loading

| Quantity: | |

| Place of Origin | CHINA |

|---|---|

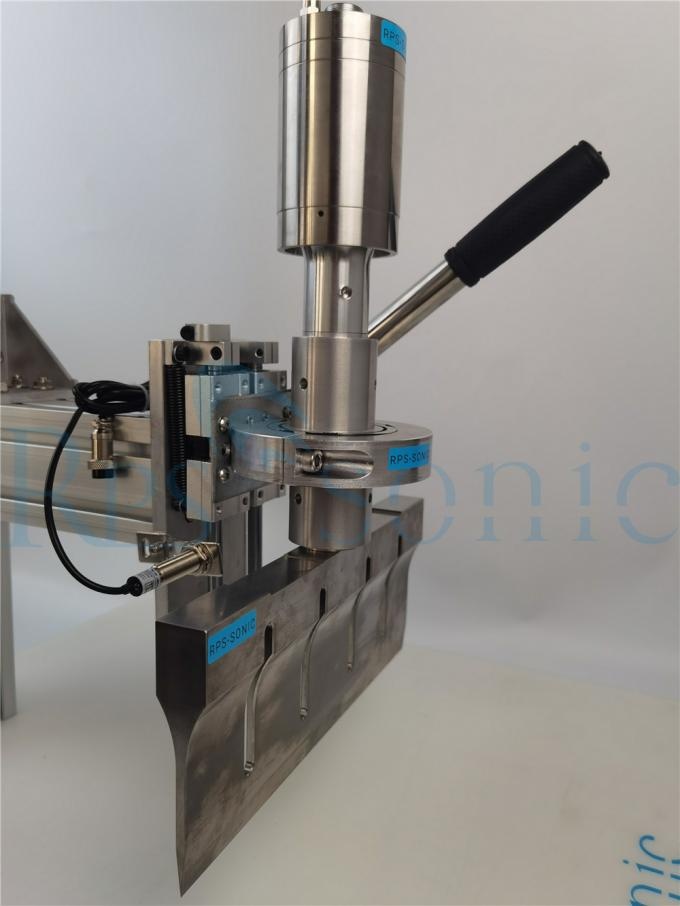

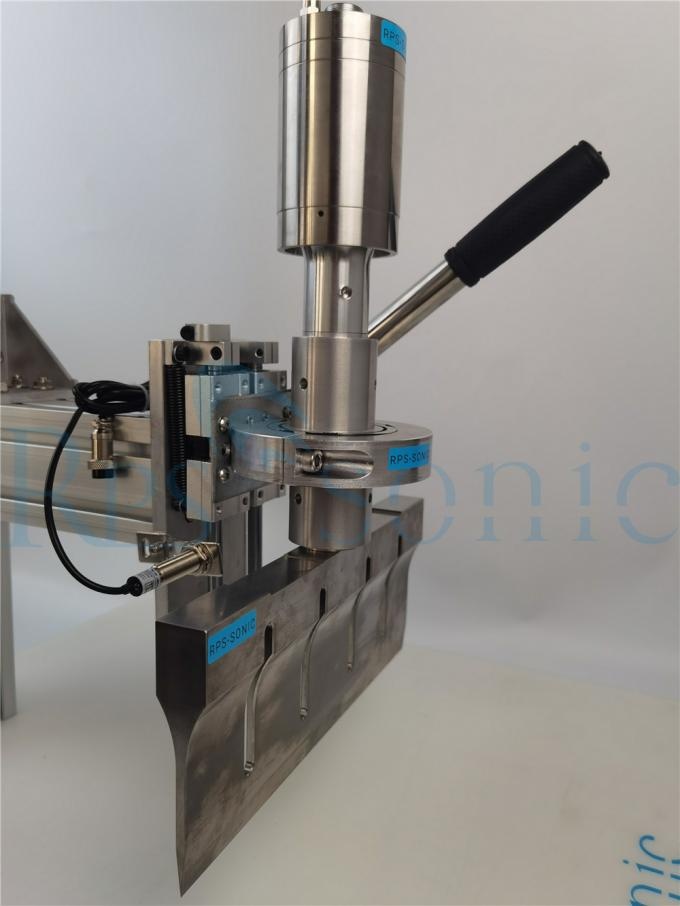

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-C20 |

| Minimum Order Quantity | 1 SET |

| Price | Negotiation |

| Packaging Details | FOAM & CARTON |

| Delivery Time | 3 DAYS after Payment |

| Payment Terms | T/T, Western Union, MoneyGram, PAYPAL |

| Supply Ability | 500 SETS PER MONTH |

| Name | Ultrasonic Cutting Equipment | Frequency | 20Khz |

|---|---|---|---|

| Power | 2000w | Shell Material | TC4 |

| Operate Way | Hand Pressure | Cutter Head Width | 305mm |

| High Light | 305mm ultrasonic cutting knife,ultrasonic cutting knife 20Khz,2000w ultrasonic cutting knife | ||

Rps-sonic offers special ultrasonic vibrating blades to cut all specific products for food industries as fixed weight portion cheeses all shapes, frozen cakes, frozen tarts in molds and complex products. Very attractive prices are done to offer an easy access to this new technology.

The ultrasonic cutting is then perfectly suited to slice :

Cheeses slicing: wheel, block, cheddar, feta, mozzarella, parsley block, cheese log, …

Cooked meat cutting: pate, ham, parsley ham, foie gras, quiche, pie, …

Pastries portioning: pie, dessert, cake, gingerbread, cookie, puff pastry, …

Confectioneries slicing: nougat, fruit paste, caramel, almond paste, fruit candy, cereal bars, chocolate, marshmallow, ganache, brittle, …

Servings and delis: wraps, sushis, sandwiches, …

Frozen foods: all kinds,

Fixed weight: for pre-packed, for important savings throught an accurate control of the sold product.

