loading

| Availability: | |

|---|---|

| Quantity: | |

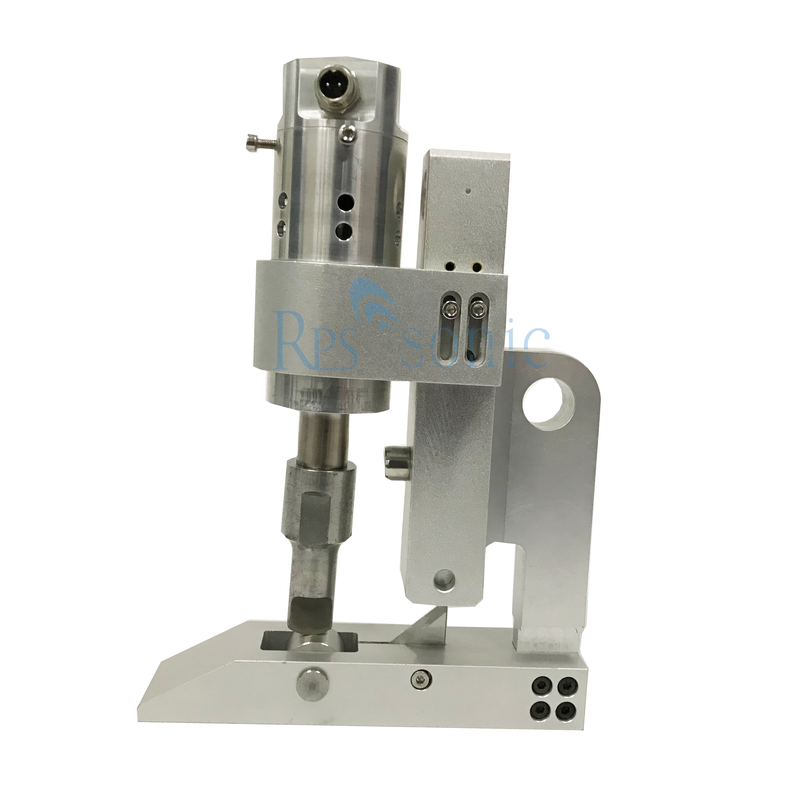

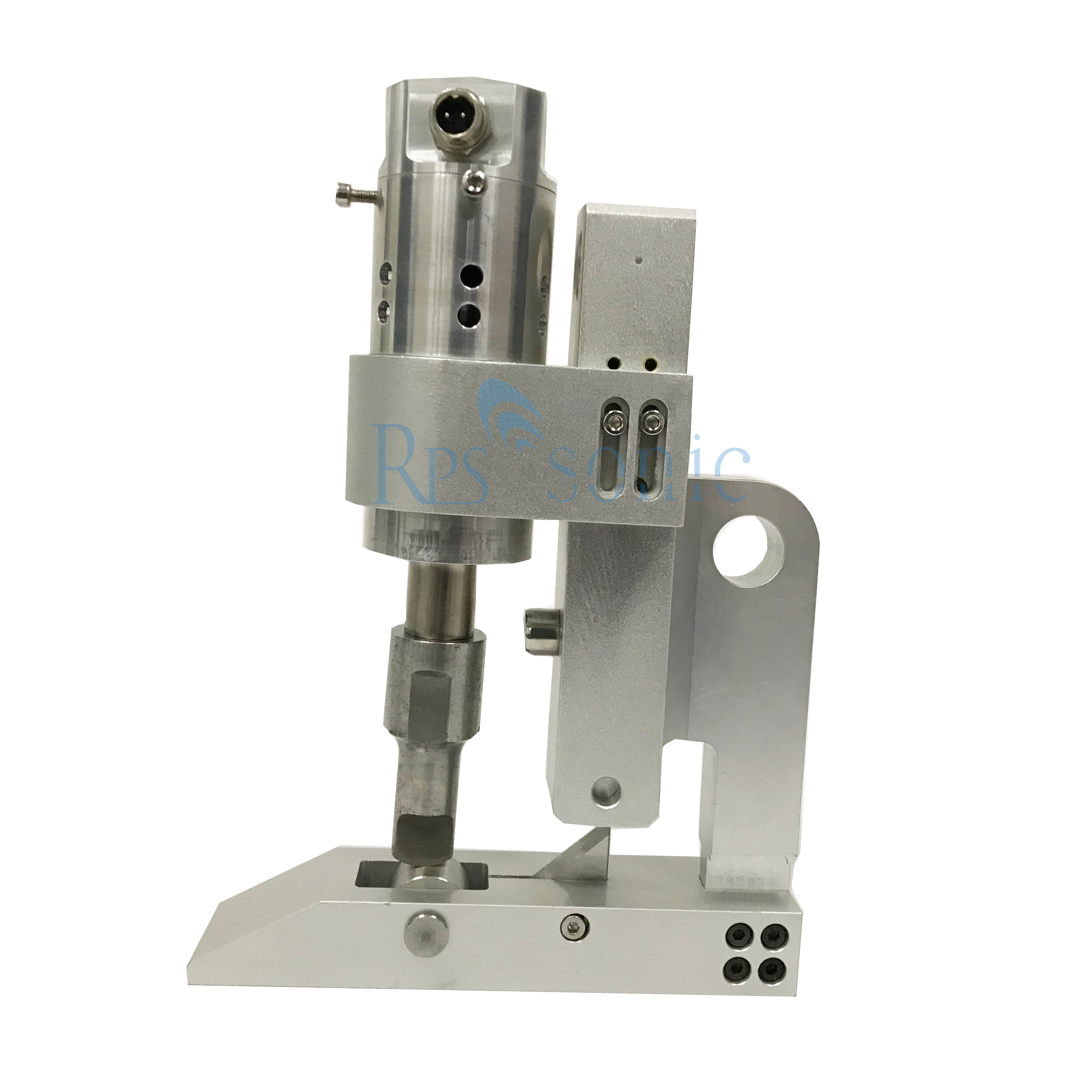

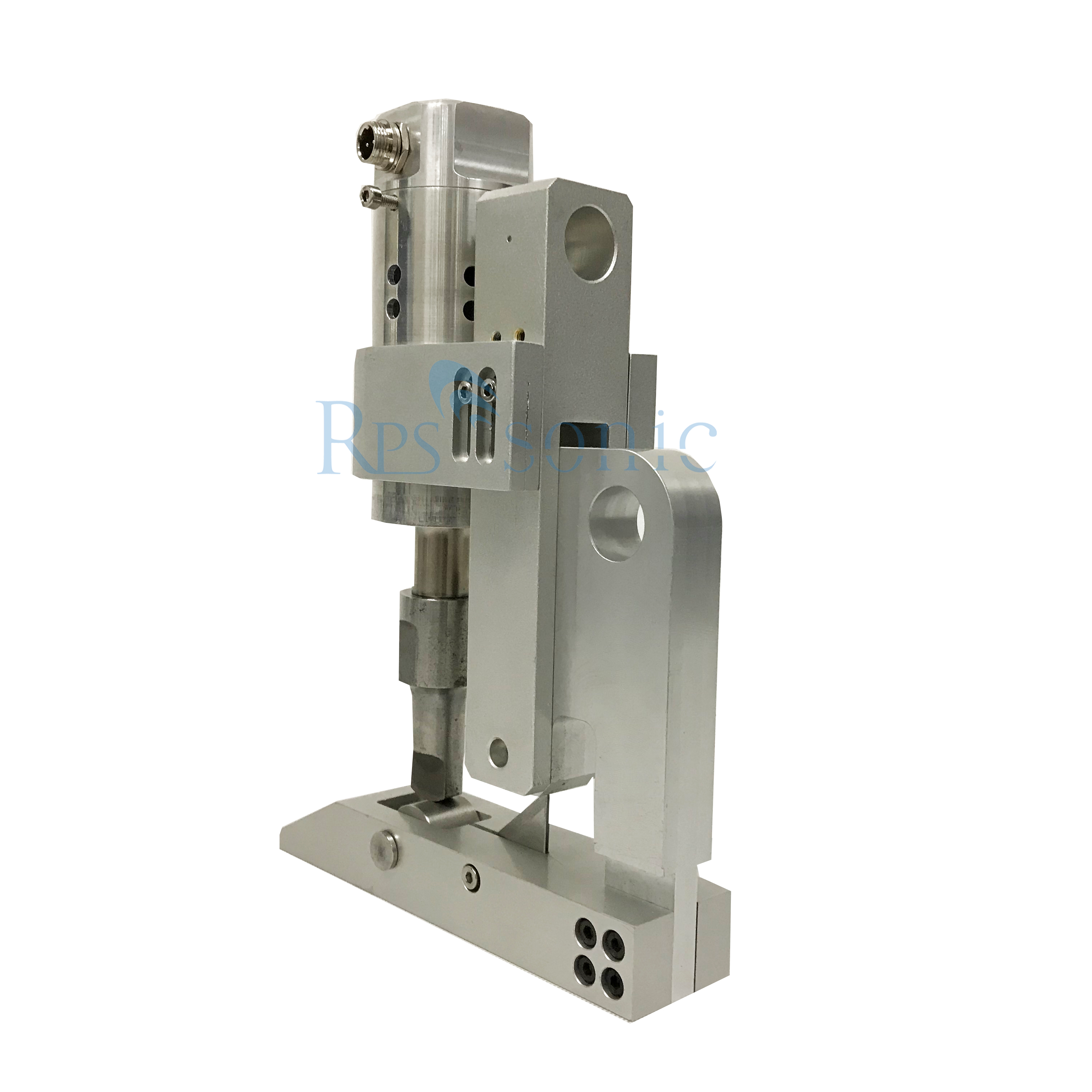

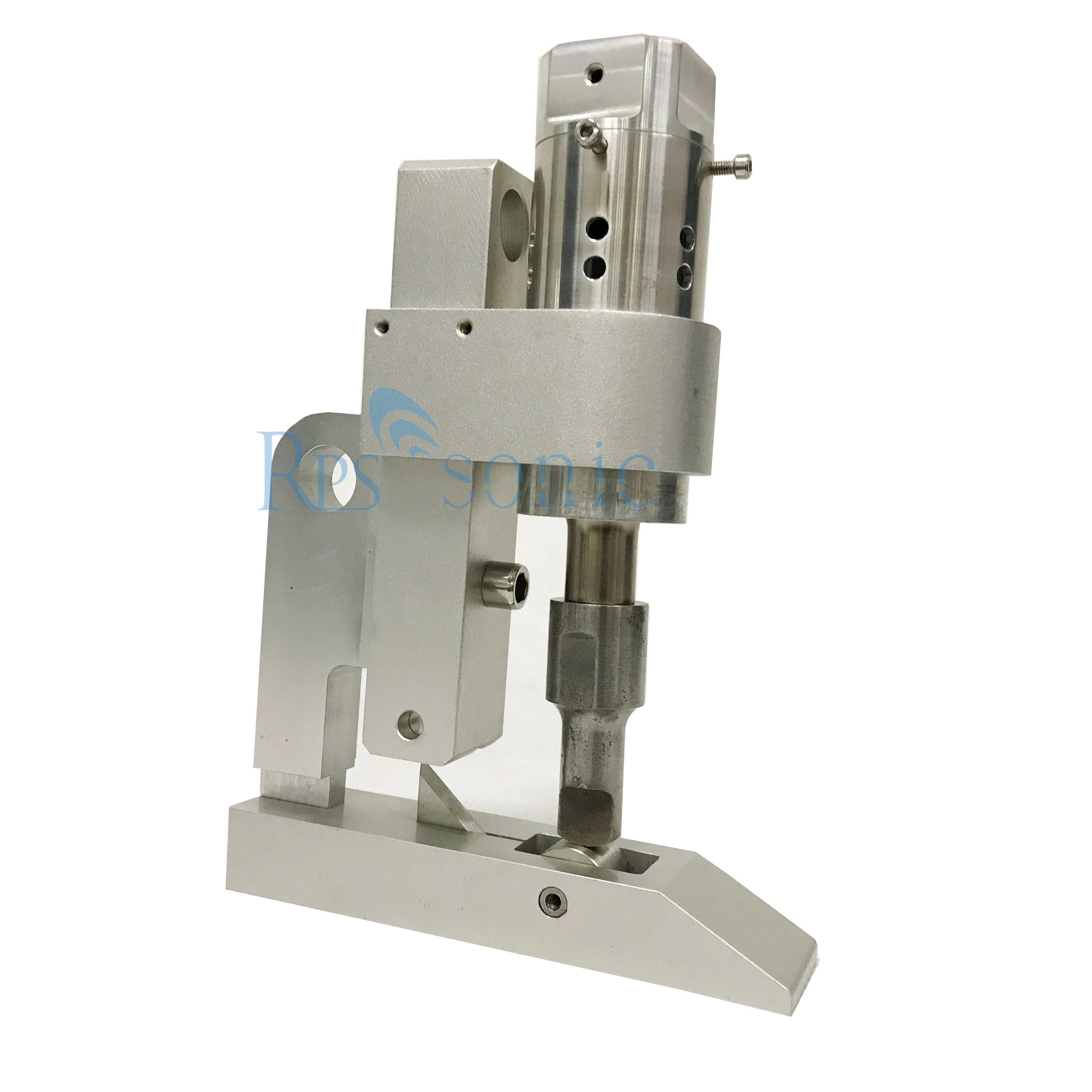

RPS-FC35

RPS-SONIC

| Place of Origin | CHINA |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-S40 |

