loading

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-W35 |

| Minimum Order Quantity | 1SET |

| Packaging Details | Wooden box |

| Payment Terms | T/T |

| Frequency | 35Khz | Power | 500W, 800W,1000W,2000W |

|---|---|---|---|

| Genenrator | Digital Generator | Horn Material | Titanium,Rapid Steel |

| Application | Tape,belt,bra Welding Machine | ||

| High Light | 2kW 35Khz Ultrasonic Welding Machine,Tape 35Khz Ultrasonic Welding Machine,Belt 35Khz Ultrasonic Welding Machine | ||

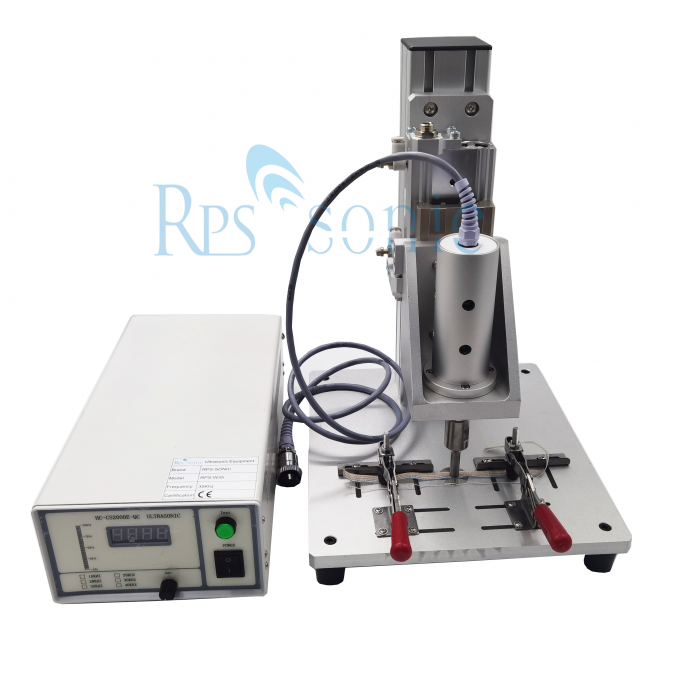

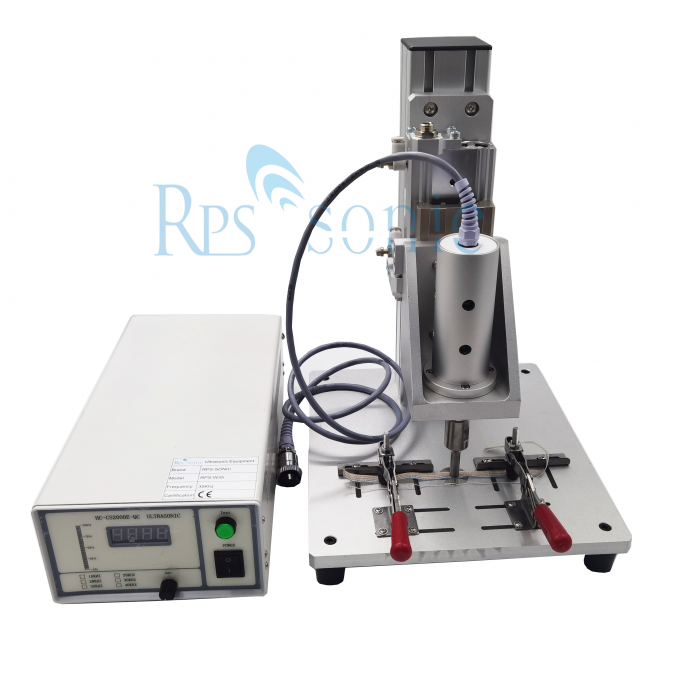

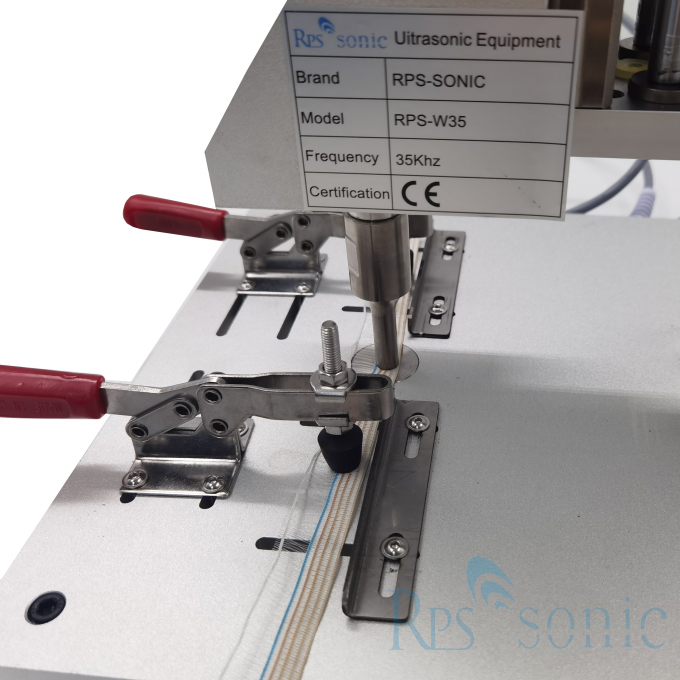

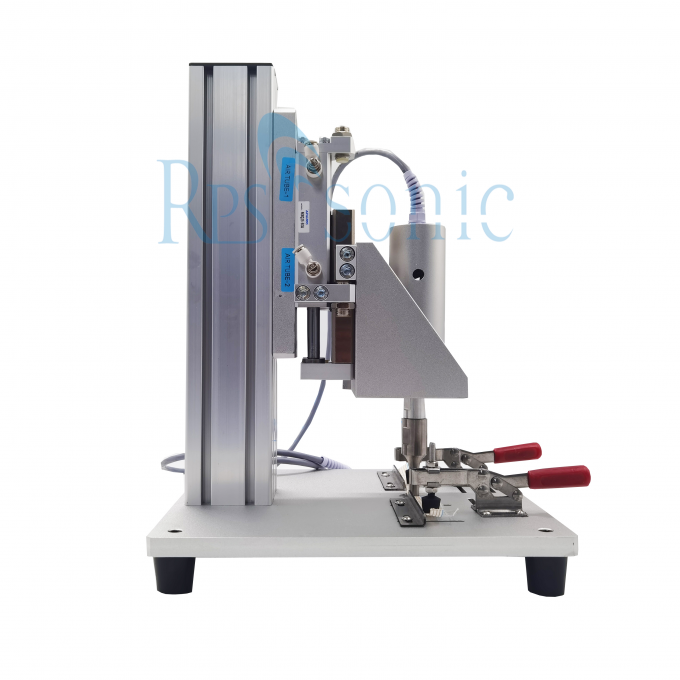

New Arrival : 35Khz Ultrasonic Tape,Belt,Bra Welding Machine

35Khz Ultrasonic tape,belt,bra welding machine

Description:

Ultrasonic welding is an industrial process whereby high-frequency ultrasonic acoustic vibrations are locally applied to workpieces being held together under pressure to create a solid-state weld. It is commonly used for plastics and metals, and especially for joining dissimilar materials. In ultrasonic welding, there are no connective bolts, nails, soldering materials, or adhesives necessary to bind the materials together. When applied to metals, a notable characteristic of this method is that the temperature stays well below the melting point of the involved materials thus preventing any unwanted properties which may arise from high temperature exposure of the materials

Ultrasonic spot welding machines are widely used in the plastic industry around the world. The working principle of ultrasonic spot welding machines is to use the high-voltage and high-frequency signals generated by the generator to convert them into high-frequency vibration through the energy conversion system and add them to plastic products. On the surface, the friction between the workpiece surface and the internal molecules is generated by vibration at the interface. When the temperature reaches the melting point of the workpiece, the workpiece interface rapidly melts, then fills the gap between the interfaces. After the vibration stops, the workpiece is cooled and formed under a certain pressure To achieve perfect welding. Ultrasonic welding is an advanced process for joining plastic parts due to its fast, clean, and safe advantages. This technology can replace the solvents, adhesives, studs or other mechanical fixing methods used in the past. Applying this technology can improve production efficiency ,lower the cost.

Main Features:

1. Imported high quality ultrasonic transducer which power and stable.

2. Excellent sharp design, square saved.

3. Power is 800W,there must be a right type for ur use.

4. Essential part was assembled by imported component.

5. Little noise, pro-environment.

6. Newly developed portable design, more convenient for operation and carrying.

7. Dual working way on by both hand and foot, flexible and practical.

8. Has an excellent frequency tracking performance by the patent owned closing negative feedback loop frequency automatic tracking system.

