loading

| Availability: | |

|---|---|

| Quantity: | |

| Place of Origin | China |

|---|---|

| Brand Name | Rps-sonic |

| Certification | CE |

| Model Number | RPS-C40 |

| Minimum Order Quantity | 1pcs |

| Price | negotiable |

| Packaging Details | CARTON |

| Delivery Time | 1DAYS |

| Payment Terms | T/T |

| Supply Ability | 200PCS/MONTH |

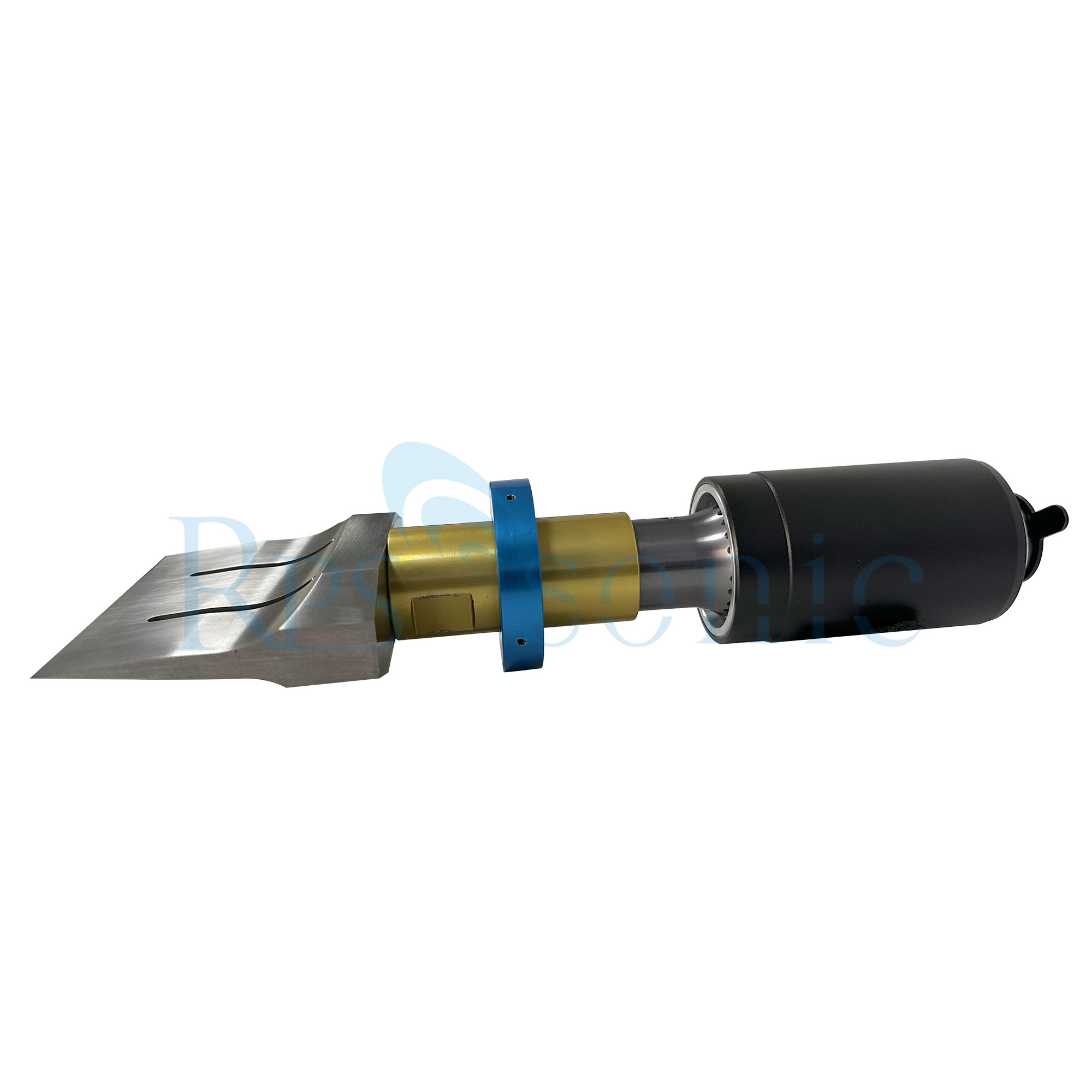

40khz 500w Coutinous working Ultrasonic Rubber cutting device with digital generator

Description

RPS-SONIC ultrasonic cutting knife has a frequency range of 20~40kHz, which is suitable for cutting a variety of materials, including conventional thermoplastic materials, flexible materials such as fabrics, leather and rubber, and high-strength composite materials such as glass fiber, carbon fiber and aramid. With its high-frequency vibration and carbide tip, the Hertz sonic ultrasonic cutting knife provides excellent cutting accuracy and efficiency while maintaining the integrity of the material, making it an ideal choice for multi-purpose cutting in industrial production.

Ultrasonic cutting technology has significant advantages in cutting rubber materials. It uses a high-frequency vibrating cutter head to achieve precise cutting under low temperature conditions, avoiding the problems of rubber deformation, adhesion and uneven edges in traditional cutting. Compared with traditional methods, ultrasonic cutting does not require excessive pressure or high temperatures, ensuring smooth and neat cutting edges, reducing material loss and subsequent processing requirements during the cutting process, and is an efficient solution for rubber product processing.

1. High cutting precision and constant material shape.

2, easy to apply to automated production

3, the cutting surface has good finish and good bonding performance.

4, fast, high efficiency, no pollution.

5. The cutting part adopts the hand-held design. The whole machine is compact, beautiful in appearance and easy to operate. It can replace different size and different material cutting knives to achieve the ideal cutting equipment;

6. Ultrasonic cutting machine adopts hand-held cutting design, which can replace different specifications of cutting knife mold, which is easy to use;

7. The function module with automatic and rapid resonance of detuning can last up to 18 hours in a continuous working time without additional cold going conditions.

8. The ultrasonic power supply independently researched and developed by the company can provide 50% of the performance of the products and prolong the service life of the transducer by more than one time;

9. Ultrasonic vibration reduces the frictional resistance between the blade and the food, which makes the blade cut smoothly, reduces food fragments during the cutting process, and improves production efficiency;

10. Using the vibration handle, the operation is simple and quiet and silent when cutting, no vibration, the cutting is light and the effect is perfect;

11, with high frequency vibration of 40KHZ or 20KHZ, this low friction makes the cutting knife cut food smoothly, making the food cutting surface clean, beautiful and not deformed;

12. It can be used by hand in a single machine, or it can be mounted on a machine to control the cutting head with a computer to form a fully automatic cutting device for the cutting of batch materials in the assembly line.

Ultrasonic Components

Typical ultrasonic food cutting components include four major elements: a power supply, a converter, a booster and a cutting horn, as explained below.

1. Power supply

The ultrasonic power supply, also referred to as a generator, is an electronic device that takes standard 50/60Hz AC line voltage and converts it to high frequency electrical energy.

2. Converter

The ultrasonic converter is a sealed electro/mechanical device that receives the 20kHz electrical energy from the power supply and converts this electrical energy to high frequency mechanical vibrations using PZT(piezoelectric) ceramic discs that expand and contract within the converter housing.

3. Booster

The booster is a machined metal mechanical amplifier that will either raise or lower the amplitude of the horn's mechanical motion depending on the configuration of the masses machined at each end.

4. Cutting horn

The cutting horn, also referred to as a knife or a blade horn, is the component that comes into contact with the product and does the actual cutting. This horn is machined from titanium, has excellent acoustic properties, good surface hardness and superior fatigue value.

Our ultrasonic components and horns are designed for continuous operation under the most demanding production environments. Welcome customers to cooperate with us for a brilliant future!

Parameter

| Machine | Ultrasonic rubber/cake Cutter |

| Frequency(KHz) | 40KHz |

| Power | 500 W |

| Cutting Blade / Horn | Titanium |

| Voltage(V) | 220V |

| The width of blade | 82.5mm |

| Cutting thickness | 10~20mm(depend on materials) |

| Horn amplitude | 10-40μm |

| Equipment weight | 0.6KG |

Application

Frozen cakes and pies

Frozen fish

Snack and health bars

Fresh/frozen prepared meats

Dough or baked cookies

Soft and hard cheeses

Fresh/frozen vegetables

Candy and confections

Ice cream bars

40khz 500w Coutinous working Ultrasonic Rubber cutting device with digital generator

Description

RPS-SONIC ultrasonic cutting knife has a frequency range of 20~40kHz, which is suitable for cutting a variety of materials, including conventional thermoplastic materials, flexible materials such as fabrics, leather and rubber, and high-strength composite materials such as glass fiber, carbon fiber and aramid. With its high-frequency vibration and carbide tip, the Hertz sonic ultrasonic cutting knife provides excellent cutting accuracy and efficiency while maintaining the integrity of the material, making it an ideal choice for multi-purpose cutting in industrial production.