Welcome automation ultrasonics cutting systerm cooperate with us all over the world.

| Machine | Ultrasonic rubber/cake Cutter |

| Frequency(KHz) | 20Khz |

| Power | 2000 W |

| Cutting Blade / Horn | Titanium |

| Voltage(V) | 220V |

| The width of blade | depend on your requirement |

| Cutting thickness | 10~20mm(depend on materials) |

| Horn amplitude | 10-40μm |

| Equipment weight | 1KG |

1. Ultrasonic processing is an efficient way to cut, slice, divert, align or transfer a variety of products.

It involves a vibrating blade producing a nearly frictionless surface with the influence of ultrasonic which does

not deform products and to which they do not stick. The vibrating frictionless blade cuts or slits products

cleanly such as nuts, raisins, dried fruit or chocolate morsels without displacement or plowing.

2.Ultrasonic vibration reduces friction resistance between the blade and mterial, and it makes the blade cut

smoothly without deformation.The cutting blade is made of titanium (or the material according to your requir

-ement ). It is completely inert and enduring material.

2.The use of ultrasonic cutting , incision aesthetic integrity, trimming neatly smooth, without Burr, to leave the

border areas, not black, not burned, not the hardware products to feel very good shear results

3.It can be used for cake, frozen food, cheese,ect.

Composition of ultrasonic food cutting knife

Ultrasound power supply is also called generator, which converts 50/60 Hz AC voltage into high frequency electric energy. Depending on the application, the frequency can be 20KHz, 30KHz or 40KHz. At 20KHz, the tool head (blade) vibrates 20,000 times per second.

Transducer, a sealed electromechanical device, receives power from a power source and converts it into high-frequency mechanical vibration.

The horn is located between the transducer and the tool head (blade). The output amplitude of the transducer is amplified or reduced, and the appropriate amplitude is transmitted to the tool head (blade).

Tool heads, also known as blades in cutting equipment, are customized for specific applications.

Typical ultrasonic food cutting components include four major elements: a power supply, a converter, a booster and a cutting horn, as explained below.

The attraction of ultrasonic cutting

As always with our ultrasonic cutting, slicing, portioning machines, the benefits and options you will find are for instance:

| Name | Ultrasonic Cutting Equipment | Frequency | 20Khz |

|---|---|---|---|

| Power | 2000w | Shell Material | TC4 |

| Operate Way | Hand Pressure | Cutter Head Width | 305mm |

| High Light | 305mm ultrasonic cutting knife,ultrasonic cutting knife 20Khz,2000w ultrasonic cutting knife | ||

Rps-sonic offers special ultrasonic vibrating blades to cut all specific products for food industries as fixed weight portion cheeses all shapes, frozen cakes, frozen tarts in molds and complex products. Very attractive prices are done to offer an easy access to this new technology.

The ultrasonic cutting is then perfectly suited to slice :

Cheeses slicing: wheel, block, cheddar, feta, mozzarella, parsley block, cheese log, …

Cooked meat cutting: pate, ham, parsley ham, foie gras, quiche, pie, …

Pastries portioning: pie, dessert, cake, gingerbread, cookie, puff pastry, …

Confectioneries slicing: nougat, fruit paste, caramel, almond paste, fruit candy, cereal bars, chocolate, marshmallow, ganache, brittle, …

Servings and delis: wraps, sushis, sandwiches, …

Frozen foods: all kinds,

Fixed weight: for pre-packed, for important savings throught an accurate control of the sold product.

Welcome automation ultrasonics cutting systerm cooperate with us all over the world.

| Machine | Ultrasonic rubber/cake Cutter |

| Frequency(KHz) | 20Khz |

| Power | 2000 W |

| Cutting Blade / Horn | Titanium |

| Voltage(V) | 220V |

| The width of blade | depend on your requirement |

| Cutting thickness | 10~20mm(depend on materials) |

| Horn amplitude | 10-40μm |

| Equipment weight | 1KG |

1. Ultrasonic processing is an efficient way to cut, slice, divert, align or transfer a variety of products.

It involves a vibrating blade producing a nearly frictionless surface with the influence of ultrasonic which does

not deform products and to which they do not stick. The vibrating frictionless blade cuts or slits products

cleanly such as nuts, raisins, dried fruit or chocolate morsels without displacement or plowing.

2.Ultrasonic vibration reduces friction resistance between the blade and mterial, and it makes the blade cut

smoothly without deformation.The cutting blade is made of titanium (or the material according to your requir

-ement ). It is completely inert and enduring material.

2.The use of ultrasonic cutting , incision aesthetic integrity, trimming neatly smooth, without Burr, to leave the

border areas, not black, not burned, not the hardware products to feel very good shear results

3.It can be used for cake, frozen food, cheese,ect.

Composition of ultrasonic food cutting knife

Ultrasound power supply is also called generator, which converts 50/60 Hz AC voltage into high frequency electric energy. Depending on the application, the frequency can be 20KHz, 30KHz or 40KHz. At 20KHz, the tool head (blade) vibrates 20,000 times per second.

Transducer, a sealed electromechanical device, receives power from a power source and converts it into high-frequency mechanical vibration.

The horn is located between the transducer and the tool head (blade). The output amplitude of the transducer is amplified or reduced, and the appropriate amplitude is transmitted to the tool head (blade).

Tool heads, also known as blades in cutting equipment, are customized for specific applications.

Typical ultrasonic food cutting components include four major elements: a power supply, a converter, a booster and a cutting horn, as explained below.

The attraction of ultrasonic cutting

As always with our ultrasonic cutting, slicing, portioning machines, the benefits and options you will find are for instance:

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!