loading

| Place of Origin | china |

|---|---|

| Brand Name | RPS-SONIC |

| Certification | CE |

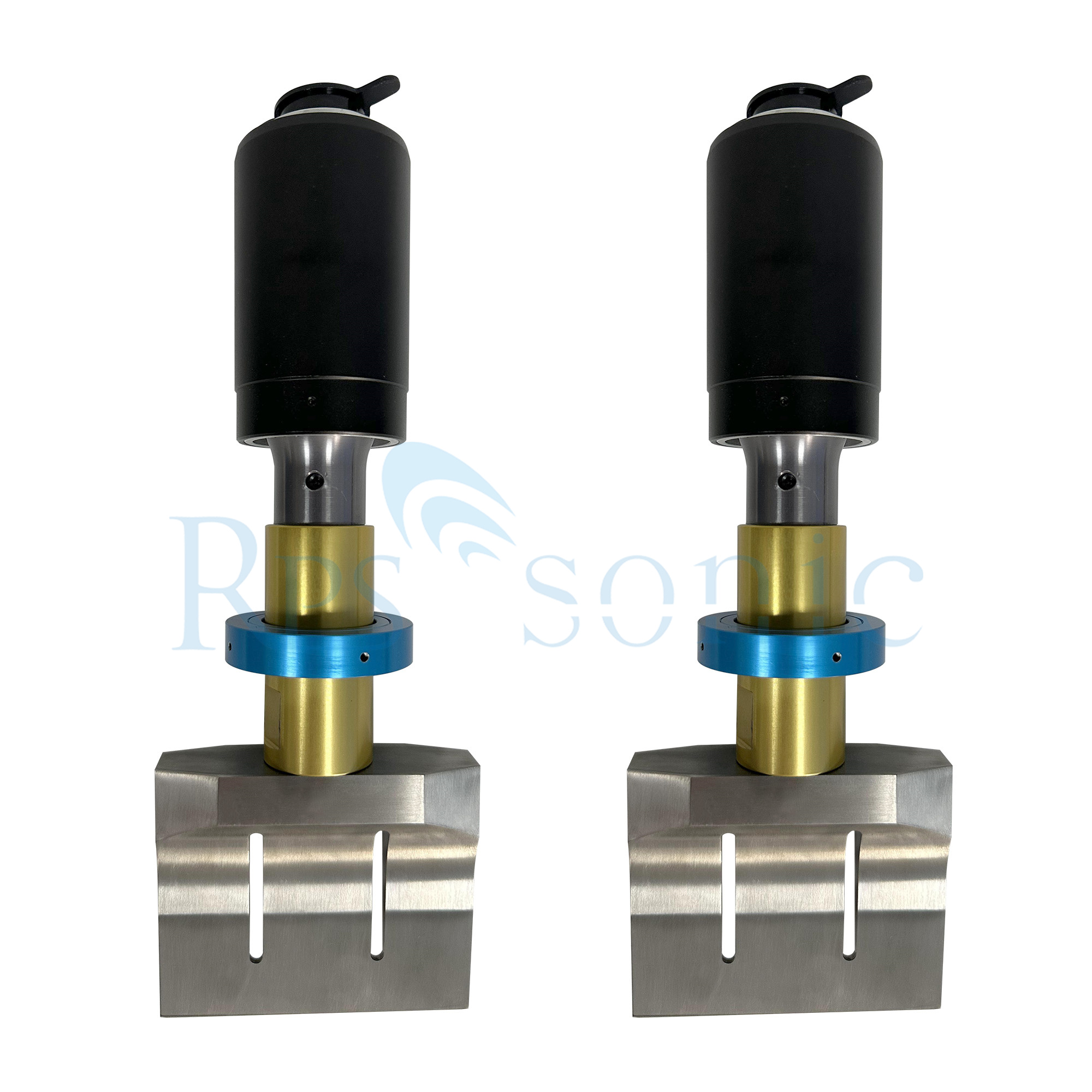

| Model Number | RPS-C40 |

| Minimum Order Quantity | 1 |

| Price | to be negotiated |

| Packaging Details | CARTON |

| Delivery Time | 3-7 WORK DAYS |

| Payment Terms | T/T, D/P, D/A, L/C, Western Union, MoneyGram |

| Supply Ability | 200pcs/month |

| Model | RPS-C40 |

| Frequency | 40khz |

| Power | 500W |

| Generator | Digital generator |

| Input | AC110-240V, 50/60Hz |

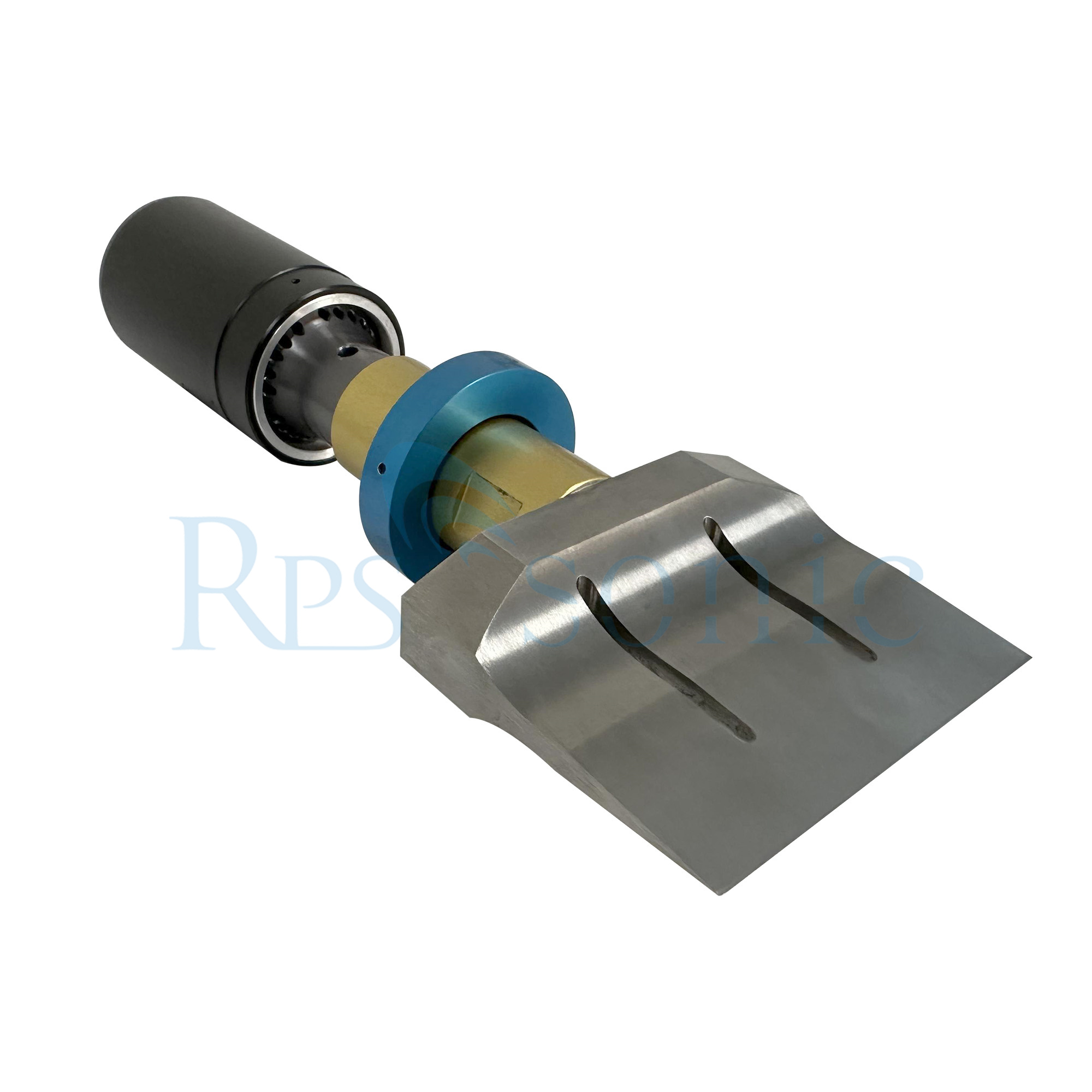

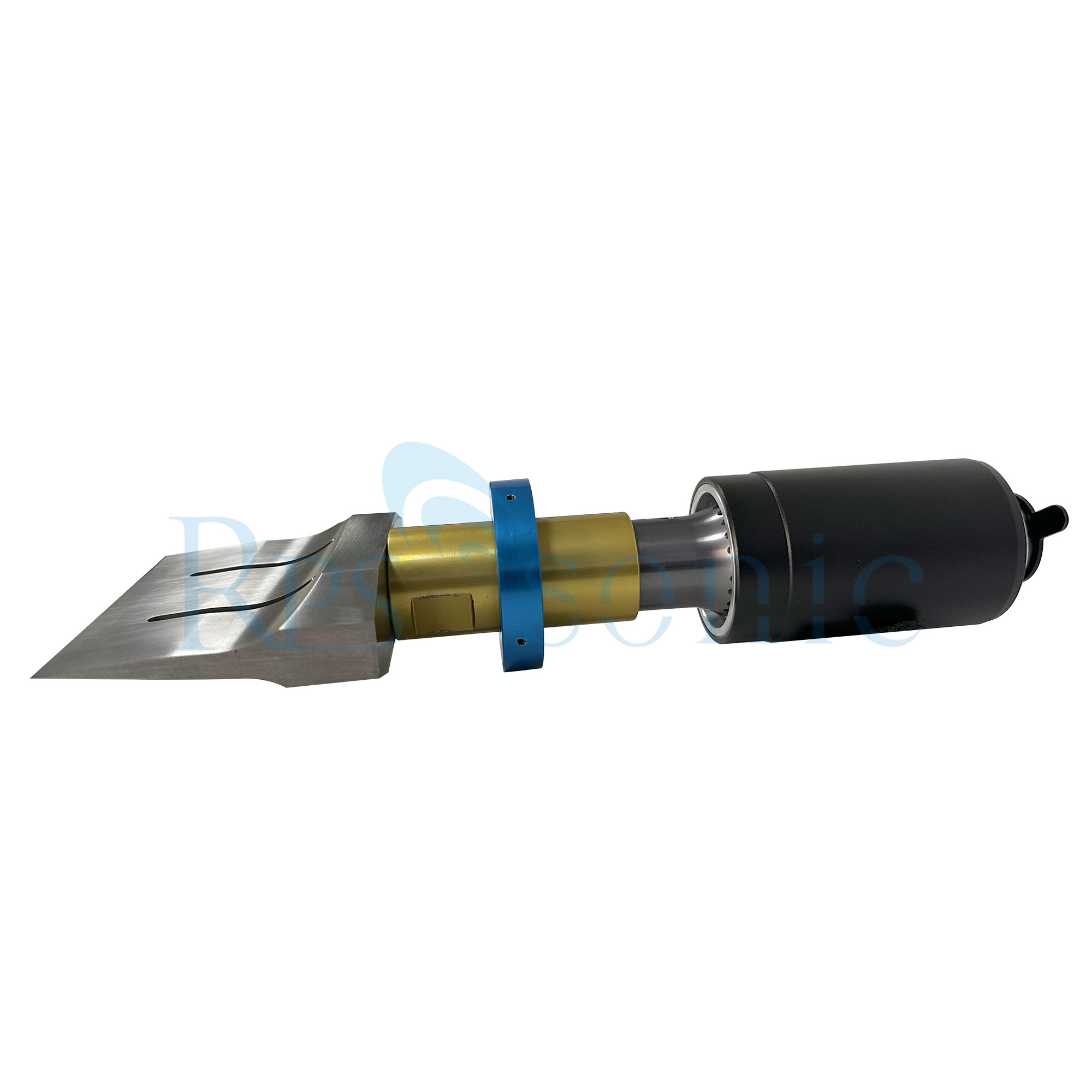

| Width cutter | 82.5mm |

| Material of cutting | Titanium alloy |

| Outer skin | Aluminum |

| Voltage | 220V / 110V |

Ultrasonic rubber cutting uses high-frequency ultrasonic vibrations to cut rubber materials precisely and efficiently. This method is particularly effective for soft, sticky, or flexible rubber types where traditional cutting methods might cause deformation or leave uneven edges.

Clean and Precise Cuts: Prevents distortion or jagged edges, even on soft or flexible rubber.

No Material Sticking: The ultrasonic vibration reduces friction, ensuring the rubber doesn't stick to the blade.

Dust-Free Operation: Ideal for cleanroom environments and industries where cleanliness is critical.

Minimal Waste: Efficient cutting with no tearing or deformation reduces material waste.

Versatility: Effective for various rubber types, including natural rubber, synthetic rubber, silicone, and thermoplastic elastomers.

Automotive Industry:

Cutting gaskets, seals, and rubber components for engines and interiors.

Medical and Pharmaceutical:

Precision cutting of silicone and rubber components for medical devices.

Electronics:

Cutting rubber seals, insulators, and flexible components.

Consumer Goods:

Shaping rubber parts for footwear, appliances, and household products.

| Model | RPS-C40 |

| Frequency | 40khz |

| Power | 500W |

| Generator | Digital generator |

| Input | AC110-240V, 50/60Hz |

| Width cutter | 82.5mm |

| Material of cutting | Titanium alloy |

| Outer skin | Aluminum |

| Voltage | 220V / 110V |

Ultrasonic rubber cutting uses high-frequency ultrasonic vibrations to cut rubber materials precisely and efficiently. This method is particularly effective for soft, sticky, or flexible rubber types where traditional cutting methods might cause deformation or leave uneven edges.

Clean and Precise Cuts: Prevents distortion or jagged edges, even on soft or flexible rubber.

No Material Sticking: The ultrasonic vibration reduces friction, ensuring the rubber doesn't stick to the blade.

Dust-Free Operation: Ideal for cleanroom environments and industries where cleanliness is critical.

Minimal Waste: Efficient cutting with no tearing or deformation reduces material waste.

Versatility: Effective for various rubber types, including natural rubber, synthetic rubber, silicone, and thermoplastic elastomers.

Automotive Industry:

Cutting gaskets, seals, and rubber components for engines and interiors.

Medical and Pharmaceutical:

Precision cutting of silicone and rubber components for medical devices.

Electronics:

Cutting rubber seals, insulators, and flexible components.

Consumer Goods:

Shaping rubber parts for footwear, appliances, and household products.

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment