loading

| Availability: | |

|---|---|

| Quantity: | |

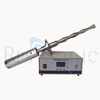

RPS-SONO20

RPS-SONIC

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-C40-50 |

| Minimum Order Quantity | 1set |

Graphene dispersion purpose

There are a lot of graphite materials in nature, and graphite with a thickness of 1 mm contains about 3 million layers of graphene. Single-layer graphite is called graphene, which does not exist in the free state, and it exists in the form of graphite sheets laminated with multiple layers of graphene. Since the interlayer force of the graphite sheet is weak, it can be exfoliated layer by layer by external force, thereby obtaining a single-layer graphene with a thickness of only one carbon atom.

Ultrasonic-assisted liquid phase exfoliation greatly improves the efficiency of graphene extraction.The application of ultrasonic equipment in the preparation of graphene is mainly in the volumetric thermal layer method and the redox method. These two methods are simpler to operate and cost less than other preparation methods. Due to the cavitation in the liquid, the micro-jet, vibration and other phenomena are formed.

The application of ultrasonic equipment in the preparation of graphene is mainly in the volumetric thermal layer method and the redox method. These two methods are simpler to operate and cost less than other preparation methods. Due to the cavitation in the liquid, the micro-jet, vibration and other phenomena are formed.

1. Reliable for heavy duty sonication processes

2. 24*7 hours continuous operation

3. Industrial grade

4. Colored touch display

5. PLC remote control

6. Automatic Frequency tuning

| Model | RPS-C40-50 |

| Frequency | 20Khz |

| Working frequency | 20KHz |

| Rated power | 3KW |

| Working power | 30%-100% of the rated power, the greater load, the greater power. |

| Amplitude | 0-100μm.Adjustable range:50%-100%. |

| Working temperature | <300℃ |

| Ultrasonic cavitation intensity | 0~5(w/cm²) |

| Reactor material | 304/316 stainless steel |

| Working time | 24H/D |

| Packing size | 210*60*160cm |

| G.W. | 330KGS |

Ultrasound Generation: A transducer converts electrical energy into ultrasonic waves, typically at frequencies of 20–40 kHz.

Cavitation Effect:

Ultrasonic waves create microbubbles in the liquid medium.

These bubbles collapse violently, generating intense shear forces, high temperatures, and pressure differentials.

Breaking Agglomerates:

These forces overcome intermolecular attractions, breaking up particle clusters and dispersing them uniformly in the liquid.

Nanomaterials:

Disperses nanoparticles like carbon nanotubes, graphene, and silica in liquids.

Ensures uniform particle size distribution for applications in composites or coatings.

Pharmaceuticals:

Disperses active ingredients in drug formulations for better bioavailability.

Prepares nanoemulsions and liposomes for drug delivery systems.

Cosmetics:

Mixes pigments, emulsifies creams, and stabilizes formulations in skincare and makeup products.

Food and Beverages:

Creates stable emulsions (e.g., oil-in-water emulsions) for flavorings or nutritional supplements.

Chemical Industry:

Disperses pigments in paints, inks, and coatings.

Prepares catalysts for chemical reactions.

Graphene dispersion purpose

There are a lot of graphite materials in nature, and graphite with a thickness of 1 mm contains about 3 million layers of graphene. Single-layer graphite is called graphene, which does not exist in the free state, and it exists in the form of graphite sheets laminated with multiple layers of graphene. Since the interlayer force of the graphite sheet is weak, it can be exfoliated layer by layer by external force, thereby obtaining a single-layer graphene with a thickness of only one carbon atom.

Ultrasonic-assisted liquid phase exfoliation greatly improves the efficiency of graphene extraction.The application of ultrasonic equipment in the preparation of graphene is mainly in the volumetric thermal layer method and the redox method. These two methods are simpler to operate and cost less than other preparation methods. Due to the cavitation in the liquid, the micro-jet, vibration and other phenomena are formed.

The application of ultrasonic equipment in the preparation of graphene is mainly in the volumetric thermal layer method and the redox method. These two methods are simpler to operate and cost less than other preparation methods. Due to the cavitation in the liquid, the micro-jet, vibration and other phenomena are formed.

1. Reliable for heavy duty sonication processes

2. 24*7 hours continuous operation

3. Industrial grade

4. Colored touch display

5. PLC remote control

6. Automatic Frequency tuning

| Model | RPS-C40-50 |

| Frequency | 20Khz |

| Working frequency | 20KHz |

| Rated power | 3KW |

| Working power | 30%-100% of the rated power, the greater load, the greater power. |

| Amplitude | 0-100μm.Adjustable range:50%-100%. |

| Working temperature | <300℃ |

| Ultrasonic cavitation intensity | 0~5(w/cm²) |

| Reactor material | 304/316 stainless steel |

| Working time | 24H/D |

| Packing size | 210*60*160cm |

| G.W. | 330KGS |

Ultrasound Generation: A transducer converts electrical energy into ultrasonic waves, typically at frequencies of 20–40 kHz.

Cavitation Effect:

Ultrasonic waves create microbubbles in the liquid medium.

These bubbles collapse violently, generating intense shear forces, high temperatures, and pressure differentials.

Breaking Agglomerates:

These forces overcome intermolecular attractions, breaking up particle clusters and dispersing them uniformly in the liquid.

Nanomaterials:

Disperses nanoparticles like carbon nanotubes, graphene, and silica in liquids.

Ensures uniform particle size distribution for applications in composites or coatings.

Pharmaceuticals:

Disperses active ingredients in drug formulations for better bioavailability.

Prepares nanoemulsions and liposomes for drug delivery systems.

Cosmetics:

Mixes pigments, emulsifies creams, and stabilizes formulations in skincare and makeup products.

Food and Beverages:

Creates stable emulsions (e.g., oil-in-water emulsions) for flavorings or nutritional supplements.

Chemical Industry:

Disperses pigments in paints, inks, and coatings.

Prepares catalysts for chemical reactions.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment