loading

| Availability: | |

|---|---|

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-SONO20-3 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

20Khz 9000w indudtrial Continuous ultrasonic Sonicator Processor Homogenizer Emulsifier

Parameter

| Model | SONO20-1000 | SONO20-2000 | SONO15-3000 | SONO20-3000 |

| Frequency | 20±0.5 KHz | 20±0.5 KHz | 15±0.5 KHz | 20±0.5 KHz |

| Power | 1000 W | 2000 W | 3000 W | 3000 W |

| Voltage | 220/110V | 220/110V | 220/110V | 220/110V |

| Temperature | 300 ℃ | 300 ℃ | 300 ℃ | 300 ℃ |

| Pressure | 35 MPa | 35 MPa | 35 MPa | 35 MPa |

| Intensity of sound | 20 W/cm² | 40 W/cm² | 60 W/cm² | 60 W/cm² |

| Max Capacity | 10 L/Min | 15 L/Min | 20 L/Min | 20 L/Min |

| Tip Head Material | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Description

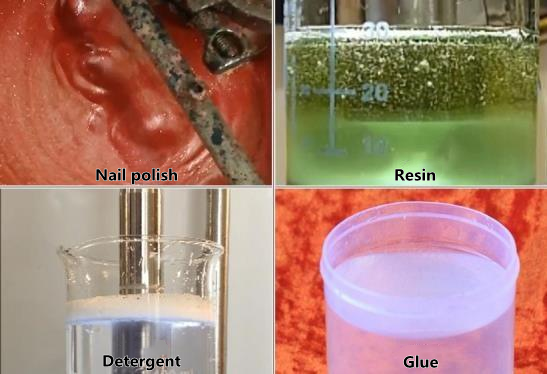

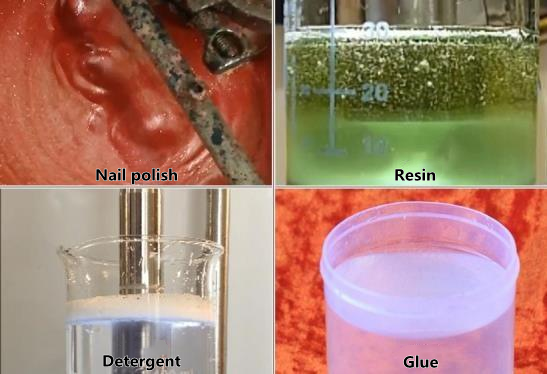

Ultrasonic emulsification production line

It can also be called production ultrasonic emulsification machine, circulating multi-stage ultrasonic emulsification machine, large ultrasonic emulsification equipment. It consists of ultrasonic emission system, ultrasonic numerical control power supply, ultrasonic control system assembly, ultrasonic reactor assembly, frame and pipeline accessories. Generally used for mass production on the production line, the annual output (8h/day) can reach 10 tons to 300 tons. The rated power of ultrasonic single set is 3000W/set, and the conventional production line is three-in-one. In addition, according to the on-site working conditions, an applicable plan can be formulated.

Ultrasonic traditional drug extraction is also called ultrasonic assisted extraction, ultrasonic extraction, ultrasonic traditional Chinese medicine extraction machine. Mainly through the rapid mechanical vibration wave generated by the piezoelectric transducer to reduce the force between the target extract and the sample matrix to achieve solid-liquid, liquid-liquid extraction separation.

Ultrasonic extraction is mainly suitable for various processes such as normal pressure and normal temperature ultrasonic extraction, Soxhlet extraction, dynamic heat reflux extraction, plant essential oil extraction and vacuum concentration of extracts in traditional Chinese medicine, health care products, biopharmaceuticals, cosmetics, food and other industries. Ultrasonic traditional Chinese medicine extraction/extraction equipment has a single extraction rate as high as 95%. Wide applicability and high cost performance. It is very suitable for universities, research institutes, laboratories of enterprises and institutions, and R&D departments of pharmaceutical factories for multi-variety, small-batch testing and mass production.

Ultrasonic sewage wastewater treatment: used for domestic sewage wastewater, printing and dyeing sewage and other treatment. Acting on the final process of biodegradation, the microorganisms in the sewage are broken through ultrasonic cavitation, which can improve the filtration efficiency of sewage treatment and greatly reduce the water content of the sludge after filtration.

Ultrasonic battery slurry dispersion and lithium battery slurry dispersion are stirred due to the instantaneous acoustic cavitation effect of ultrasonic waves. Ultrasonic stirring can achieve the same effect as stirring based on hydrodynamic technology. Ultrasonic agitation by ultrasonic technology is particularly advantageous for battery slurry preparation.

By using ultrasonic technology, ultrasonic lithium battery slurry dispersion can not only reduce battery production costs, but also improve battery capacity and cycle stability.

The preparation of lithium battery slurry includes a series of processes such as mixing, dissolving, and dispersing between liquid and liquid, liquid and solid materials, and this process is accompanied by changes in temperature, viscosity, and environment. The mixing and dispersion of lithium battery slurry is always accompanied by the whole process of lithium battery slurry preparation.

20Khz 9000w indudtrial Continuous ultrasonic Sonicator Processor Homogenizer Emulsifier

Parameter

| Model | SONO20-1000 | SONO20-2000 | SONO15-3000 | SONO20-3000 |

| Frequency | 20±0.5 KHz | 20±0.5 KHz | 15±0.5 KHz | 20±0.5 KHz |

| Power | 1000 W | 2000 W | 3000 W | 3000 W |

| Voltage | 220/110V | 220/110V | 220/110V | 220/110V |

| Temperature | 300 ℃ | 300 ℃ | 300 ℃ | 300 ℃ |

| Pressure | 35 MPa | 35 MPa | 35 MPa | 35 MPa |

| Intensity of sound | 20 W/cm² | 40 W/cm² | 60 W/cm² | 60 W/cm² |

| Max Capacity | 10 L/Min | 15 L/Min | 20 L/Min | 20 L/Min |

| Tip Head Material | Titanium Alloy | Titanium Alloy | Titanium Alloy | Titanium Alloy |

Description

Ultrasonic emulsification production line

It can also be called production ultrasonic emulsification machine, circulating multi-stage ultrasonic emulsification machine, large ultrasonic emulsification equipment. It consists of ultrasonic emission system, ultrasonic numerical control power supply, ultrasonic control system assembly, ultrasonic reactor assembly, frame and pipeline accessories. Generally used for mass production on the production line, the annual output (8h/day) can reach 10 tons to 300 tons. The rated power of ultrasonic single set is 3000W/set, and the conventional production line is three-in-one. In addition, according to the on-site working conditions, an applicable plan can be formulated.

Ultrasonic traditional drug extraction is also called ultrasonic assisted extraction, ultrasonic extraction, ultrasonic traditional Chinese medicine extraction machine. Mainly through the rapid mechanical vibration wave generated by the piezoelectric transducer to reduce the force between the target extract and the sample matrix to achieve solid-liquid, liquid-liquid extraction separation.

Ultrasonic extraction is mainly suitable for various processes such as normal pressure and normal temperature ultrasonic extraction, Soxhlet extraction, dynamic heat reflux extraction, plant essential oil extraction and vacuum concentration of extracts in traditional Chinese medicine, health care products, biopharmaceuticals, cosmetics, food and other industries. Ultrasonic traditional Chinese medicine extraction/extraction equipment has a single extraction rate as high as 95%. Wide applicability and high cost performance. It is very suitable for universities, research institutes, laboratories of enterprises and institutions, and R&D departments of pharmaceutical factories for multi-variety, small-batch testing and mass production.

Ultrasonic sewage wastewater treatment: used for domestic sewage wastewater, printing and dyeing sewage and other treatment. Acting on the final process of biodegradation, the microorganisms in the sewage are broken through ultrasonic cavitation, which can improve the filtration efficiency of sewage treatment and greatly reduce the water content of the sludge after filtration.

Ultrasonic battery slurry dispersion and lithium battery slurry dispersion are stirred due to the instantaneous acoustic cavitation effect of ultrasonic waves. Ultrasonic stirring can achieve the same effect as stirring based on hydrodynamic technology. Ultrasonic agitation by ultrasonic technology is particularly advantageous for battery slurry preparation.

By using ultrasonic technology, ultrasonic lithium battery slurry dispersion can not only reduce battery production costs, but also improve battery capacity and cycle stability.

The preparation of lithium battery slurry includes a series of processes such as mixing, dissolving, and dispersing between liquid and liquid, liquid and solid materials, and this process is accompanied by changes in temperature, viscosity, and environment. The mixing and dispersion of lithium battery slurry is always accompanied by the whole process of lithium battery slurry preparation.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!