Ultrasonic cutting technology has significant advantages in cutting rubber materials. It uses a high-frequency vibrating cutter head to achieve precise cutting under low temperature conditions, avoiding the problems of rubber deformation, adhesion and uneven edges in traditional cutting. Compared with traditional methods, ultrasonic cutting does not require excessive pressure or high temperatures, ensuring smooth and neat cutting edges, reducing material loss and subsequent processing requirements during the cutting process, and is an efficient solution for rubber product processing.

1. High cutting precision and constant material shape.

2, easy to apply to automated production

3, the cutting surface has good finish and good bonding performance.

4, fast, high efficiency, no pollution.

5. The cutting part adopts the hand-held design. The whole machine is compact, beautiful in appearance and easy to operate. It can replace different size and different material cutting knives to achieve the ideal cutting equipment;

6. Ultrasonic cutting machine adopts hand-held cutting design, which can replace different specifications of cutting knife mold, which is easy to use;

7. The function module with automatic and rapid resonance of detuning can last up to 18 hours in a continuous working time without additional cold going conditions.

8. The ultrasonic power supply independently researched and developed by the company can provide 50% of the performance of the products and prolong the service life of the transducer by more than one time;

9. Ultrasonic vibration reduces the frictional resistance between the blade and the food, which makes the blade cut smoothly, reduces food fragments during the cutting process, and improves production efficiency;

10. Using the vibration handle, the operation is simple and quiet and silent when cutting, no vibration, the cutting is light and the effect is perfect;

11, with high frequency vibration of 40KHZ or 20KHZ, this low friction makes the cutting knife cut food smoothly, making the food cutting surface clean, beautiful and not deformed;

12. It can be used by hand in a single machine, or it can be mounted on a machine to control the cutting head with a computer to form a fully automatic cutting device for the cutting of batch materials in the assembly line.

Ultrasonic Components

Typical ultrasonic food cutting components include four major elements: a power supply, a converter, a booster and a cutting horn, as explained below.

1. Power supply

The ultrasonic power supply, also referred to as a generator, is an electronic device that takes standard 50/60Hz AC line voltage and converts it to high frequency electrical energy.

2. Converter

The ultrasonic converter is a sealed electro/mechanical device that receives the 20kHz electrical energy from the power supply and converts this electrical energy to high frequency mechanical vibrations using PZT(piezoelectric) ceramic discs that expand and contract within the converter housing.

3. Booster

The booster is a machined metal mechanical amplifier that will either raise or lower the amplitude of the horn's mechanical motion depending on the configuration of the masses machined at each end.

4. Cutting horn

The cutting horn, also referred to as a knife or a blade horn, is the component that comes into contact with the product and does the actual cutting. This horn is machined from titanium, has excellent acoustic properties, good surface hardness and superior fatigue value.

Our ultrasonic components and horns are designed for continuous operation under the most demanding production environments. Welcome customers to cooperate with us for a brilliant future!

Parameter

| Machine | Ultrasonic rubber/cake Cutter |

| Frequency(KHz) | 40KHz |

| Power | 500 W |

| Cutting Blade / Horn | Titanium |

| Voltage(V) | 220V |

| The width of blade | 82.5mm |

| Cutting thickness | 10~20mm(depend on materials) |

| Horn amplitude | 10-40μm |

| Equipment weight | 0.6KG |

Application

Frozen cakes and pies

Frozen fish

Snack and health bars

Fresh/frozen prepared meats

Dough or baked cookies

Soft and hard cheeses

Fresh/frozen vegetables

Candy and confections

Ice cream bars

Ultrasonic Welding Equipment Ultrasonic Welding Transducer Ultrasonic Welding Converter Ultrasonic Liquid Processor Ultrasonic Cutting Equipment Ultrasonic Spray Nozzles Ultrasonic Power Supply Ultrasonic Soldering Equipment Ultrasonic Welding Horn Ultrasonic Assisted Machining Ultrasonic Testing Equipment