9. Special design and price, complete plastic outer skin, complete aluminum inner core, membrane switch control panel.

10. We can design the hand horn according to customers' need.

Application of ultrasonic spot welding machine:

For decoration, ribbon spot welding, riveting, etc., portable spot welding machines are widely used in the clothing industry, trademark industry, automotive industry, plastic electronics, household goods industry, etc. Simple operation, high price and practical advantages.

Apparel industry: sewing process of underwear and underwear, welding of webbing elastic band, etc .; can be used for spot drilling.

Trademark industry: woven ribbons, printed ribbons, etc.

Automotive industry: door sound insulation cotton, wiper seat, engine cover, water tank cover, etc.

Plastic electronics: small plastic parts riveting, etc.

Houseware industry: fiber cotton spot welding and so on.

Why choose us :

1. Every transducer with a only tracking number, you can check the parameter from our saler no matter how long it passed.

2. All transducer with one year warranty.

3. Specialized in ultrasound for more than ten years

4. Every transducer with 24hours old testing before shipment.

5. Good packing, no packing problem during the 10 years exporting business.

6. Every customer will get purchase records and there are certain rewards after accumulation

Parameters:

| Item | RPS-W35 |

| Frequency | 35Khz |

| Power | 500W,800W,1000W,2000W |

| Vibration method | Self-extraction |

| Welding time | 0.01-9.99sec |

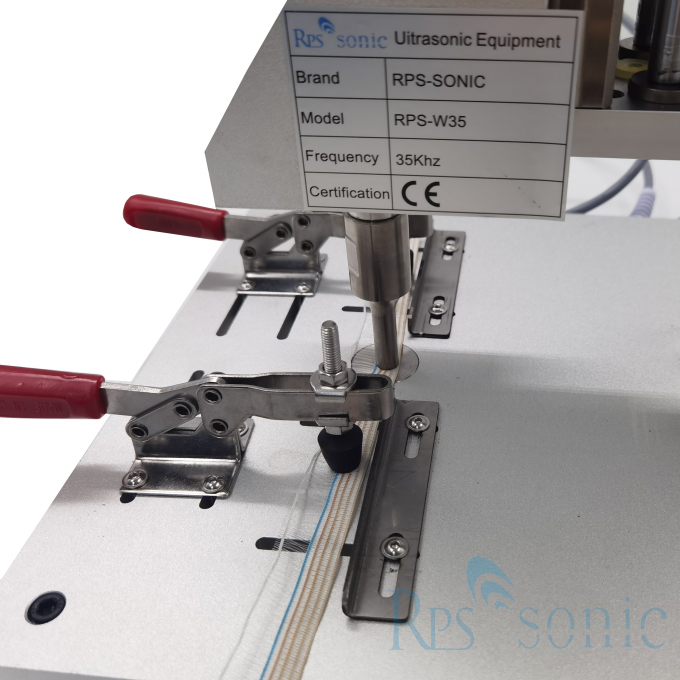

| Horn | Grid horn |

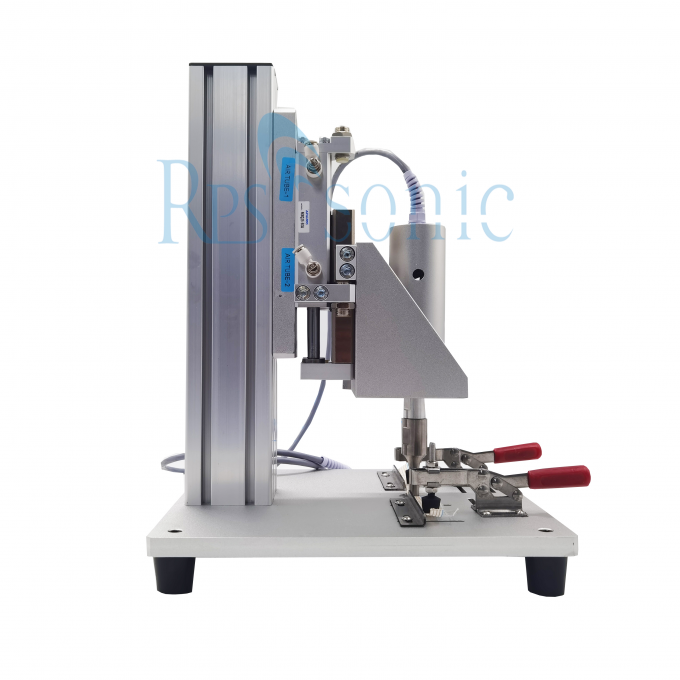

Product pictures:

| Frequency | 35Khz | Power | 500W, 800W,1000W,2000W |

|---|---|---|---|

| Genenrator | Digital Generator | Horn Material | Titanium,Rapid Steel |

| Application | Tape,belt,bra Welding Machine | ||

| High Light | 2kW 35Khz Ultrasonic Welding Machine,Tape 35Khz Ultrasonic Welding Machine,Belt 35Khz Ultrasonic Welding Machine | ||

New Arrival : 35Khz Ultrasonic Tape,Belt,Bra Welding Machine

35Khz Ultrasonic tape,belt,bra welding machine

Description:

Ultrasonic welding is an industrial process whereby high-frequency ultrasonic acoustic vibrations are locally applied to workpieces being held together under pressure to create a solid-state weld. It is commonly used for plastics and metals, and especially for joining dissimilar materials. In ultrasonic welding, there are no connective bolts, nails, soldering materials, or adhesives necessary to bind the materials together. When applied to metals, a notable characteristic of this method is that the temperature stays well below the melting point of the involved materials thus preventing any unwanted properties which may arise from high temperature exposure of the materials

Ultrasonic spot welding machines are widely used in the plastic industry around the world. The working principle of ultrasonic spot welding machines is to use the high-voltage and high-frequency signals generated by the generator to convert them into high-frequency vibration through the energy conversion system and add them to plastic products. On the surface, the friction between the workpiece surface and the internal molecules is generated by vibration at the interface. When the temperature reaches the melting point of the workpiece, the workpiece interface rapidly melts, then fills the gap between the interfaces. After the vibration stops, the workpiece is cooled and formed under a certain pressure To achieve perfect welding. Ultrasonic welding is an advanced process for joining plastic parts due to its fast, clean, and safe advantages. This technology can replace the solvents, adhesives, studs or other mechanical fixing methods used in the past. Applying this technology can improve production efficiency ,lower the cost.

Main Features:

1. Imported high quality ultrasonic transducer which power and stable.

2. Excellent sharp design, square saved.

3. Power is 800W,there must be a right type for ur use.

4. Essential part was assembled by imported component.

5. Little noise, pro-environment.

6. Newly developed portable design, more convenient for operation and carrying.

7. Dual working way on by both hand and foot, flexible and practical.

8. Has an excellent frequency tracking performance by the patent owned closing negative feedback loop frequency automatic tracking system.

9. Special design and price, complete plastic outer skin, complete aluminum inner core, membrane switch control panel.

10. We can design the hand horn according to customers' need.

Application of ultrasonic spot welding machine:

For decoration, ribbon spot welding, riveting, etc., portable spot welding machines are widely used in the clothing industry, trademark industry, automotive industry, plastic electronics, household goods industry, etc. Simple operation, high price and practical advantages.

Apparel industry: sewing process of underwear and underwear, welding of webbing elastic band, etc .; can be used for spot drilling.

Trademark industry: woven ribbons, printed ribbons, etc.

Automotive industry: door sound insulation cotton, wiper seat, engine cover, water tank cover, etc.

Plastic electronics: small plastic parts riveting, etc.

Houseware industry: fiber cotton spot welding and so on.

Why choose us :

1. Every transducer with a only tracking number, you can check the parameter from our saler no matter how long it passed.

2. All transducer with one year warranty.

3. Specialized in ultrasound for more than ten years

4. Every transducer with 24hours old testing before shipment.

5. Good packing, no packing problem during the 10 years exporting business.

6. Every customer will get purchase records and there are certain rewards after accumulation

Parameters:

| Item | RPS-W35 |

| Frequency | 35Khz |

| Power | 500W,800W,1000W,2000W |

| Vibration method | Self-extraction |

| Welding time | 0.01-9.99sec |

| Horn | Grid horn |

Product pictures:

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!