished products for many years. When cutting bakery products, energy bars, cheese, pizza etc. the vibrating (cold) cutting sonotrode reduces the resistance in the cutting process and also cleans itself of any product remains attached. The result: smooth, reproducible cut faces without deformations and thermal damage to the products.

Applications

*1. It can be widely used in bakery products such as sliced cream multi-layer cake, sandwich mousse cake, jujube cake, steamed sandwich cake, Napoleon, Swiss roll, brownie, tiramisu, cheese, ham sandwich sandwich.

*2. Can be divided into various shapes of baked goods and frozen food, such as round, square, fan-shaped, triangular and so on.

*3. Can be customized according to customer special needs and existing conditions of the ultrasonic solution, welcome to sample test.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!