loading

| Availability: | |

|---|---|

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-W20 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

Description

When the ultrasonic welding machine is turned on, it automatically searches for the resonant frequency of the vibrator and welding head, detects the system power supply, the welding head frequency range, and whether the button fails. Confirm the working frequency point and store the memory. Determine whether the welding head current is too high. After confirming that it is normal, the start button lock of each part will be automatically released, otherwise the equipment cannot start normally.

Function

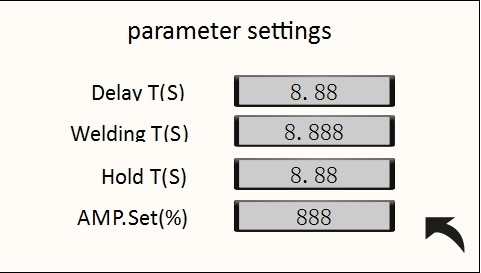

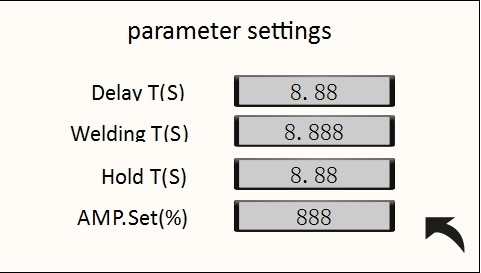

Real-time frequency automatic tracking display;

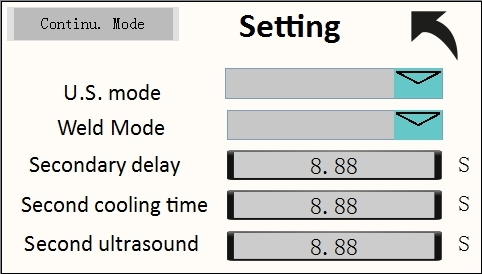

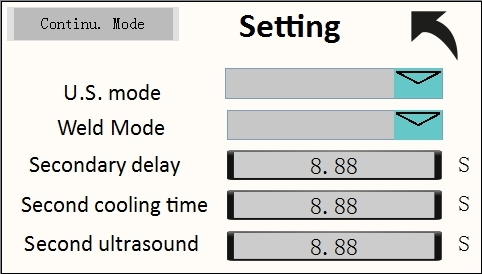

Welding mode: time, energy

Amplitude stepping function;

Welding amplitude 10-100 adjustable (1% accuracy)

Amplitude compensation

Mold impedance analysis + protection

Overload protection;

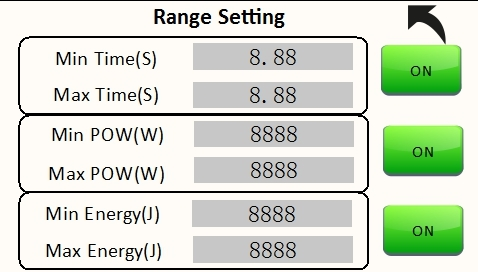

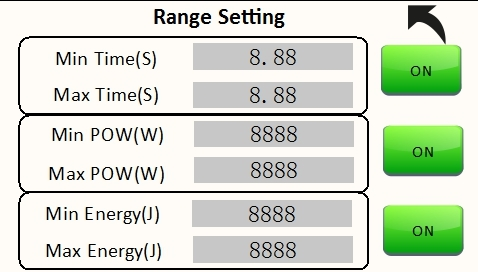

Quality management (time, energy mutual detection)

welding record (operation statistics);

powerful, high quality, high welding stability

What is an ultrasonic welder?

Ultrasonic welding (USW) is a solid-state welding process that produces a weld by local application of high-frequency vibratory energy while the work pieces are held together under pressure. 5. A sound metallurgical bond is produced without melting the base material.

How does ultrasonic welding machine work?

The vibrations, produced by a welding sonotrode or horn, as it is generally known, are used to soften or melt the thermoplastic material at the joint line. The components to be joined are held together under pressure and subjected to vibrations, usually at a frequency of 20 or 40 kHz.

Where is ultrasonic welding used?

Ultrasonic welding is used in almost all major industries like automotive, electronic and appliances, medical, packaging etc. A limitation of ultrasonic welding is that with current technology, large joints cannot be welded in a single operation. In addition, specifically designed joint details are required.

Parameter

| Frequency | Power | Working distance | Input voltage | Air pressure | System language |

| 15Khz | 2500W/3000W/4000W | 75mm/100mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 20Khz | 2000W/3000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 30Khz | 1000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 35Khz | 1000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 40Khz | 800W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

Service and shipment

l Warranty one year for transducer.

l You can contact us for technical inquiry any time.

l We supply OEM service for oversea customer, also will keep Confidentiality for our customers.

l We supply customized products service for small quantity also.

l Shipment by FED-EX /DHL

Description

When the ultrasonic welding machine is turned on, it automatically searches for the resonant frequency of the vibrator and welding head, detects the system power supply, the welding head frequency range, and whether the button fails. Confirm the working frequency point and store the memory. Determine whether the welding head current is too high. After confirming that it is normal, the start button lock of each part will be automatically released, otherwise the equipment cannot start normally.

Function

Real-time frequency automatic tracking display;

Welding mode: time, energy

Amplitude stepping function;

Welding amplitude 10-100 adjustable (1% accuracy)

Amplitude compensation

Mold impedance analysis + protection

Overload protection;

Quality management (time, energy mutual detection)

welding record (operation statistics);

powerful, high quality, high welding stability

What is an ultrasonic welder?

Ultrasonic welding (USW) is a solid-state welding process that produces a weld by local application of high-frequency vibratory energy while the work pieces are held together under pressure. 5. A sound metallurgical bond is produced without melting the base material.

How does ultrasonic welding machine work?

The vibrations, produced by a welding sonotrode or horn, as it is generally known, are used to soften or melt the thermoplastic material at the joint line. The components to be joined are held together under pressure and subjected to vibrations, usually at a frequency of 20 or 40 kHz.

Where is ultrasonic welding used?

Ultrasonic welding is used in almost all major industries like automotive, electronic and appliances, medical, packaging etc. A limitation of ultrasonic welding is that with current technology, large joints cannot be welded in a single operation. In addition, specifically designed joint details are required.

Parameter

| Frequency | Power | Working distance | Input voltage | Air pressure | System language |

| 15Khz | 2500W/3000W/4000W | 75mm/100mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 20Khz | 2000W/3000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 30Khz | 1000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 35Khz | 1000W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

| 40Khz | 800W | 75mm | 220V or 110v | 0.2-0.8Mpa | English/Chinese |

Service and shipment

l Warranty one year for transducer.

l You can contact us for technical inquiry any time.

l We supply OEM service for oversea customer, also will keep Confidentiality for our customers.

l We supply customized products service for small quantity also.

l Shipment by FED-EX /DHL

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment