loading

| Place of Origin | China |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

| Model Number | RPS-C20-305 |

| Minimum Order Quantity | 1pcs |

| Price | Negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

| Frequency | 20Khz | Power | 1000w |

|---|---|---|---|

| Blade Material | Titanium | Blade Size | 305mm |

| Weight | 25kg | Package | Wooden |

| Height | 65mm | ||

| High Light | Titanium Ultrasonic Food Cutting Machine,1kw Ultrasonic Food Cutting Machine,Titanium Ultrasonic Cake Cutter | ||

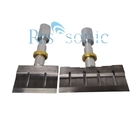

20Khz 1000w Ultrasonic food cutting machine for frozen food cutting

Parameter

| Machine | Ultrasonic cake Cutter |

| Frequency(KHz) | 20Khz |

| Power | 1000 W |

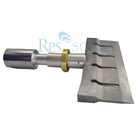

| Cutting Blade / Horn | Titanium |

| Voltage(V) | 220V |

| The width of blade | depend on your requirement |

| Cutting thickness | 10~20mm(depend on materials) |

| Horn amplitude | 10-40μm |

| Equipment weight | 25KG |

Description

Over the years, the minimal demand for processed foods by the food industry has led to significant changes in processing methods, as some processing techniques reduce their nutrient levels and bioavailability by inducing physical and chemical changes under critical conditions, thereby reducing organoleptic acceptability. sex. Therefore, in order to preserve nutritional, non-nutritive (bioactive) and organoleptic properties, the food industry has devised newer gentle processing methods to replace these techniques. Ultrasonics is one of the rapidly developing technologies aimed at reducing processing, improving quality and ensuring food safety. Ultrasound technology, as a key area of research and development in the food industry, is based on mechanical waves with frequencies above the limit of human hearing (> 16khz), which can be divided into two frequency ranges: low energy and high energy. Low-energy (low-power, low-intensity) ultrasound at frequencies below 1 Wcm−2 above 100 kHz, while high-energy (high-power, high-intensity) ultrasound at frequencies between 20 and 500 kHz higher than 1 Wcm−2.

A representative range of frequencies commonly used in ultrasound technology is between 20 kHz and 60 kHz. As an analytical technique, high-frequency ultrasound is used to obtain information on the physical and chemical properties of food such as acidity, hardness, sugar content, and maturity. Low-frequency ultrasound, on the other hand, alters the physical and chemical properties of food by inducing pressure, shear, and temperature differences in the medium it propagates, and generates vacuoles, thereby inactivating microorganisms in food. Ultrasonic treatment is suitable for pre- and post-harvest quality control of fresh vegetables and fruits, cheese processing, commercial edible oils, bread and cereal products, bulk and emulsified fatty foods, food gels, aerated and frozen foods. Other applications include detection of honey adulteration and assessment of aggregation status, size and protein type. The frequency range of low-frequency ultrasound, as well as the spectrum, nuclear magnetic resonance (NMR) is currently the most popular, practical and widely used non-destructive analysis method. Low-frequency ultrasound has been used successfully for many years to study the physicochemical and structural properties of fluid foods.

Ultrasonic food processing involves ultrasonic food cutting knives (guillotine) to create a virtually frictionless surface where food does not stick or deform. The surface cuts cleanly through products, including fillers such as nuts, raisins, dried fruit or chocolate crumbles, without shifting or ploughing effects. Many of the world's most prestigious food producers use ultrasonic food cutting technology. It is safe and reliable and produces a higher quality finished product with less cleaning or production downtime.

Cutable food

Many factors can affect how well a variety of foods are cut.

cheese

Almost all types of cheese in all shapes can be successfully cut with ultrasound. Soft cheeses with a high moisture content tend to be the most difficult, while hard cheeses with a high fat content work best. Ultrasonic cutting will provide better aesthetics, reduce breakage and damage, and will reduce downtime due to cleaning or product sticking to the blade surface.

bar food

Formed and extruded bars, as well as other non-brittle confectionery products, can be cut with excellent results. Nuts, raisins, and other inclusions usually have little effect on the cutting process. Temperature and recipe play a big role in the success of dairy cutting.