| Minimum Order Quantity | 1SET |

| Price | Negotiation |

| Packaging Details | FOAM AND CARTON |

| Delivery Time | 3DAYS after Payment |

| Payment Terms | T/T, Western Union, MoneyGram, PAYPAL |

| Supply Ability | 500 SETS PER MONTH |

| Name | Ultrasonic Slicing Machine | Frequency | 35Khz |

|---|---|---|---|

| Power | 500w | Type | Light Al |

| Cutting Material | TEXTILE FABRIC | Blade | Easy Replace |

| High Light | 20khz ultrasonic fabric cutting machine,20khz ultrasonic fabric cutter,500w ultrasonic fabric cutting machine | ||

Ultrasonic Cutting Machine is a class of device using ultrasonic energy for cutting. Instead of using traditional blade cutting, ultrasonic cutting has its advantages of smooth, reliable cutting, accurate trimming, no deformation, no raising, fuzzing, spinning, wrinkling etc. It can avoid the rough cutting-edge, coked edge, fuzzballs and other shortcomings of laser cutting machine.

Ultrasonic cutting machine is used for cutting rubber, synthetic fabric, cloth, plastic, sheet metal, food etc.

The cutting of food products using ultrasound is performed when an ultrasonic blade comes into contact with the product to be cut, the high vibration of 40,000 pulses per second, makes this product very easily be cut even if it is of delicate or sticky texture composition. The much higher vibration does not allow any product to stick to the blade. The cut is clean and without pressure on the product.

Environment-friendly (No noise, no smoke, no air contamination)

Smooth cutting of difficult-to-cut materials

Small hand-held size(can be attached to automotive machinery arms)

No special installation equipmen

Curtains are an important functional interior decoration.

Curtain color patterns, material style, exquisite texture is an important factor affecting the indoor visual and comfort.

Ultrasonic Curtain Cutting Machine

For people’s high pursuit, manufacturers pay more and more attention to the curtains of the production process. Cutting as the first step in curtain processing, which has a significant impact on the subsequent depth processing.

Ultrasonic Curtain Cutting Machine

Cutting fabric is a key part of the slitting machine. CHEERSONIC ultrasonic fabric cutting equipment is mainly used for cutting a wide range of fabric materials into a variety of narrow fabric materials, slitting process, including unwinding and rewinding two processes.

The energy of the ultrasonic wave instantaneously opens the molecular chain of the treated fabric, the cutting strength is greatly reduced, and the purpose of cutting the fabric can be achieved by only applying a small force.

Ultrasonic Curtain Cutting Machine

Ultrasonic fabric cutting equipment for cutting curtains of various materials, such as printed cloth, dyed cloth, yarn-dyed cloth, jacquard cloth, cotton, linen, polyester, silk and so on.

Advantage: Slitting beautiful, solid, not scattered edge, no flash edge, without preheating, high efficiency, no black, no coke, incision soft, beautiful flat and so on.

| Frequency | 35Khz |

|---|---|

| Frequency adjustment | Auto-tracking type |

| Max. power output | 500W |

| Power output | Infinitive adjustment |

| Power supply | AC200V 50/60Hz |

| Electricity consumption | 1000VA |

| Outer dimension (mm) | 120*120*380 |

| External control | on/off, Emergency stop, Change of output |

| Weight | 8kg |

| Blade thickness | 0.6mm |

Components:

One complete ultrasonic sealing head, steel or titanium alloy, 40Khz transducer, with fan-cooled, ceramic cutting blade, engraved wheel, mechanical slitting device;

One digital generator, adjust the amplitude between 50-100%;

3 cables, supply, ultrasonic, machine and head connection to operate remote controls, overload, amplitude piloting.

The synthetic fabrics that work best with ultrasonic cutting machinery are those that contain thermoplastics with similar melting temperatures and compatible molecular structures. In order for the ultrasonic cutting to work properly, synthetic fabrics should all share the following characteristics:

– Wide melting range

– High friction coefficient

– Uniform thickness

– At least 25 % of thermoplastic contents

– Enough stiffness and thickness to take the energy on the material’s interface (0,32258 mm / 0,0127 mm minimum).

Polyester is considered to be the most suitable synthetic material to be subjected to ultrasonic applications. Moreover, ultrasounds can generate strong and long-lasting seams in synthetic elements like Nylon 6 and Nylon 6/6 as well. Most polyolefins (polypropylene and polyethylene), on the other hand, show excellent welding characteristics, plus they are very lightweight. This makes them to lend themselves to various industrial uses.