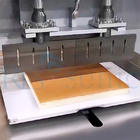

cake

Cakes Multilayer, multi-density cakes are the most common of these types of products. Ultrasound can provide superior, aesthetically pleasing cuts for high-value cakes and bakery products. High-quality aesthetics, reducing product sticking. Soft cream or even inclusions like nuts or raisins can be used.

sandwich

Breads or square sandwiches can be cut with ultrasonics effortlessly. Meat, cheese, vegetables can be chopped evenly and cleanly without disturbing the layers or compressing the bread.

| Frequency | 20Khz | Power | 1000w |

|---|---|---|---|

| Blade Material | Titanium | Blade Size | 305mm |

| Weight | 25kg | Package | Wooden |

| Height | 65mm | ||

| High Light | Titanium Ultrasonic Food Cutting Machine,1kw Ultrasonic Food Cutting Machine,Titanium Ultrasonic Cake Cutter | ||

20Khz 1000w Ultrasonic food cutting machine for frozen food cutting

Parameter

| Machine | Ultrasonic cake Cutter |

| Frequency(KHz) | 20Khz |

| Power | 1000 W |

| Cutting Blade / Horn | Titanium |

| Voltage(V) | 220V |

| The width of blade | depend on your requirement |

| Cutting thickness | 10~20mm(depend on materials) |

| Horn amplitude | 10-40μm |

| Equipment weight | 25KG |

Description

Over the years, the minimal demand for processed foods by the food industry has led to significant changes in processing methods, as some processing techniques reduce their nutrient levels and bioavailability by inducing physical and chemical changes under critical conditions, thereby reducing organoleptic acceptability. sex. Therefore, in order to preserve nutritional, non-nutritive (bioactive) and organoleptic properties, the food industry has devised newer gentle processing methods to replace these techniques. Ultrasonics is one of the rapidly developing technologies aimed at reducing processing, improving quality and ensuring food safety. Ultrasound technology, as a key area of research and development in the food industry, is based on mechanical waves with frequencies above the limit of human hearing (> 16khz), which can be divided into two frequency ranges: low energy and high energy. Low-energy (low-power, low-intensity) ultrasound at frequencies below 1 Wcm−2 above 100 kHz, while high-energy (high-power, high-intensity) ultrasound at frequencies between 20 and 500 kHz higher than 1 Wcm−2.

A representative range of frequencies commonly used in ultrasound technology is between 20 kHz and 60 kHz. As an analytical technique, high-frequency ultrasound is used to obtain information on the physical and chemical properties of food such as acidity, hardness, sugar content, and maturity. Low-frequency ultrasound, on the other hand, alters the physical and chemical properties of food by inducing pressure, shear, and temperature differences in the medium it propagates, and generates vacuoles, thereby inactivating microorganisms in food. Ultrasonic treatment is suitable for pre- and post-harvest quality control of fresh vegetables and fruits, cheese processing, commercial edible oils, bread and cereal products, bulk and emulsified fatty foods, food gels, aerated and frozen foods. Other applications include detection of honey adulteration and assessment of aggregation status, size and protein type. The frequency range of low-frequency ultrasound, as well as the spectrum, nuclear magnetic resonance (NMR) is currently the most popular, practical and widely used non-destructive analysis method. Low-frequency ultrasound has been used successfully for many years to study the physicochemical and structural properties of fluid foods.

Ultrasonic food processing involves ultrasonic food cutting knives (guillotine) to create a virtually frictionless surface where food does not stick or deform. The surface cuts cleanly through products, including fillers such as nuts, raisins, dried fruit or chocolate crumbles, without shifting or ploughing effects. Many of the world's most prestigious food producers use ultrasonic food cutting technology. It is safe and reliable and produces a higher quality finished product with less cleaning or production downtime.

Cutable food

Many factors can affect how well a variety of foods are cut.

cheese

Almost all types of cheese in all shapes can be successfully cut with ultrasound. Soft cheeses with a high moisture content tend to be the most difficult, while hard cheeses with a high fat content work best. Ultrasonic cutting will provide better aesthetics, reduce breakage and damage, and will reduce downtime due to cleaning or product sticking to the blade surface.

bar food

Formed and extruded bars, as well as other non-brittle confectionery products, can be cut with excellent results. Nuts, raisins, and other inclusions usually have little effect on the cutting process. Temperature and recipe play a big role in the success of dairy cutting.

cake

Cakes Multilayer, multi-density cakes are the most common of these types of products. Ultrasound can provide superior, aesthetically pleasing cuts for high-value cakes and bakery products. High-quality aesthetics, reducing product sticking. Soft cream or even inclusions like nuts or raisins can be used.

sandwich

Breads or square sandwiches can be cut with ultrasonics effortlessly. Meat, cheese, vegetables can be chopped evenly and cleanly without disturbing the layers or compressing the bread.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment

content is empty!