Industry Segmentation

Cloth Cutting

Leather Cutting

Synthetic Fiber Cutting

Cotton Cutting

| Name | Ultrasonic Slicing Machine | Frequency | 35Khz |

|---|---|---|---|

| Power | 500w | Type | Light Al |

| Cutting Material | TEXTILE FABRIC | Blade | Easy Replace |

| High Light | 20khz ultrasonic fabric cutting machine,20khz ultrasonic fabric cutter,500w ultrasonic fabric cutting machine | ||

Ultrasonic Cutting Machine is a class of device using ultrasonic energy for cutting. Instead of using traditional blade cutting, ultrasonic cutting has its advantages of smooth, reliable cutting, accurate trimming, no deformation, no raising, fuzzing, spinning, wrinkling etc. It can avoid the rough cutting-edge, coked edge, fuzzballs and other shortcomings of laser cutting machine.

Ultrasonic cutting machine is used for cutting rubber, synthetic fabric, cloth, plastic, sheet metal, food etc.

The cutting of food products using ultrasound is performed when an ultrasonic blade comes into contact with the product to be cut, the high vibration of 40,000 pulses per second, makes this product very easily be cut even if it is of delicate or sticky texture composition. The much higher vibration does not allow any product to stick to the blade. The cut is clean and without pressure on the product.

Environment-friendly (No noise, no smoke, no air contamination)

Smooth cutting of difficult-to-cut materials

Small hand-held size(can be attached to automotive machinery arms)

No special installation equipmen

Curtains are an important functional interior decoration.

Curtain color patterns, material style, exquisite texture is an important factor affecting the indoor visual and comfort.

Ultrasonic Curtain Cutting Machine

For people’s high pursuit, manufacturers pay more and more attention to the curtains of the production process. Cutting as the first step in curtain processing, which has a significant impact on the subsequent depth processing.

Ultrasonic Curtain Cutting Machine

Cutting fabric is a key part of the slitting machine. CHEERSONIC ultrasonic fabric cutting equipment is mainly used for cutting a wide range of fabric materials into a variety of narrow fabric materials, slitting process, including unwinding and rewinding two processes.

The energy of the ultrasonic wave instantaneously opens the molecular chain of the treated fabric, the cutting strength is greatly reduced, and the purpose of cutting the fabric can be achieved by only applying a small force.

Ultrasonic Curtain Cutting Machine

Ultrasonic fabric cutting equipment for cutting curtains of various materials, such as printed cloth, dyed cloth, yarn-dyed cloth, jacquard cloth, cotton, linen, polyester, silk and so on.

Advantage: Slitting beautiful, solid, not scattered edge, no flash edge, without preheating, high efficiency, no black, no coke, incision soft, beautiful flat and so on.

| Frequency | 35Khz |

|---|---|

| Frequency adjustment | Auto-tracking type |

| Max. power output | 500W |

| Power output | Infinitive adjustment |

| Power supply | AC200V 50/60Hz |

| Electricity consumption | 1000VA |

| Outer dimension (mm) | 120*120*380 |

| External control | on/off, Emergency stop, Change of output |

| Weight | 8kg |

| Blade thickness | 0.6mm |

Components:

One complete ultrasonic sealing head, steel or titanium alloy, 40Khz transducer, with fan-cooled, ceramic cutting blade, engraved wheel, mechanical slitting device;

One digital generator, adjust the amplitude between 50-100%;

3 cables, supply, ultrasonic, machine and head connection to operate remote controls, overload, amplitude piloting.

The synthetic fabrics that work best with ultrasonic cutting machinery are those that contain thermoplastics with similar melting temperatures and compatible molecular structures. In order for the ultrasonic cutting to work properly, synthetic fabrics should all share the following characteristics:

– Wide melting range

– High friction coefficient

– Uniform thickness

– At least 25 % of thermoplastic contents

– Enough stiffness and thickness to take the energy on the material’s interface (0,32258 mm / 0,0127 mm minimum).

Polyester is considered to be the most suitable synthetic material to be subjected to ultrasonic applications. Moreover, ultrasounds can generate strong and long-lasting seams in synthetic elements like Nylon 6 and Nylon 6/6 as well. Most polyolefins (polypropylene and polyethylene), on the other hand, show excellent welding characteristics, plus they are very lightweight. This makes them to lend themselves to various industrial uses.

Industry Segmentation

Cloth Cutting

Leather Cutting

Synthetic Fiber Cutting

Cotton Cutting

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!